Parameterization static state ultra-unit structuring method

A construction method and a technology of superunits, which are applied in electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as long calculation time, heavy workload, and difficult optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

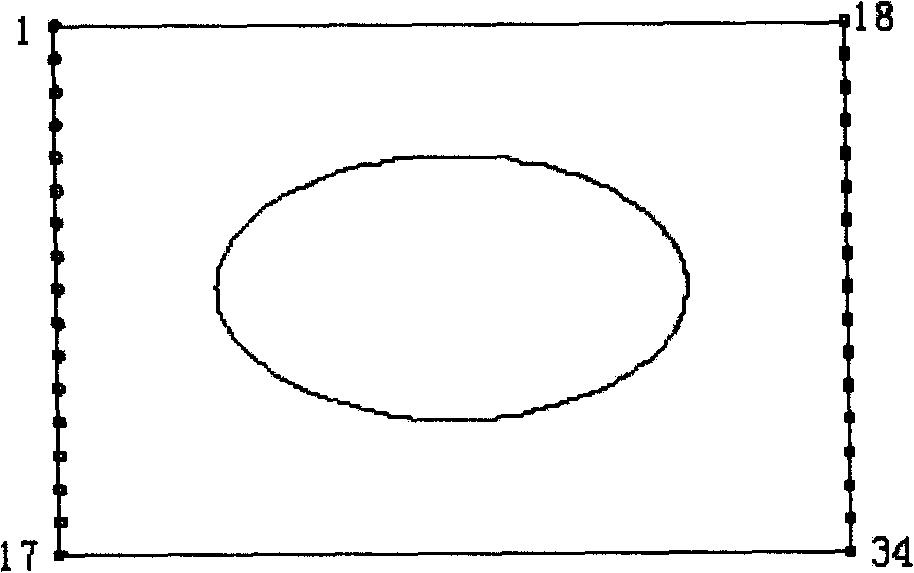

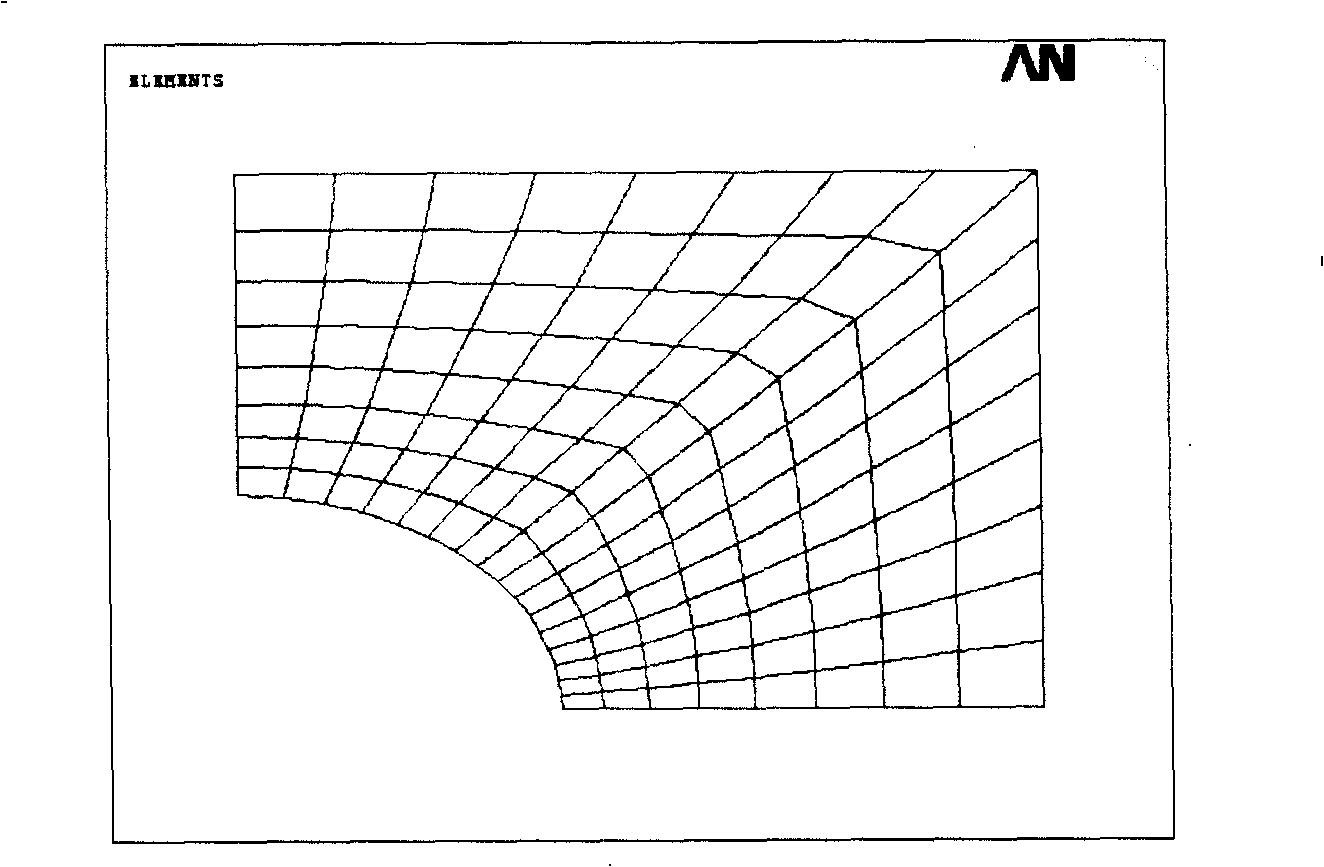

[0100] 1 superunit structure

[0101] Determine the basic size of the superelement as 0.3×0.2m; the long radius of the central opening is r1=0.07m, the short radius is r2=0.03m, and the solid182 unit is used; material properties: elastic modulus E=2e11Pa, Poisson’s ratio Pr = 0.3. Create a finite element model such as Figure 7 As shown, the total rigid point number of the superelement is as follows Figure 8 As shown, the single rigid point number of the central hole of the superelement is as follows Figure 11 shown. Nodes 1 to 17 are fully constrained, nodes 18 to 23 are loaded with a load of 800N in the x direction, nodes 24 to 34 are loaded with a load of 1000N in the x direction, and nodes 18 to 34 are loaded with a load of 1000N in the y direction.

Embodiment 2

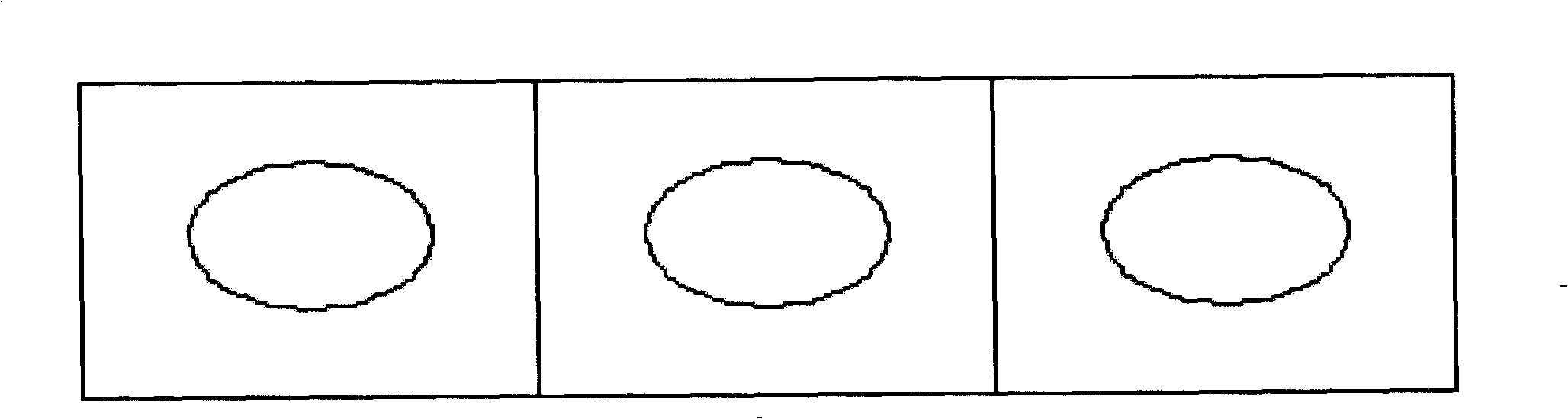

[0103] 3 consecutive superunit structures

[0104] Adopt solid182 unit. Material properties: modulus of elasticity E=2e11Pa, Poisson's ratio Pr=0.3.

[0105] Central elliptical hole radius from left to right:

[0106] The first unit r1=0.06m, r2=0.04m;

[0107] The second unit r1=0.07m, r2=0.05m;

[0108] The third unit r1=0.10m, r2=0.06m.

[0109] Finite element models such as Figure 9 As shown, the overall total rigid point number is as follows Figure 10 As shown, the single rigid point number of the central hole of the superelement is as follows Figure 11 As shown, nodes 1 to 17 are fully constrained, nodes 52 to 60 apply a load of 800N in the x direction, nodes 61 to 68 apply a load of 1000N in the x direction, nodes 52 to 60 apply a load of 800N in the y direction, and nodes 61 to 68 Apply a load of 1000N in the y direction.

[0110] ANSYS calculation results and superelement calculation results such as Figure 12 , Figure 13, Figure 14.

[0111] It can be se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com