Integral loop metal flexible pipe and assembling method thereof

A metal hose, integrated technology, applied in the direction of hose connection device, hose, pipe, etc., can solve the problems of unsatisfactory hose joint connection, short service life of metal hose, unsuitable for mass production, etc. The effect of low cost, high production efficiency and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

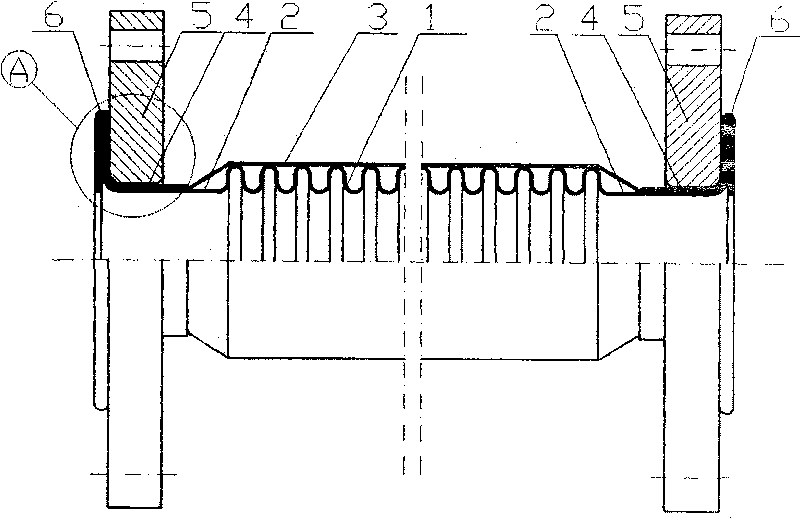

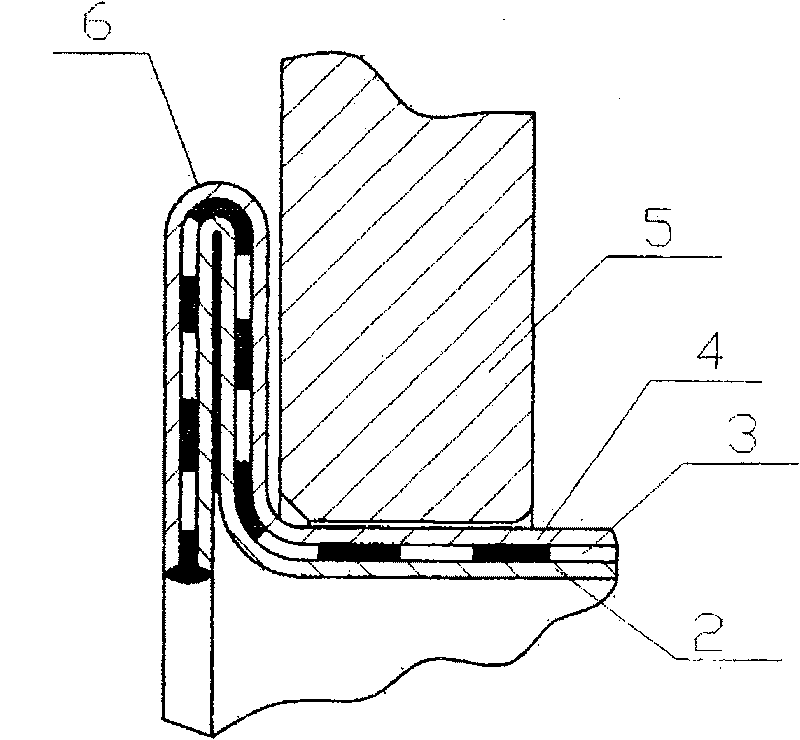

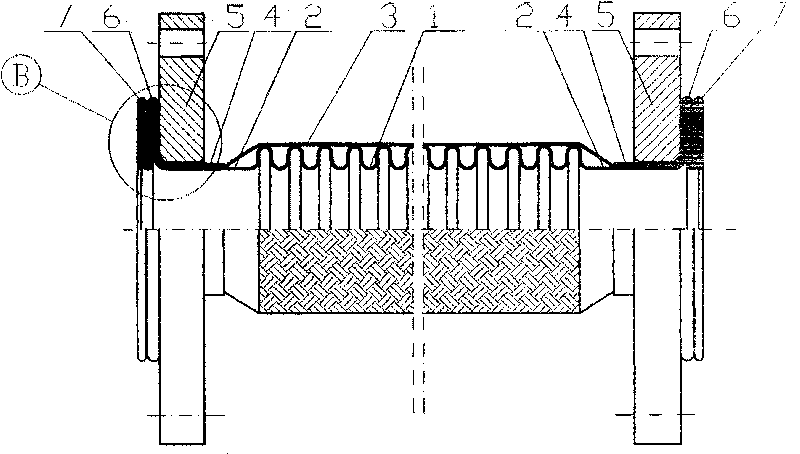

[0018] The specific implementation of the present invention is described as follows. Such as Figure 1 to Figure 4 As shown, the structure of the single flange 6 and the double flange 7 of the integrated looper metal hose is roughly the same. 5 composition. The metal mesh sleeve 3 is set on the outer diameter of the bellows 1 and the straight pipe 2, and the metal mesh sleeve 3 is between the straight pipe 2 and the metal retaining ring 4. A single flanging and a double flanging are arranged respectively, penetrate into the metal joint, and are respectively arranged on one side of the metal joint. Both the single flanging and the double flanging are formed into a corrugated shape by internal expansion forming equipment, and then axially pressed to complete an integral flange sealing surface that is closely connected. The two ends of the one-piece loop metal hose have the same structure, except that the flanging structure is slightly different, and they are all matched with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com