Low tension coil of transformer with split windings

A technology for splitting transformers and low-voltage coils, which is applied to transformer/inductor coils/windings/connections, coil manufacturing, etc. Superior capability, good capacitance distribution, and increased safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

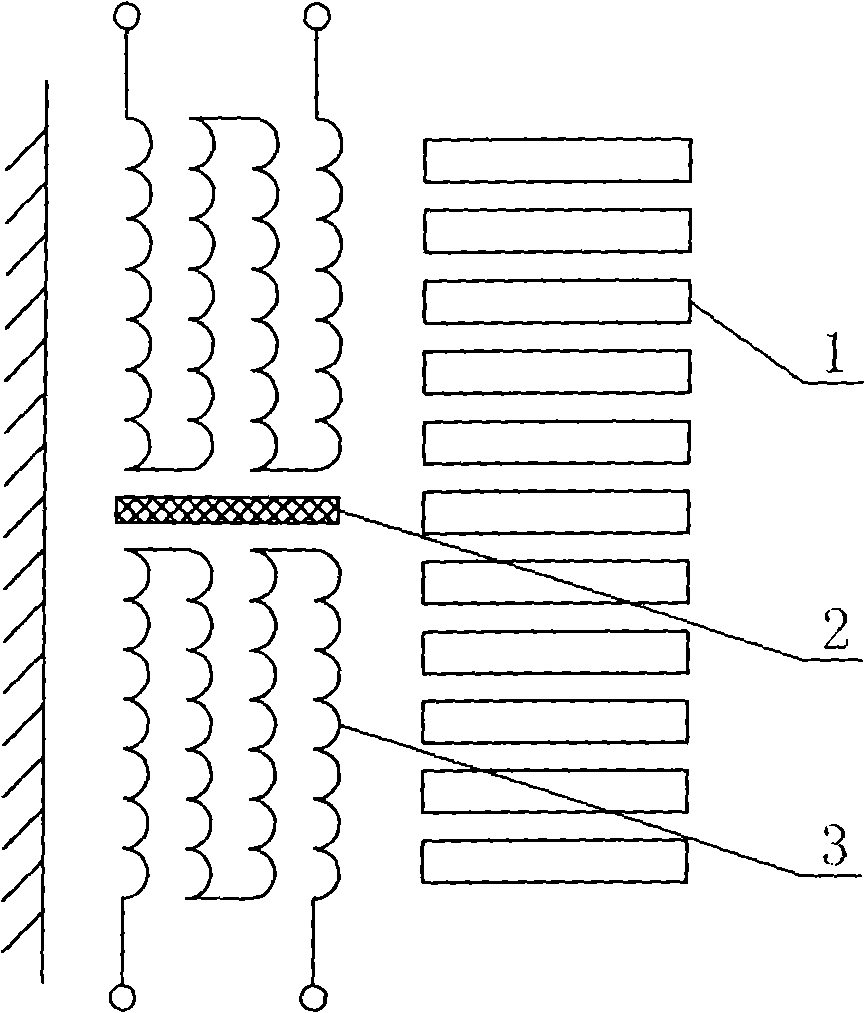

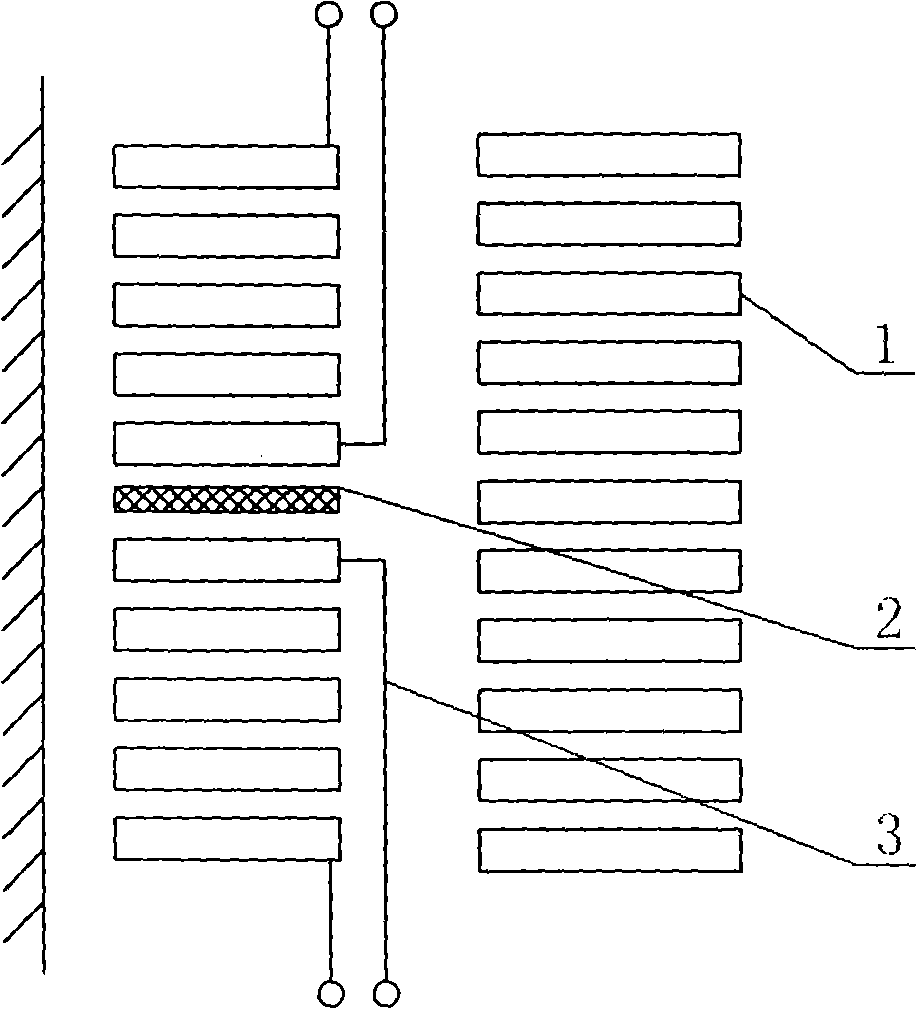

[0009] This specific embodiment has a cylindrical winding structure, and both the head end and the end end of the split transformer lead out from the main flux leakage channel. It is used like figure 2 As shown, there are two low-voltage coils 3 of this specific embodiment arranged side by side on one side of a high-voltage coil 1. The two low-voltage coils 3 are separated by an insulating partition 2. The gap between the two low-voltage coils 3 and the high-voltage coil 1 forms the main drain. In the magnetic air channel, the first ends and the ends of the two low-voltage coils 3 all go out from the outside of the main magnetic leakage air channel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com