Assembling method of sealing ring of shaft rod in finisher on numerical control lathe

A technology of numerical control machine tools and assembly methods, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems affecting product quality, missing seal rings on shafts, small shaft diameters, etc., and improve the success rate of suction , Improve assembly work and improve installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments of the specification: The present invention relates to a method for assembling the sealing ring of the inner shaft of the trimmer on a CNC machine tool, which is specifically realized by using a sealing ring assembly machine.

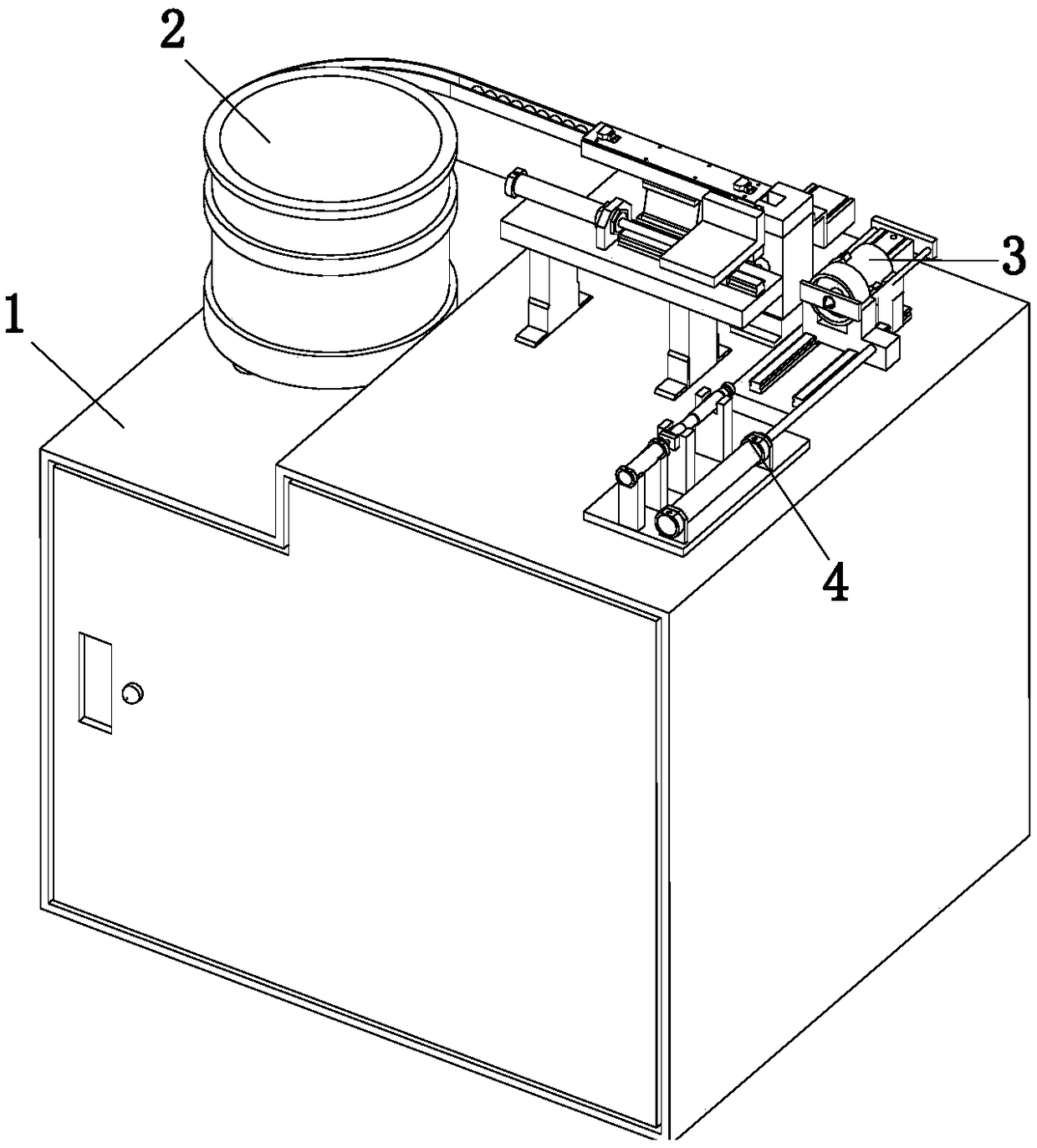

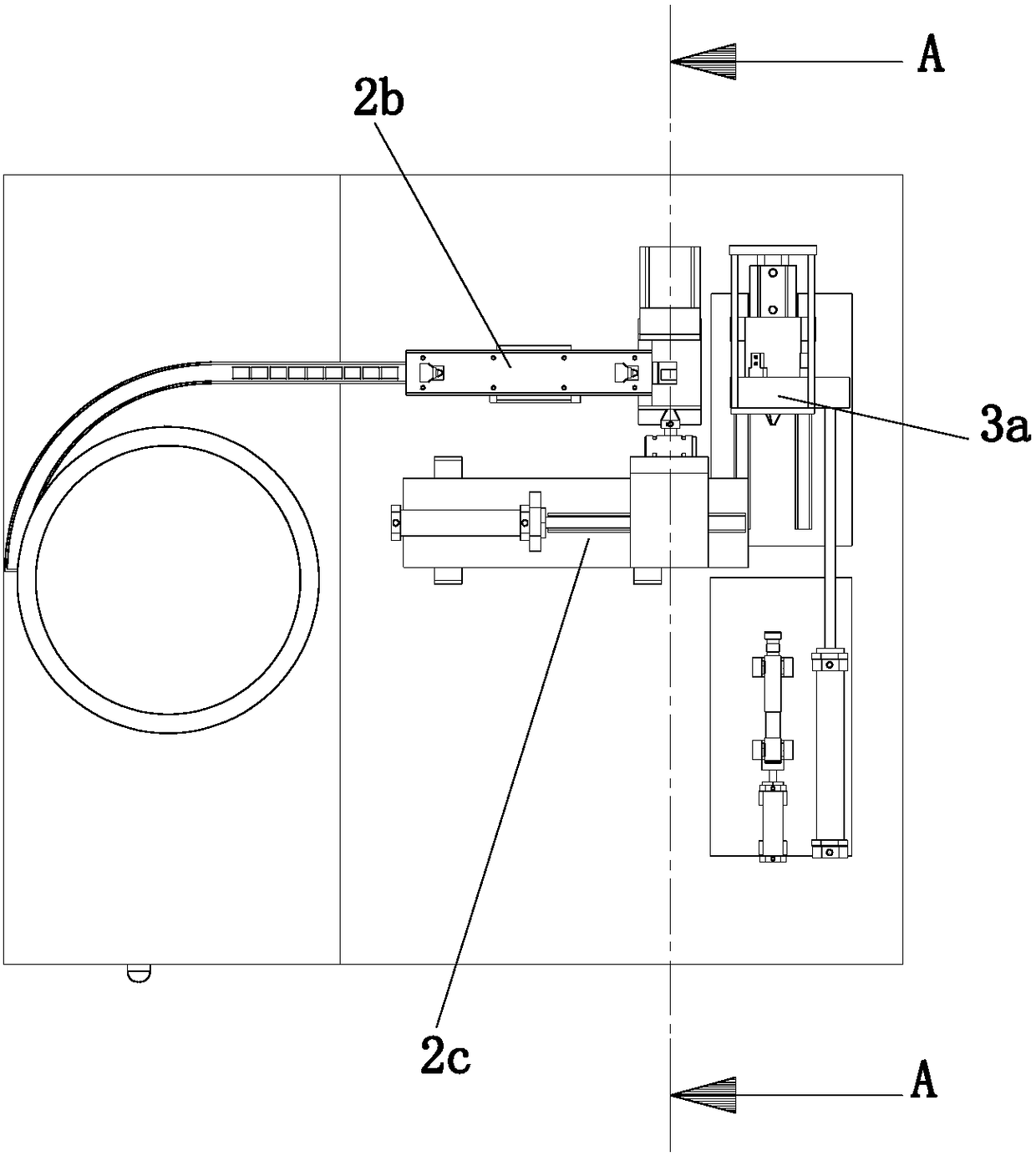

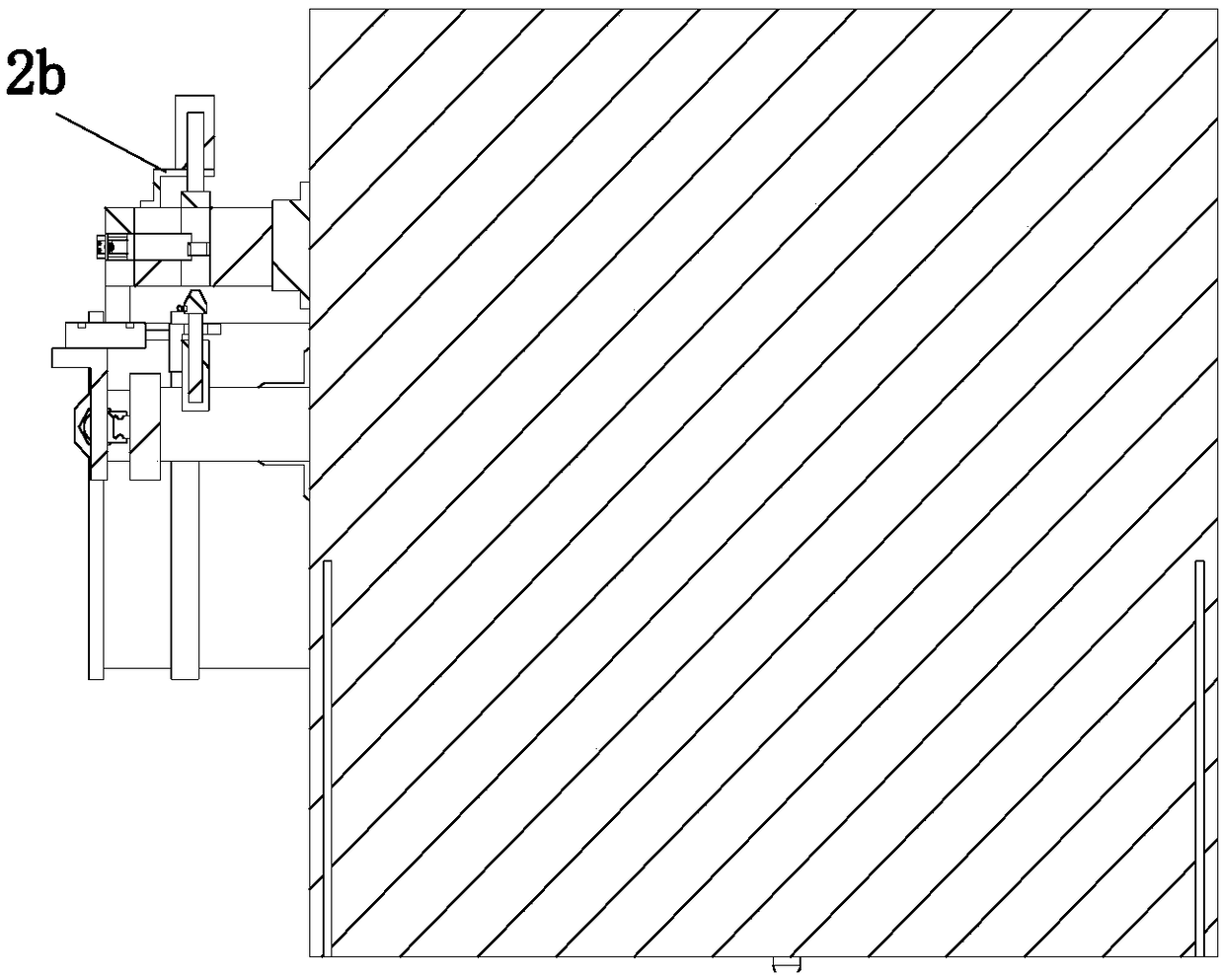

[0035] refer to Figure 1 to Figure 12 The sealing ring assembly machine shown includes a working cabinet 1, a sealing ring feeding device 2 installed on the top of the working cabinet 1 for intermittent feeding of several sealing rings to be clamped, and a sealing ring feeding device 2 installed at the output end of the sealing ring feeding device 2 A sealing ring positioning device 3 for positioning a single sealing ring to be assembled and a shaft positioning device 4 installed on the top of the working cabinet 1 and located at the output end of the sealing ring positioning device 3 for limiti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com