Waterproof type curling bar and manufacturing method thereof

A production method and heating element technology, which can be applied to curling or perming devices, hair curlers, hairdressing equipment, etc., can solve problems such as explosion or leakage, water resistance and safety cannot be guaranteed, and achieve the goal of improving efficiency and safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The structure, characteristics and purpose of the present invention will be further described below in conjunction with the accompanying drawings.

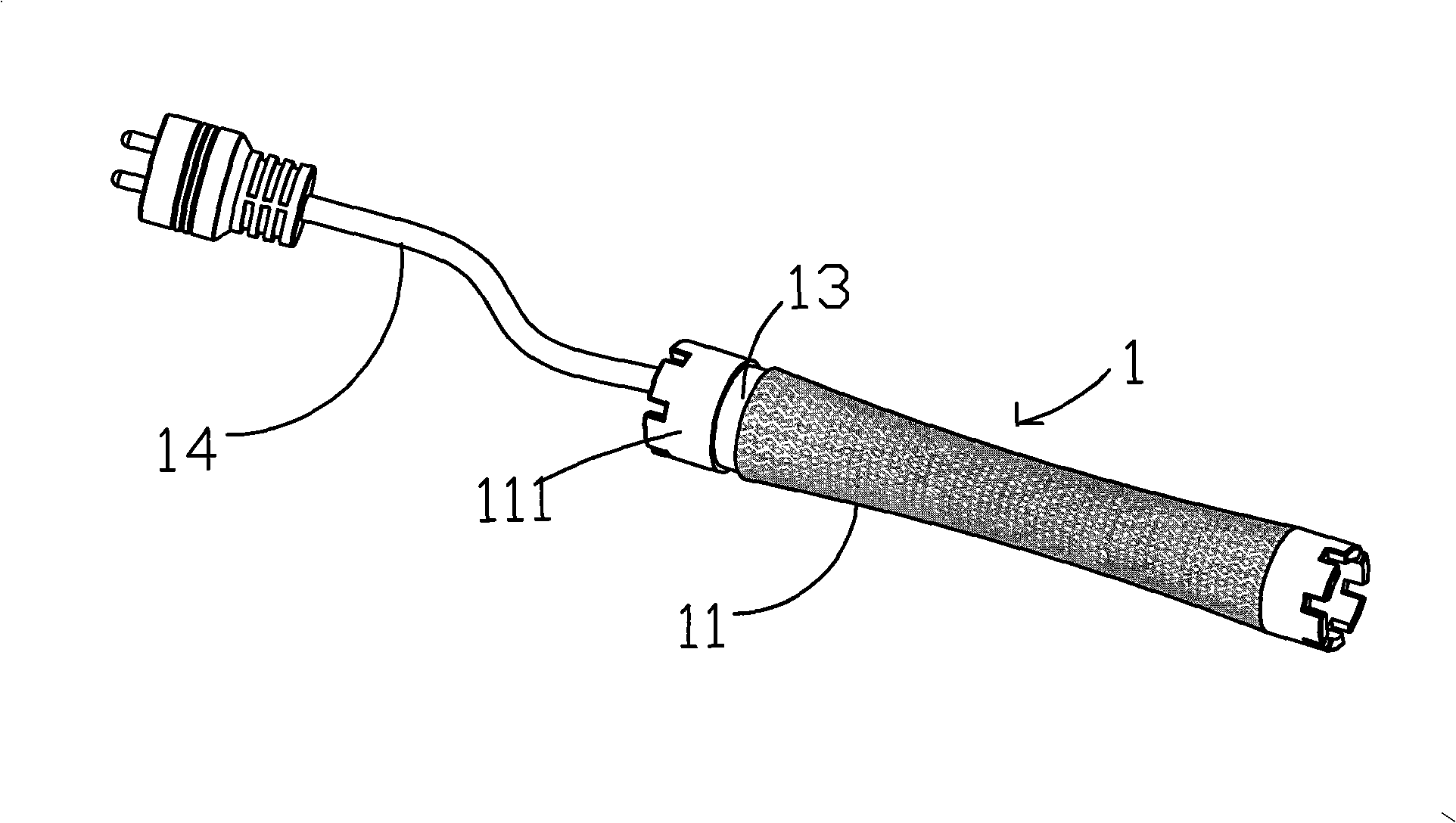

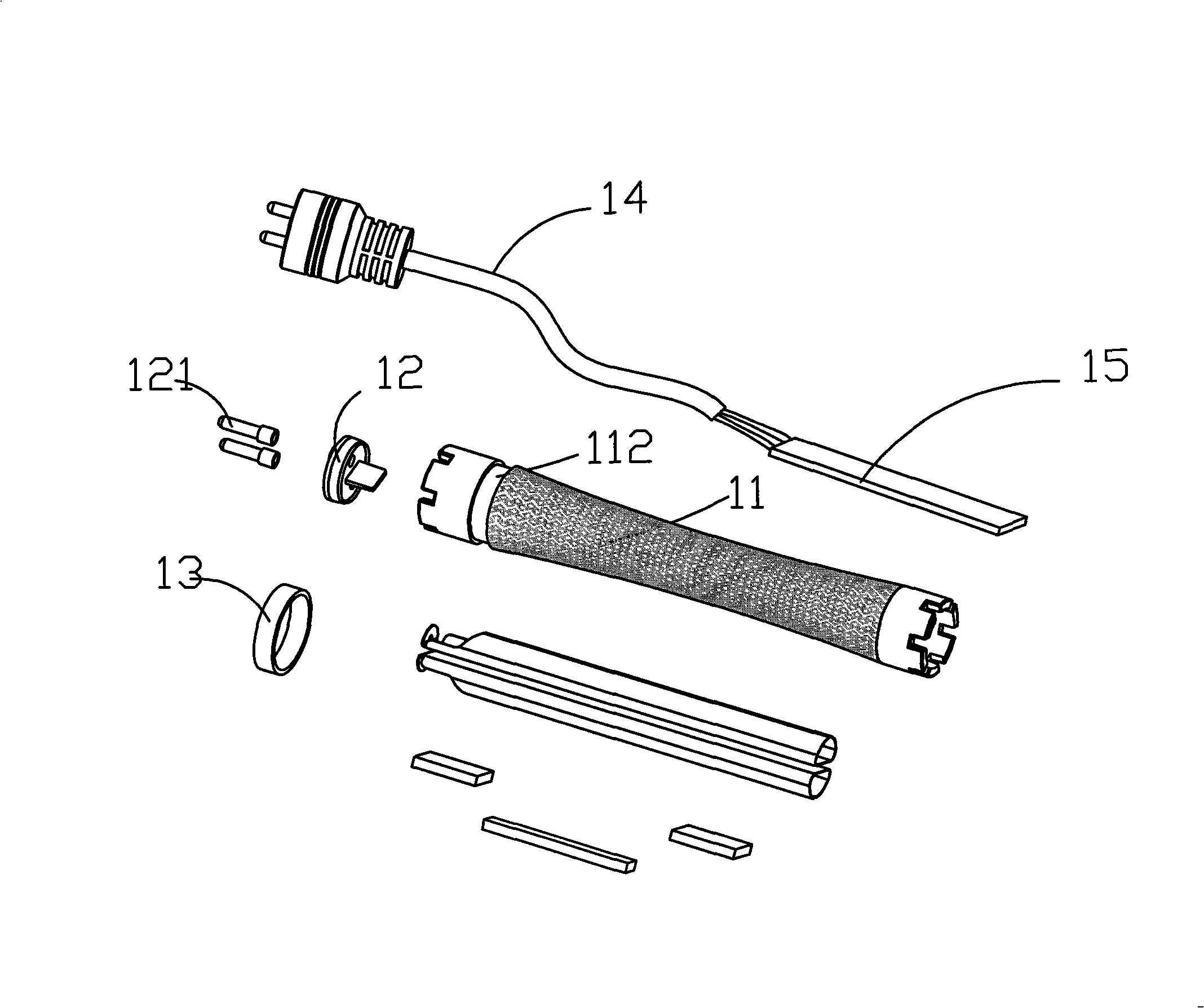

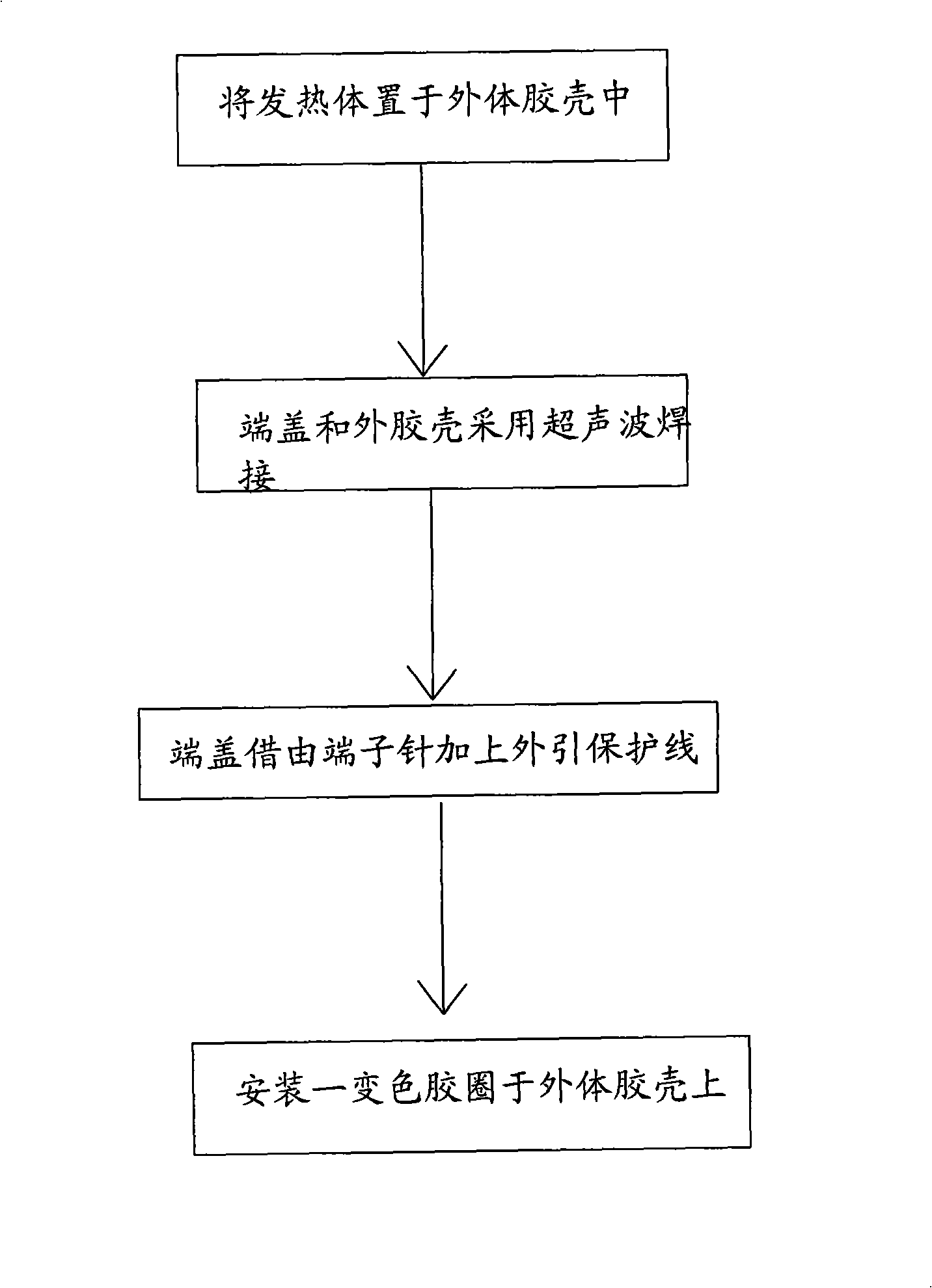

[0015] Such as figure 1 , figure 2 As shown, the waterproof perm bar 1 includes an outer body plastic shell 11, which includes a heating element 15, and a plurality of fixed hair ports 111 with end grooves at both ends; an end cover 12 is fixedly connected to the fixed hair port 111, wherein , the outer body plastic shell 11 includes a circular groove 112 for accommodating a color-changing rubber ring 13, and the color-changing rubber ring 13 can automatically change color according to the physical principle of the temperature of the perm bar to facilitate the judgment of the perm The temperature reached by the bar; the end cover 12 and the outer plastic shell 11 are tightly welded together by ultrasonic waves, and the end cover 12 is extended with an external lead protection wire 14 through the terminal pin 121 to achiev...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap