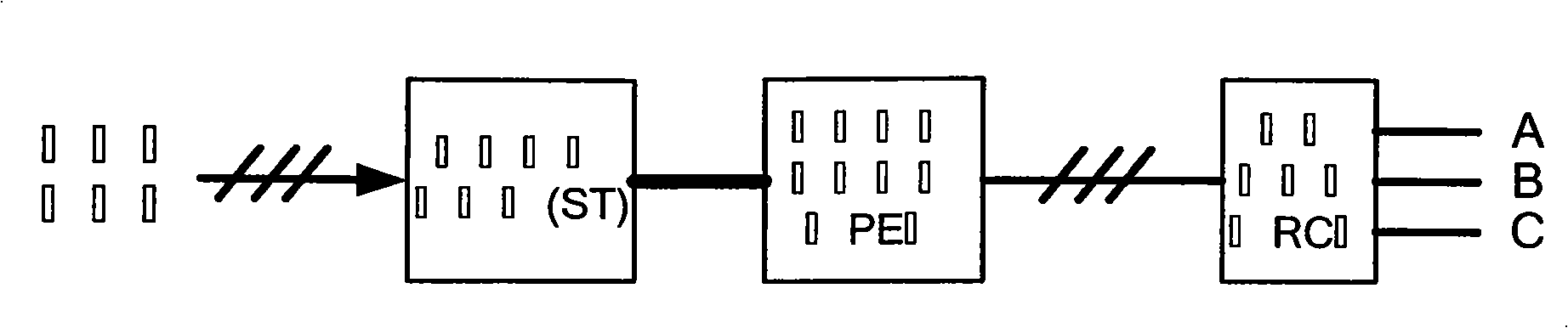

High voltage high power resonant vibration frequency conversion deicing method and its deicing device

A frequency conversion device and high-power technology, which is applied in overhead installation, cable installation, electrical components, etc., can solve the problems of difficult large-scale promotion, long cycle, and increased cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

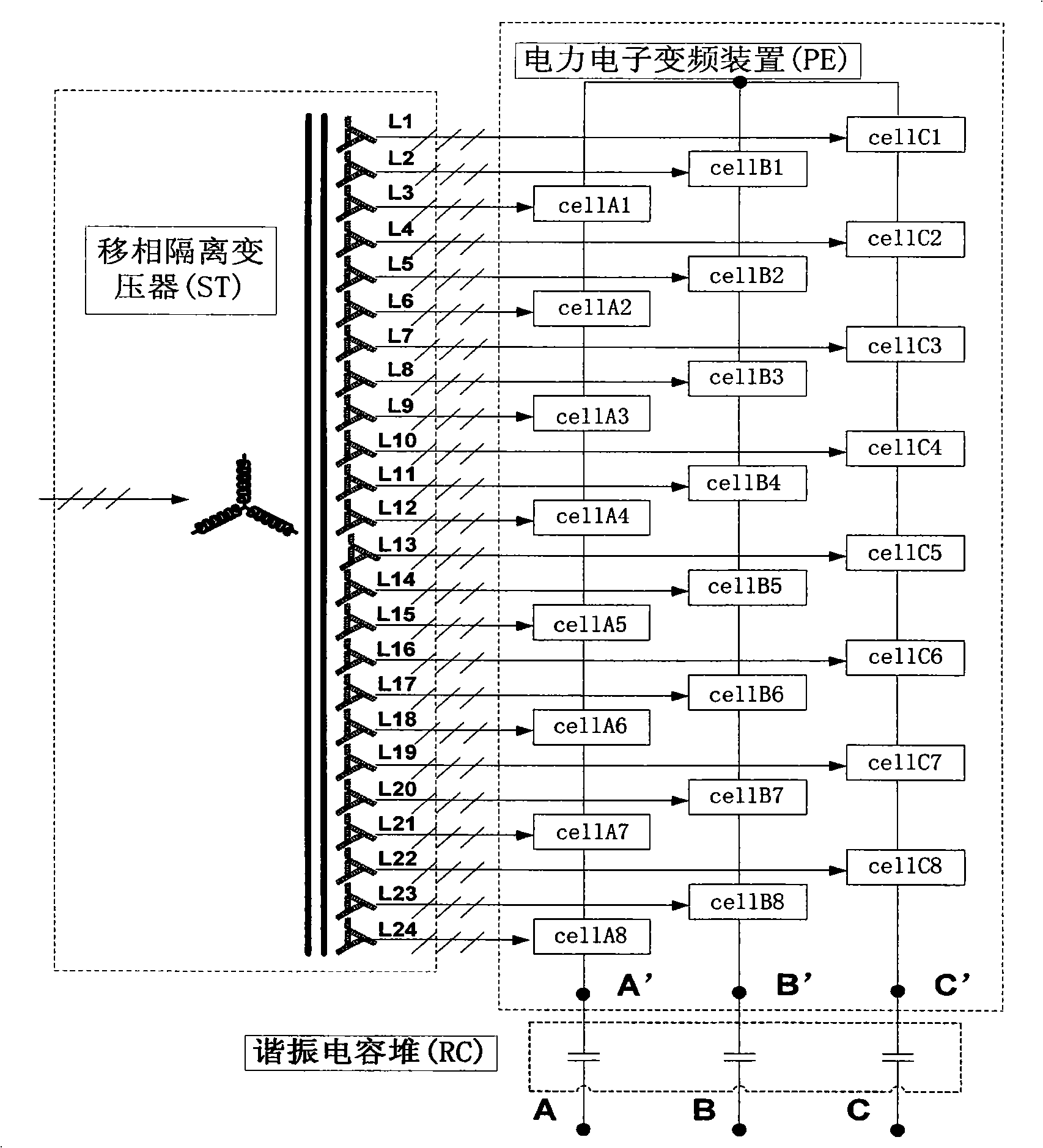

[0064] Three-phase deicing at the same time. Consider the line as a three-phase symmetrical load, such as Image 6 As shown, a high-voltage resonant frequency conversion deicing device is connected to the middle of the 100KM line, and the two 50KM ends are connected by a short wire, and each line is equivalent to two resistive loads. Capacitance value Cap21=Cap22=Cap23 of the three-phase capacitor, frequency f1=f2=f3 of the three-phase power supply. Such a connection form can reduce the influence of the distribution of line parameters. In addition, the simultaneous deicing of three phases can save the time of melting ice and improve the efficiency of melting ice.

no. 2 approach

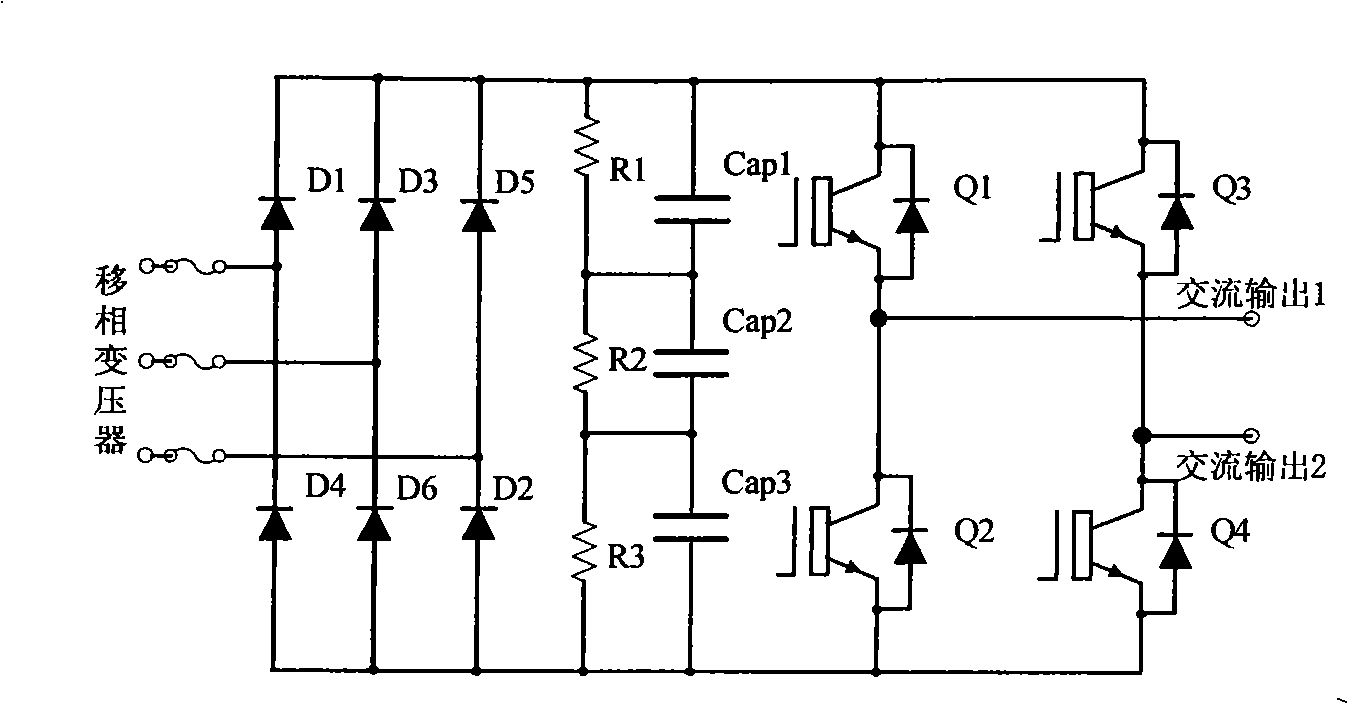

[0066] Single-phase line de-icing. Such as Figure 7 As shown, the power supply end of the deicing device is grounded, the outlet of the resonant capacitor is connected to the middle of the 300KM line, and the deicing power supply device, the ice-coated line, and the earth form a loop. ice. At this time, the internal wiring of the deicing power supply unit is as attached Figure 8 , the equivalent capacitance of three capacitors in series is C ′ ′ = 1 3 C , Depend on f = 1 2 π L ′ C ′ , Available L"=3L; R'=3P 1 / I=3R(f); (wherein L, R(f) are 50km line parameters), the benefit of doing this can make full use ...

no. 3 approach

[0068] Unbalanced phase separation controls ice melting. Used in three-phase asymmetrical lines, it can effectively suppress the unbalance problem between the three phases. Such as Image 6 As shown, the connection mode is the same as that of the first embodiment. The difference is that the three-phase power frequencies f1, f2, and f3 output by the frequency conversion device are not equal, and the capacitance values Cap21, Cap22, and Cap23 of the series resonant capacitors of each phase may also be not equal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com