An assembly machine for the seal ring of the inner shaft of the dresser on the numerical control machine tool

A technology of CNC machine tools and sealing rings, which is applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of missing sealing rings on shafts, small diameters of shafts, and affecting product quality, so as to reduce product rework and improve product quality. Product quality, the effect of reducing manual output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

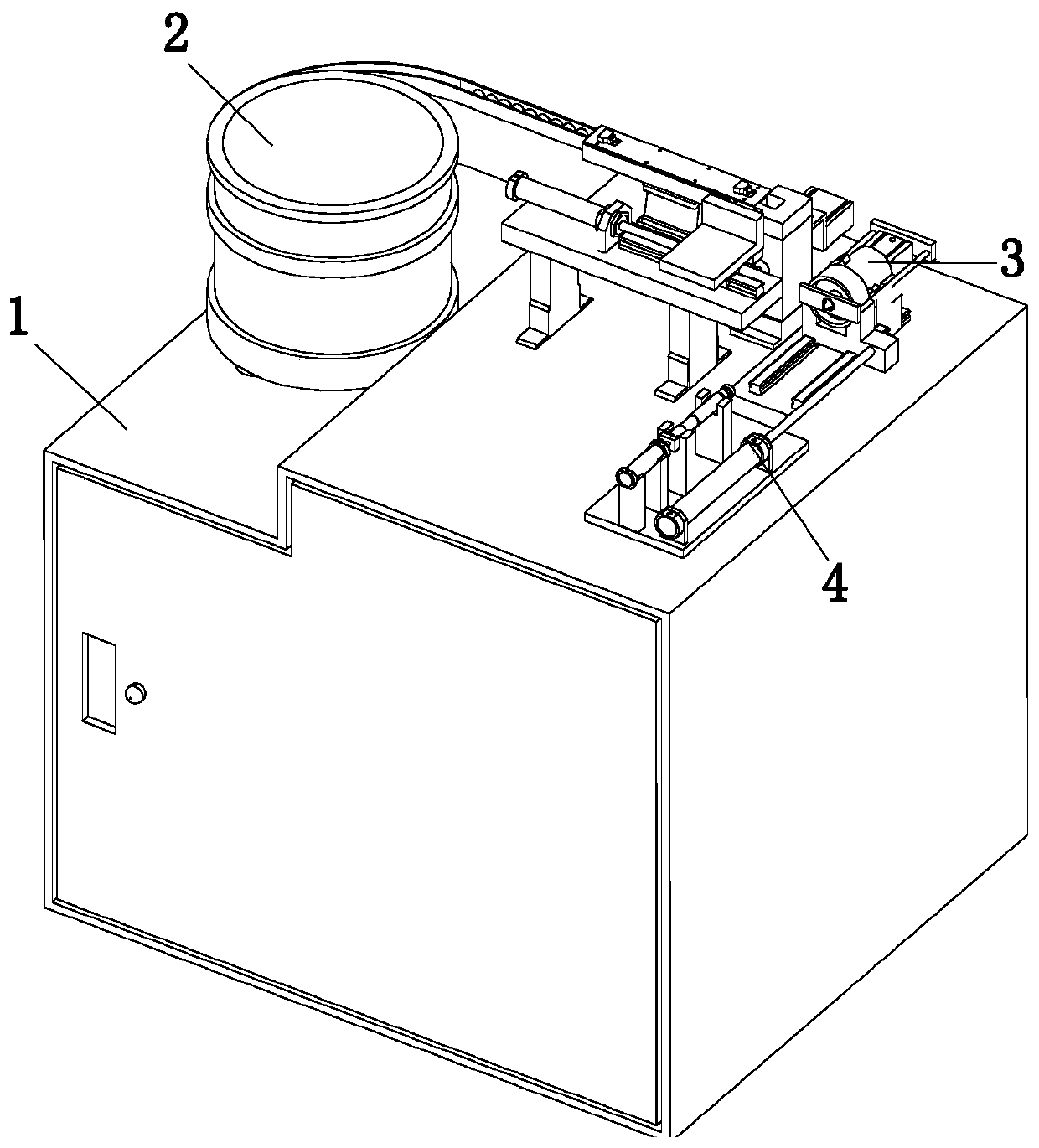

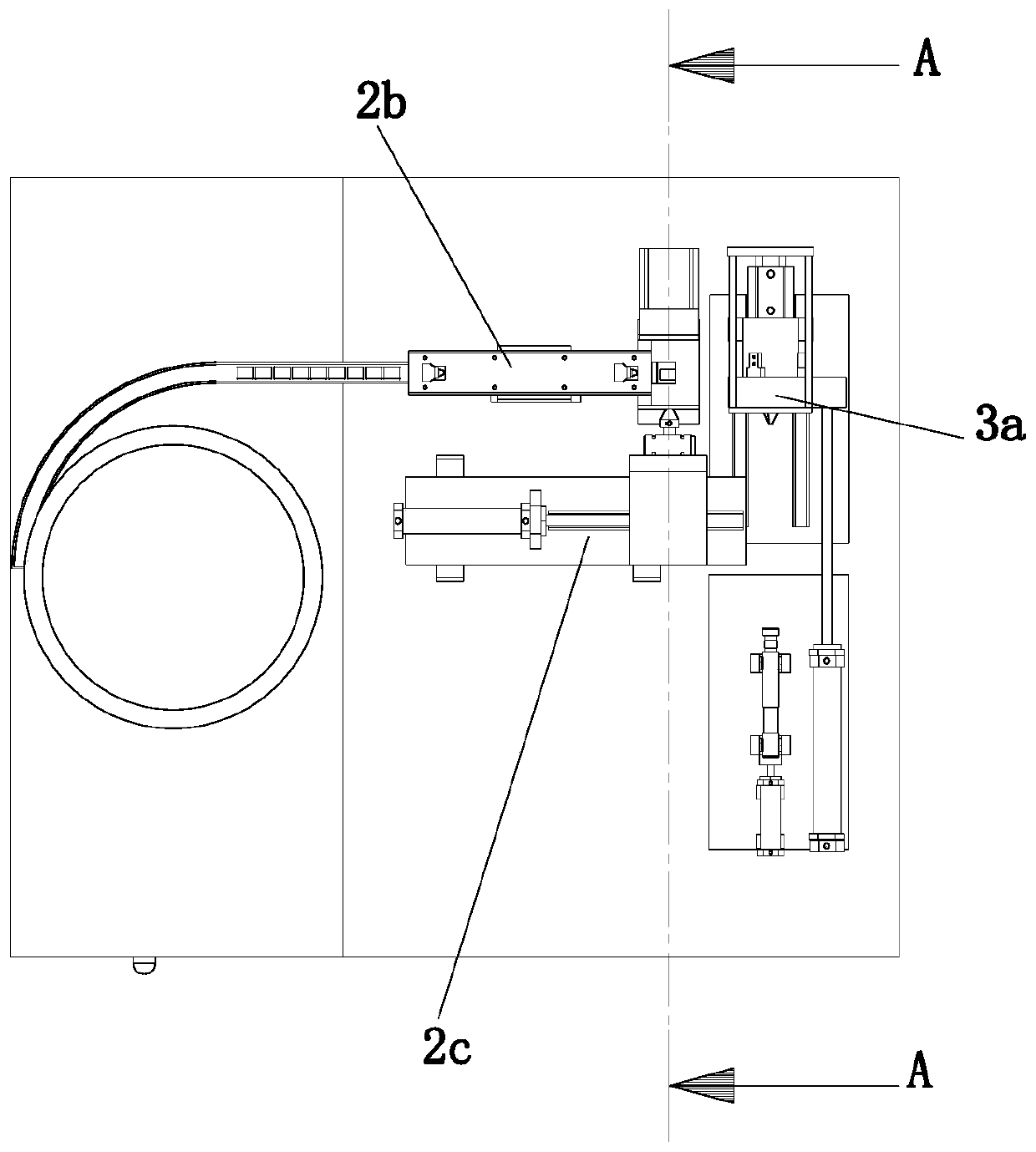

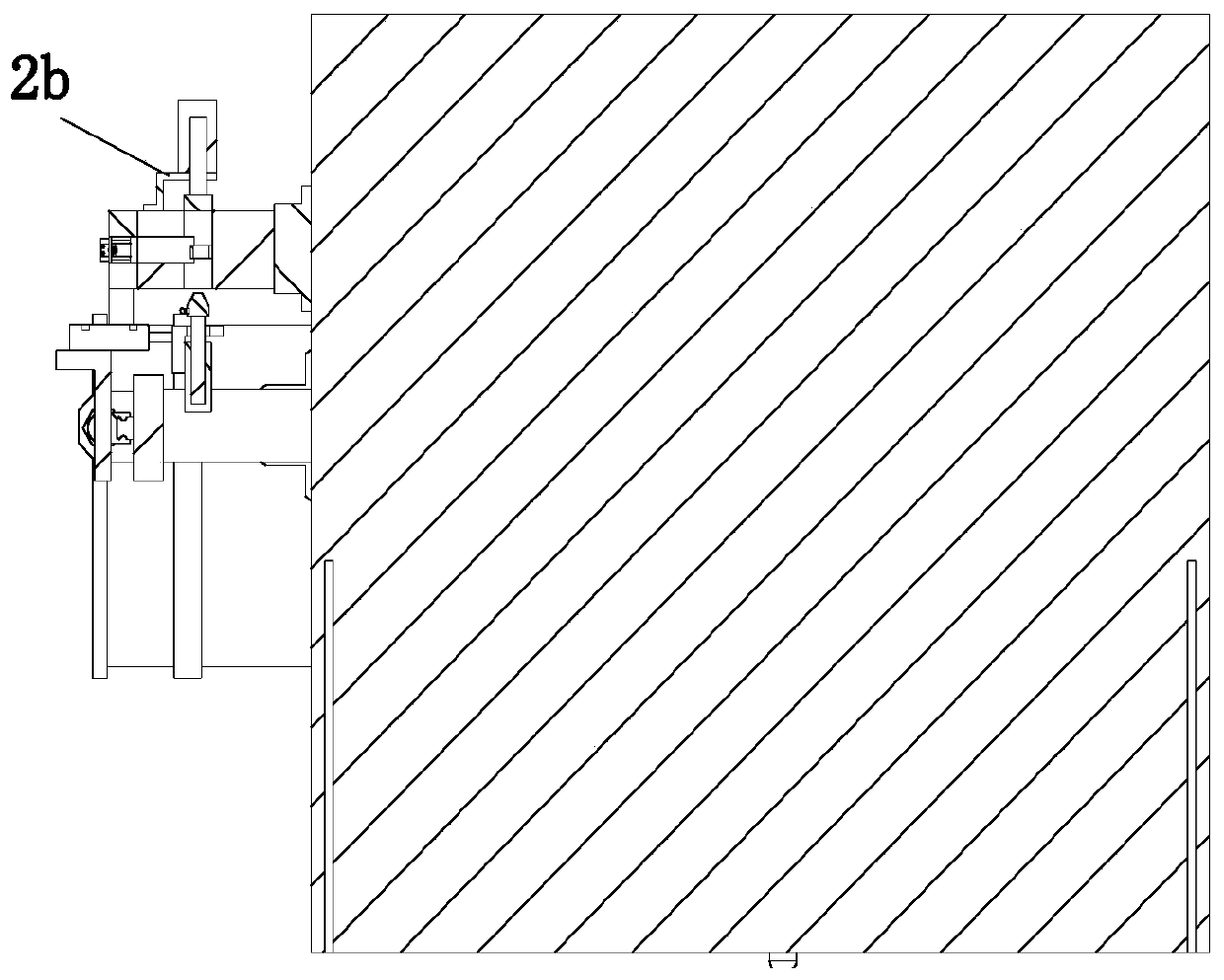

[0030] refer to Figure 1 to Figure 12The shown assembly machine for the seal ring of the inner shaft of the dresser on the CNC machine tool includes a work cabinet 1 and a seal ring feeding device installed on the top of the work cabinet 1 for intermittently feeding several seal rings to be clamped 2. The sealing ring positioning device 3 installed at the output end of the sealing ring feeding device 2 for positioning a single sealing ring to be assembled and the sealing ring positioning device 3 installed on the top of the working cabinet 1 and located at the output end of the sealing ring positioning device 3 for the assembly to be assembled Shaft positioning device 4 for limiting the position of the shaft, the sealing ring feeding device 2 includes a vibrating feeding tray 2a, and a seal for neatly arranging sev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com