Hollow tire body for cast-in-situ concrete filling

A technology of hollow carcass and cast-in-place concrete, which is applied to floors, building materials, building components, etc., and can solve problems such as low production efficiency, inconvenient assembly line production, and inconvenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

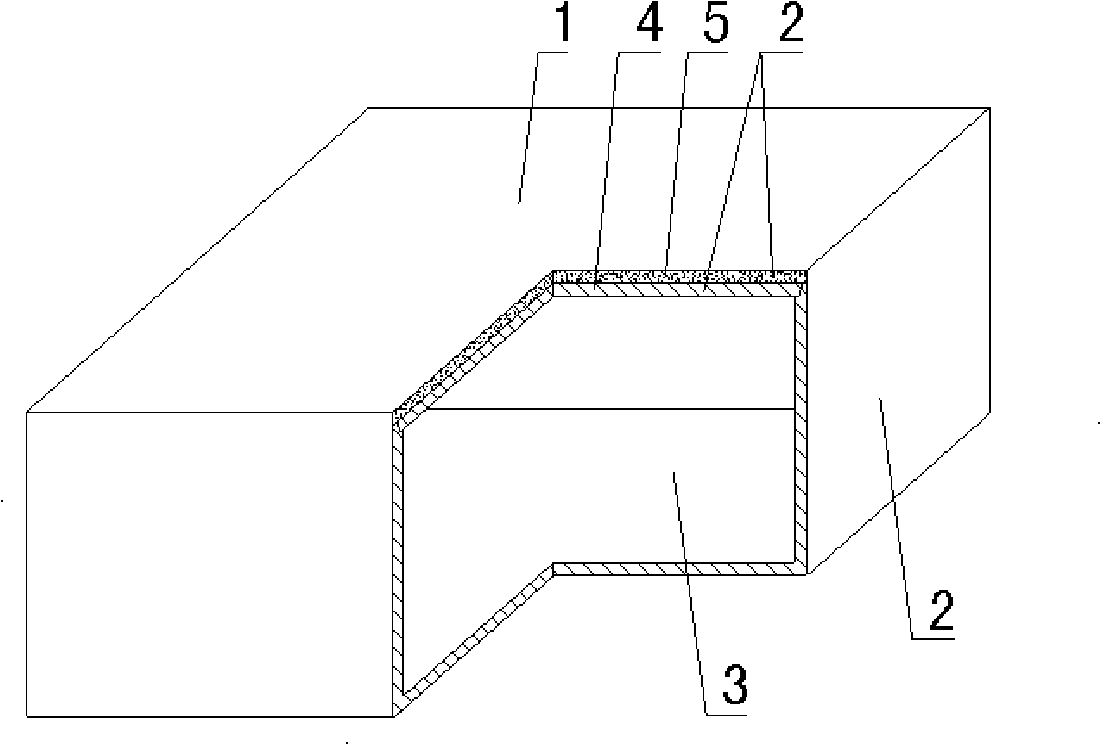

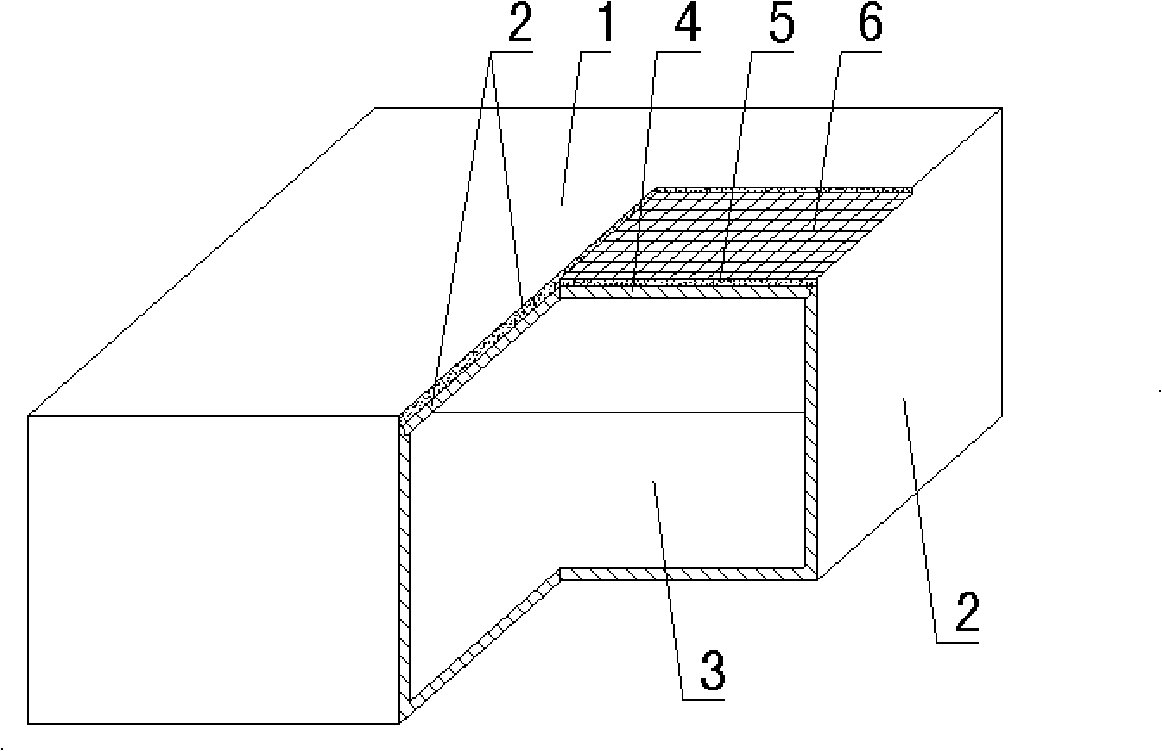

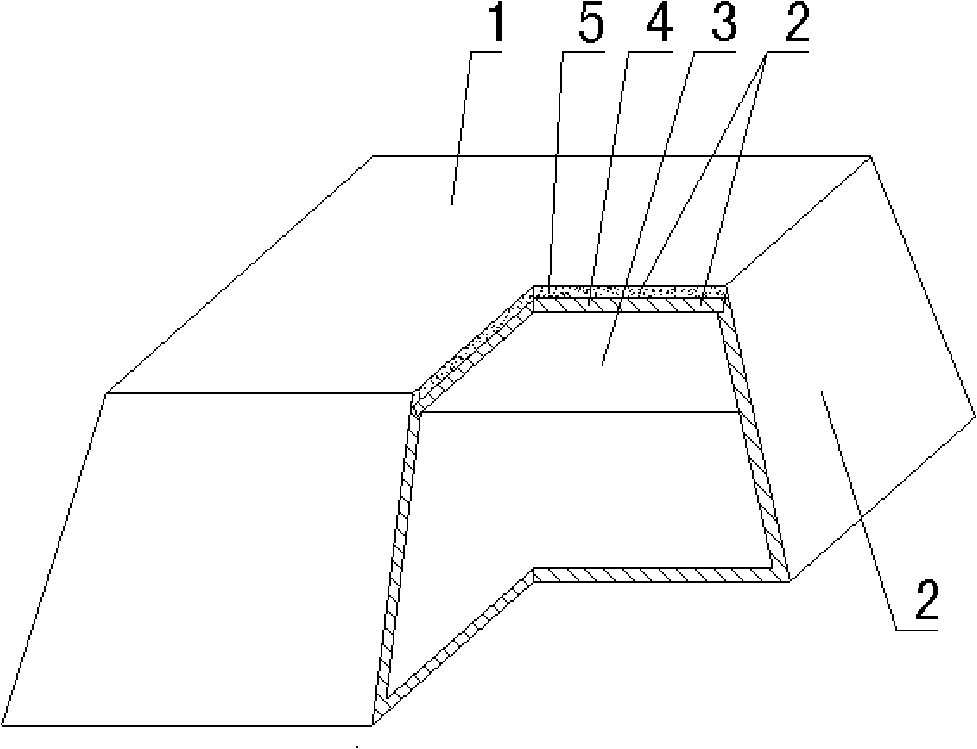

[0072]As shown in the accompanying drawings, the present invention includes a hollow carcass 1, which is formed by surrounding an outer wall 2 and has a cavity 3 inside, and is characterized in that at least one outer wall 2 of the hollow carcass 1 is prefabricated The board wall 4 and the slurry embryo body 5 are made of soft and hard laminated and cemented, and the prefabricated board wall 4 and the slurry embryo body 5 are laminated and solidified with the inner hard and outer soft, and there is a hollow rod for strengthening the upper and lower outer walls. The two ports of the rod communicate with the exterior of the upper and lower outer walls 2 to form a connected hole 17 . In the accompanying drawings, 1 is the hollow carcass, 2 is the outer wall, 3 is the cavity, 4 is the prefabricated board wall, and 5 is the slurry body. In the following draw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com