Gear torsional moment converter and reciprocating piston power machine for gear transmission

A technology of torque converter and gear transmission, which is applied in transmission devices, engine components, friction transmission devices, etc., can solve the problems of many rotating components and high manufacturing costs, achieve small friction loss and waste work loss, reduce heat pollution, and be easy to implement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] (1) Implementation of gear torque converter:

[0060] 1. Implementation of Shaft Gear Torque Converter:

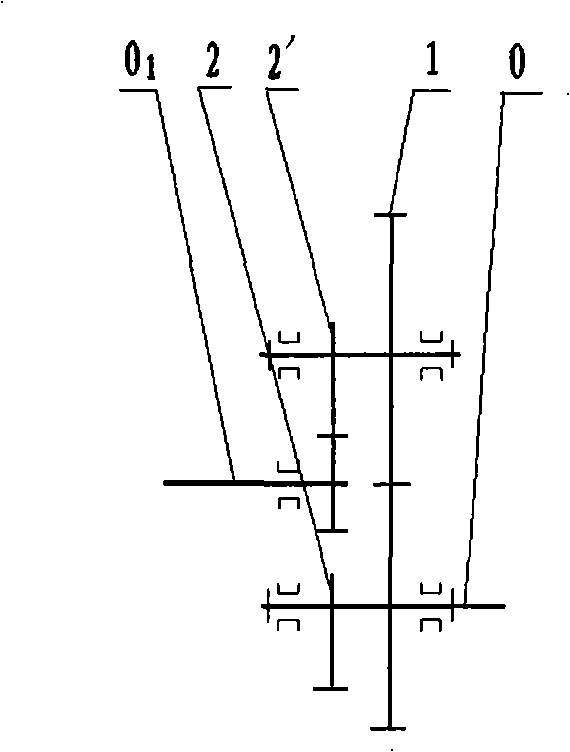

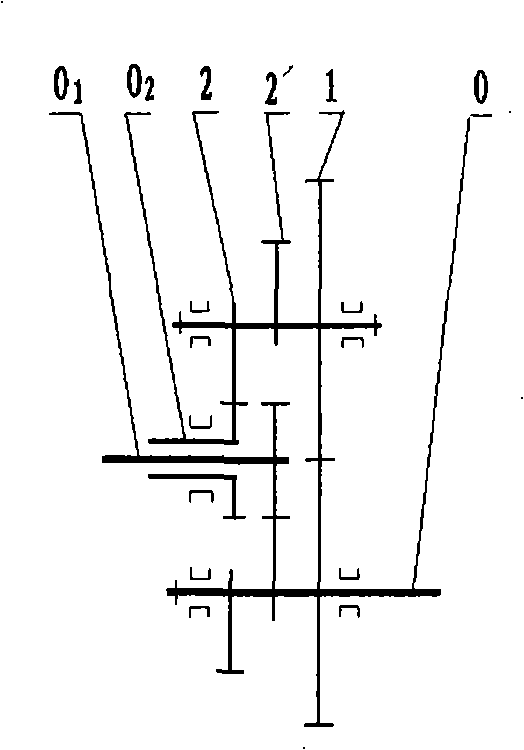

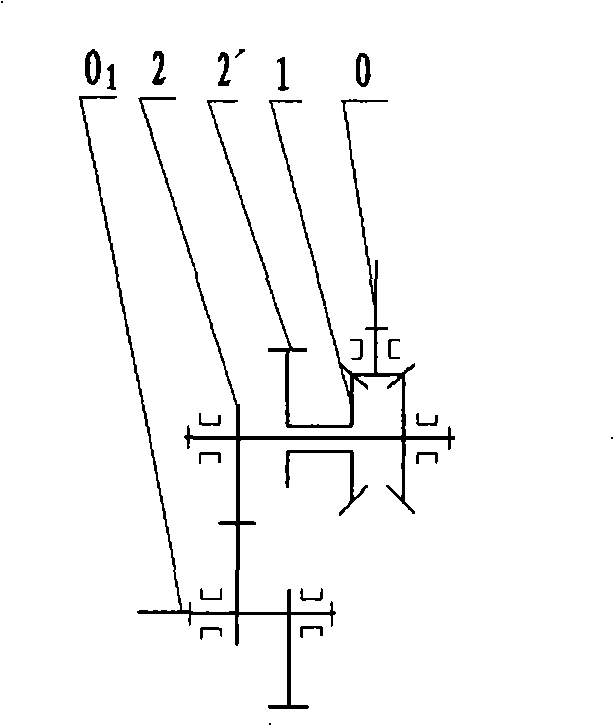

[0061] Figure 1 ~ Figure 3 They are the structural diagrams of three kinds of shaft gear torque converters using single driving shaft, double driving shaft (using the method of shaft outer shaft) and applying bevel gear transmission. As shown in the figure, the shaft gear torque converter consists of n driving shafts axis like 0 1 and 0 2 , crankshaft 0, and 2 total 2n gear trains containing incomplete gears between each driving shaft and the crankshaft, and each driving shaft alternately meshes with two gear trains with the same absolute value of the transmission ratio through the incomplete gears meshing; the ratios of the two gear trains are equal in absolute value. The drive shaft and the crankshaft are respectively the input and output shafts for force-torque conversion; the crankshaft can be selected as any driven shaft in the gear train.

[0062] As can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com