Endless print belt for rotary stamp

A printing and ring-shaped technology, applied in the field of ring-shaped printing belts for rotating stamps, can solve the problems of lack of rhythm and troublesome operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

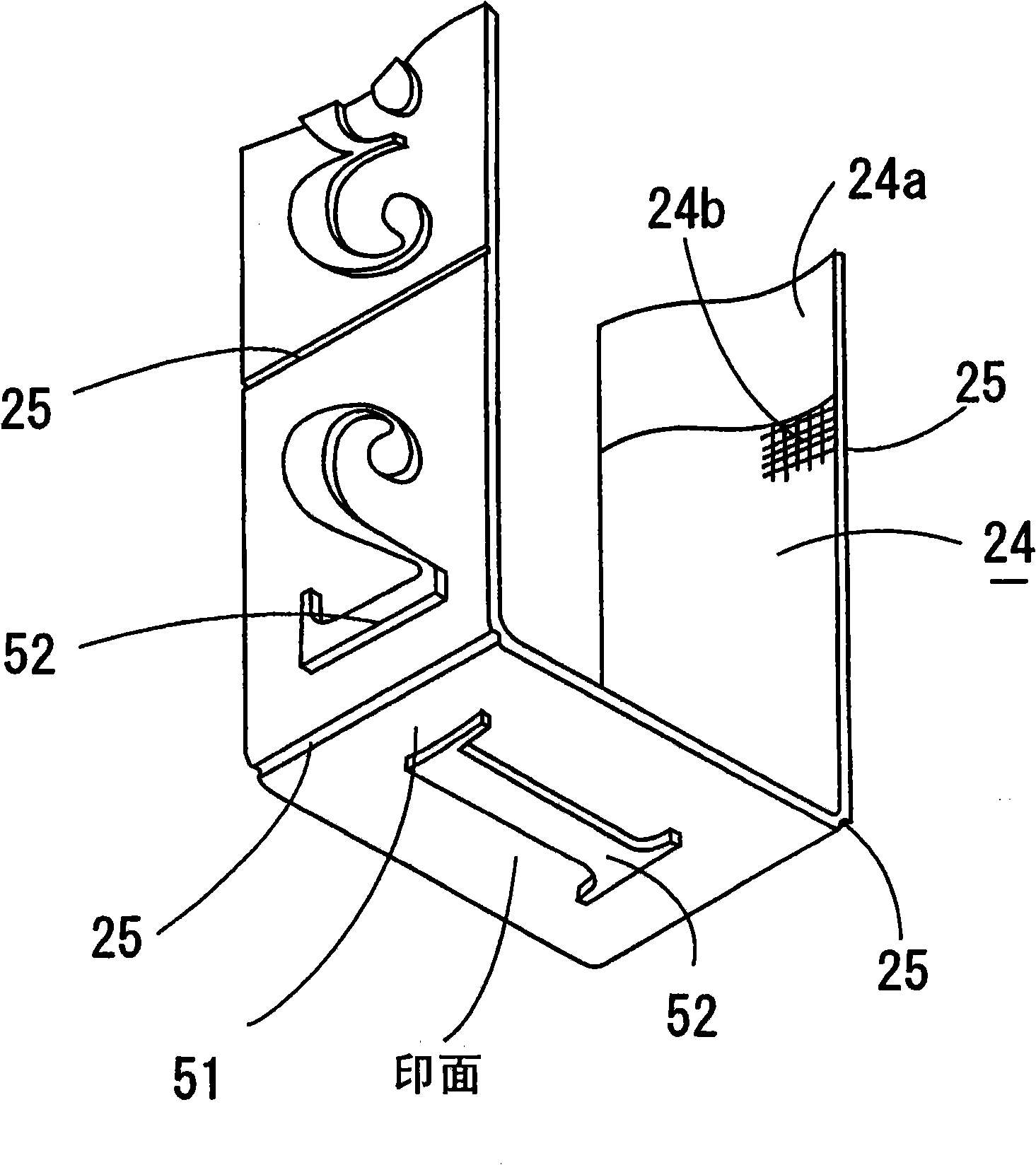

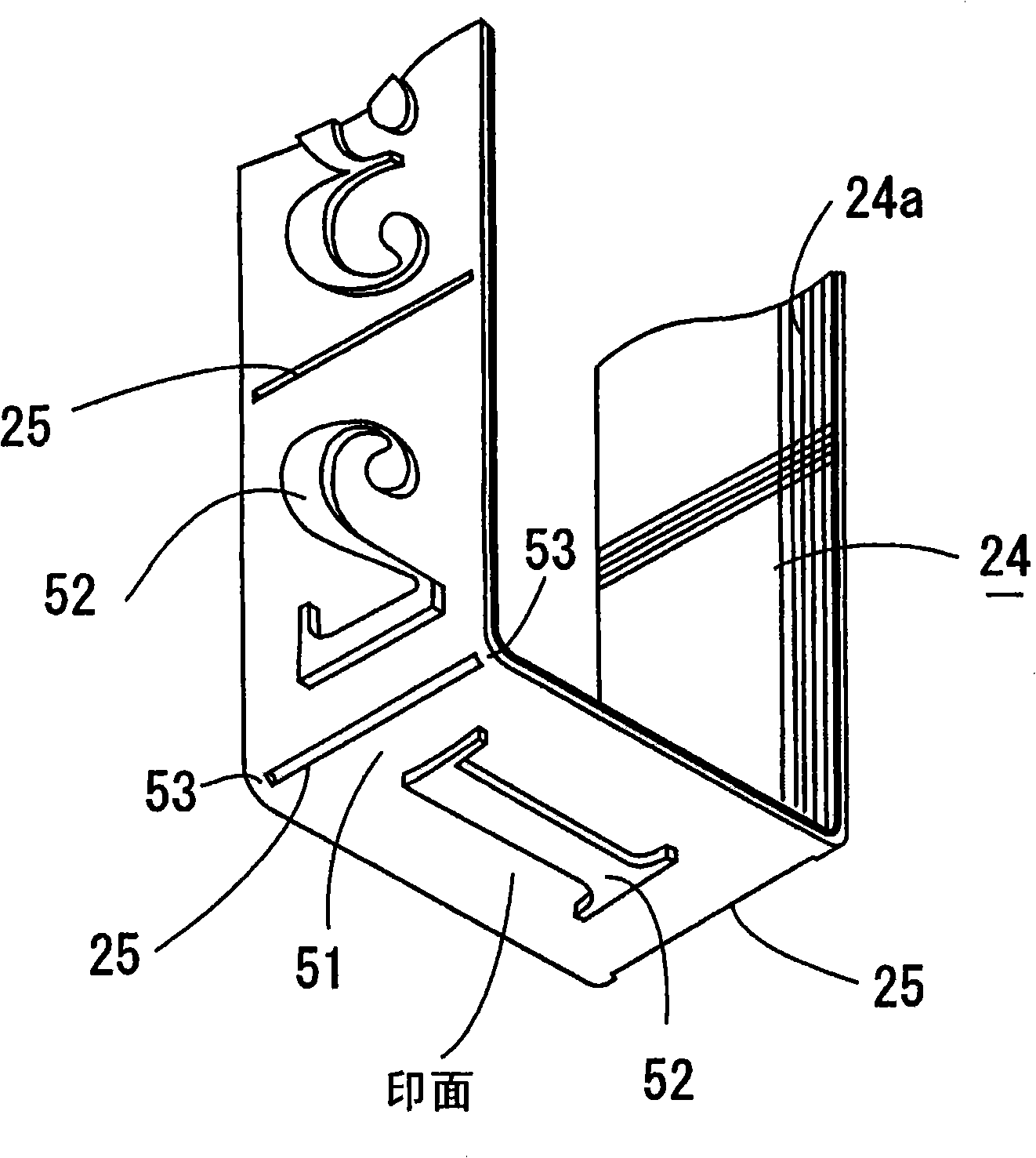

[0015] Next, as a preferred embodiment of the present invention, an endless printing tape for a rotary stamp used for incorporating a rotary stamp in the illustrated rotary stamp with a main stamp will be described.

[0016] exist Figure 4 Among them, 1 is the main body of the rotary stamp with the main stamp, 2 is the rotary stamp, and 3 is the main stamp containing the rotary stamp 2, which is rotatably supported in the middle of the rotary stamp frame erected on the rotary stamp 2. Between the plurality of rotating parts 22 on 21 and the bridge portion 23 erected at the lower end of the rotating stamp frame, the endless printing tape for rotating stamps of the present invention is suspended.

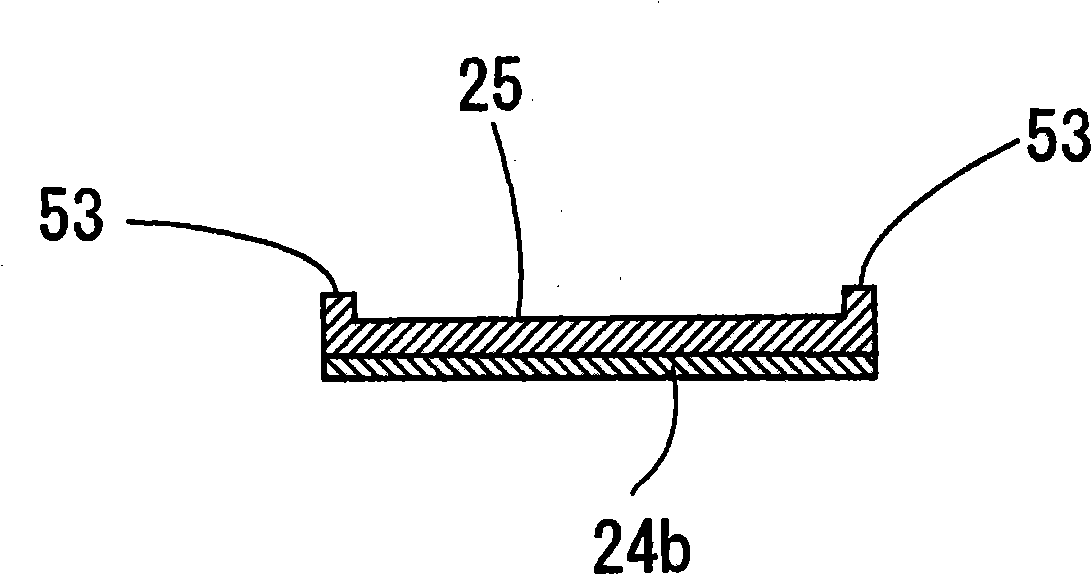

[0017] The printing tape main body 24 of the endless printing tape for rotary stamps of the present invention is as follows: figure 1 and figure 2 As shown, a porous thermoplastic resin tape substrate 24a having countless continuous pores such as foamed polyethylene resin is used ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap