Device for examining workpieces

A workpiece and inspection point technology, which is applied in the field of inspecting workpieces, especially circuit board devices, can solve problems such as the inability to obtain tool position information, and achieve high-precision results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

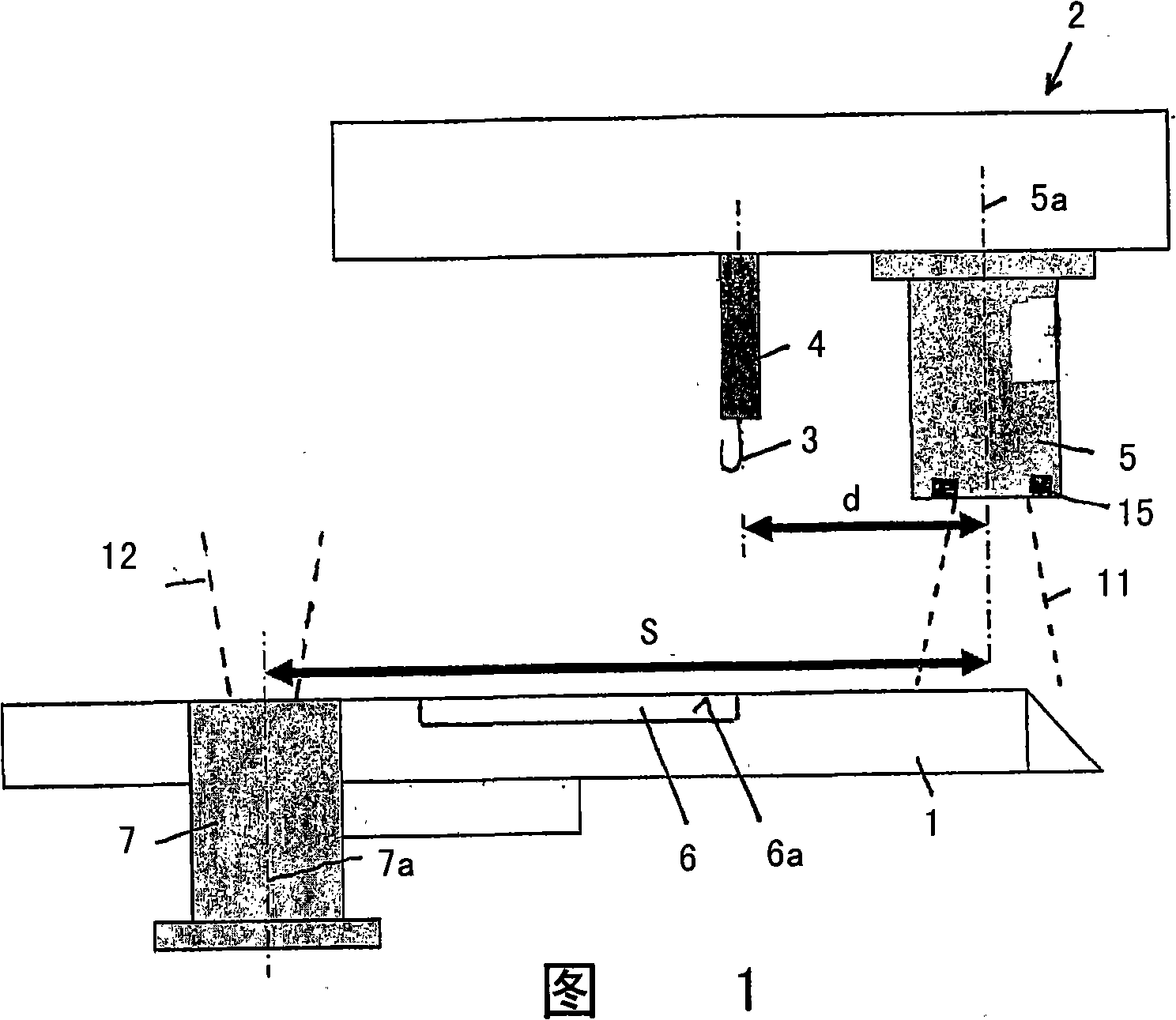

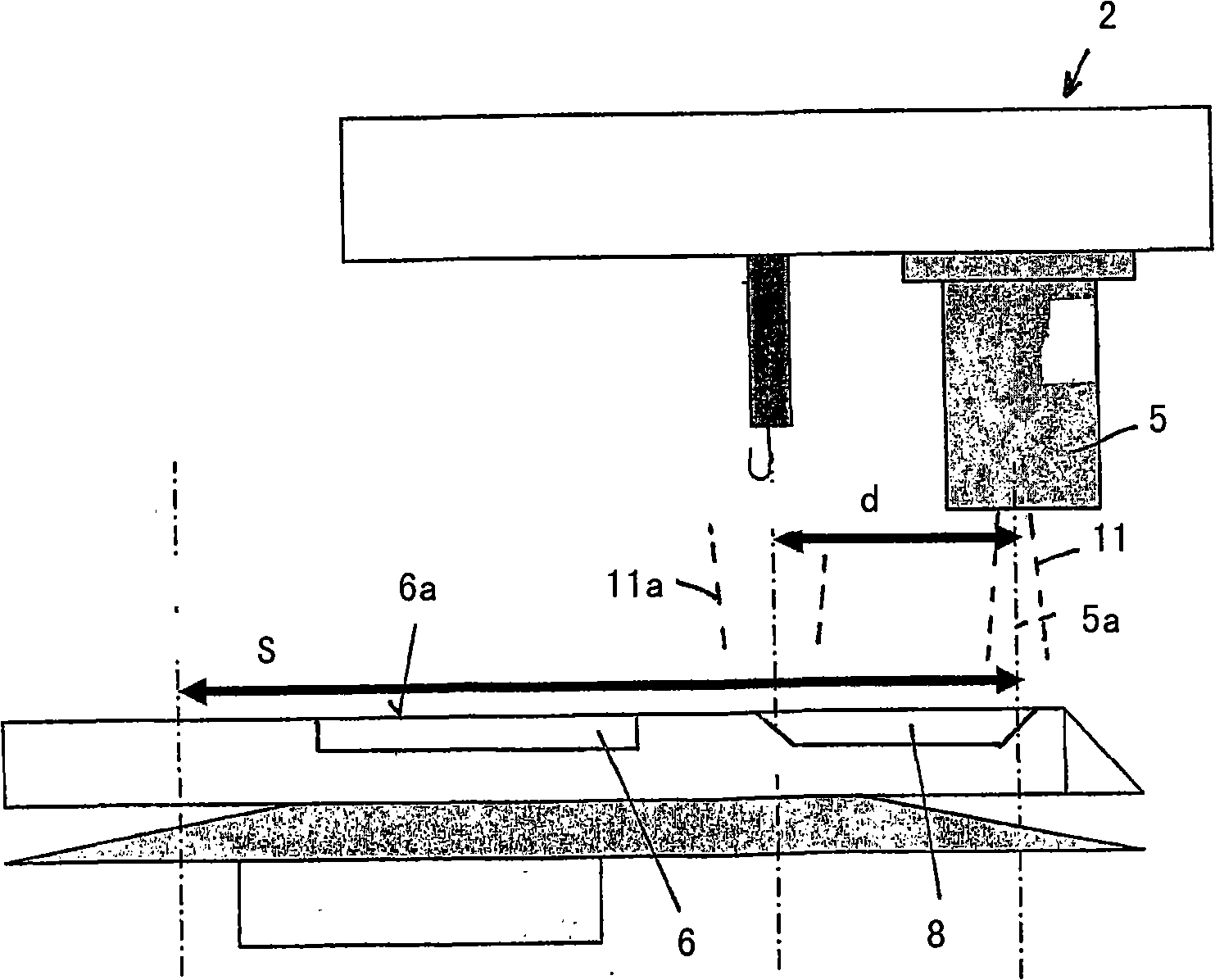

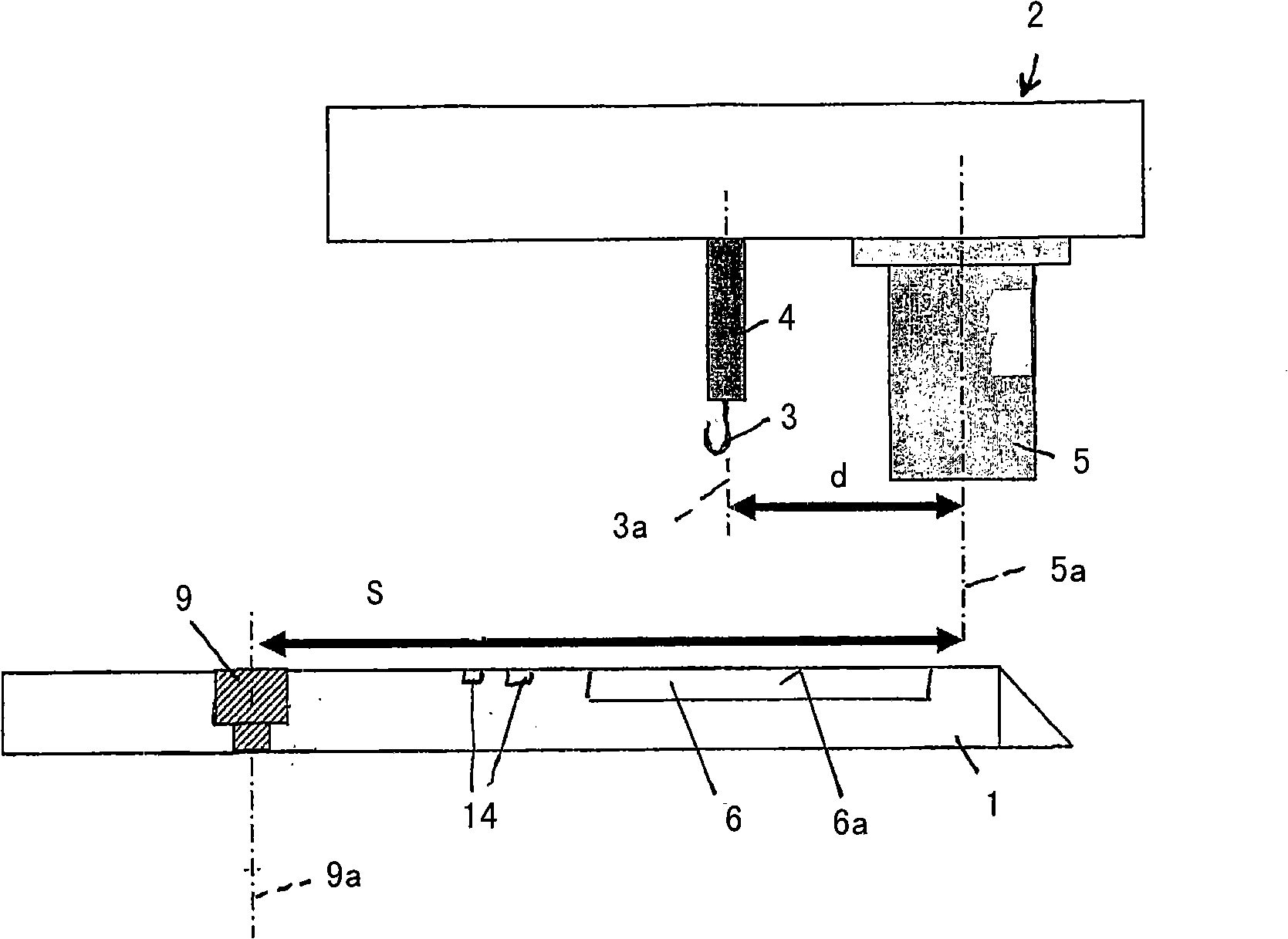

[0027] The device from FIG. 1 comprises a seat 1 for a workpiece 6 on which the measurement is carried out and which is arranged in a workpiece plane 6 a. A tool 3 in the form of a hook is suspended in the measuring head 2 via a tension detection device 4 . Furthermore, the detection range of the camera 5 , which is fixed to the measuring head 2 , is indicated with reference numeral 11 . The mechanical offset d is defined as the distance of the axis 5 a of the camera 5 from the tool 3 . In the socket 5 is fixed a further camera 7 with an upwardly pointing detection cone 12 into which the tool 3 and reference points 15 can be introduced, which are attached to the camera 5 and thus to the to measuring head 2.

[0028] The calibration process can now be carried out in such a way that the movement of the measuring head 2 first causes the tool 3 to be oriented towards the optical axis 7 a of the other camera 7 before the axis 5 a of the camera 5 is aligned with the axis 7 a by me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com