Heating control method of electric water heater

An electric water heater, heating control technology, applied in the direction of electrical program control, fluid heaters, lighting and heating equipment, etc., can solve the problem of power interruption, etc., to achieve the effect of energy saving and continuous heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

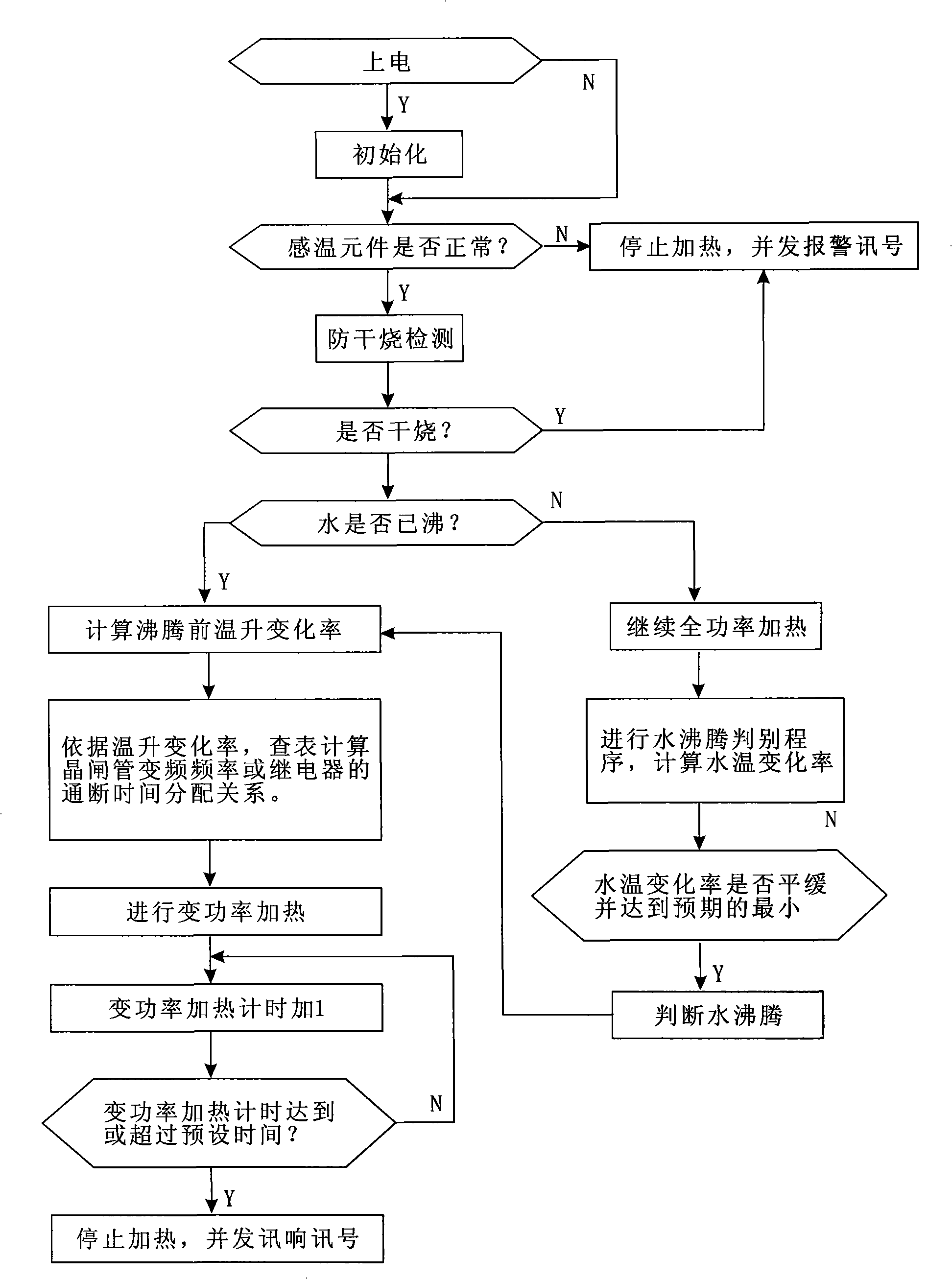

Image

Examples

Embodiment 1

[0023] Embodiment 1, for a medium-power electric water heater, 2000w, a thermistor NTc with a negative temperature coefficient is set in the electric water heater, the microprocessor CPU has multiple A / D conversions, and the control circuit is a transistor connected to the output port of the microprocessor , turn on the power, the sensor detects the temperature related to the water temperature in the electric water heater in real time, and when its temperature is greater than the initial temperature of the calculated temperature change by 60°C, it starts to calculate the temperature change rate, and stores the temperature and the calculated temperature change rate, cycle Set to 8 seconds, the microprocessor calculates the water temperature change rate: it represents the A / D conversion digital quantity related to the water temperature in the first 8 seconds at that time as the subtrahend, and represents the current A / D conversion digital quantity related to the water temperature ...

Embodiment 2

[0024] Example 2, the water temperature change rate before boiling is 2 degrees / second, if the full power is still 2000W, then the average power to keep the boiling state after boiling is 500W, if 8 seconds is a cycle, then turn on for 2 seconds and turn off for 6 seconds Achieving an average power of 500W. The control circuit switches the heating power and continues heating until the specified time, the program returns to the initial state, and the rate of change and intermediate calculation results are cleared.

Embodiment 3

[0025] Embodiment 3, for the electric water heater whose water temperature rises slowly, the power is relatively small, which is 1600w, the thermistor NTC with negative temperature coefficient is set in the electric water heater, the microprocessor CPU has multiple A / D conversion, and the control circuit is a microprocessor The transistor connected to the output port of the water heater is turned on, and the sensor detects the temperature of the water in the electric water heater in real time. When the temperature is greater than the initial temperature of 55°C for calculating the temperature change rate, the temperature change rate is calculated, and the temperature and the calculated temperature are stored. Temperature change rate, the period is set to 8 seconds, the microprocessor calculates the water temperature change rate: the digital quantity representing the water temperature in the first 8 seconds is the subtrahend, the digital quantity representing the current water te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com