Process for preparing wide-band and wave-absorbing magnetic multilayer membranous

A broadband, magnetic film technology, applied in the field of preparing broadband absorbing layers, can solve problems such as multilayer films that have not been disclosed, and achieve excellent high-frequency absorption characteristics and the effect of a simple and easy method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following are examples of the present invention.

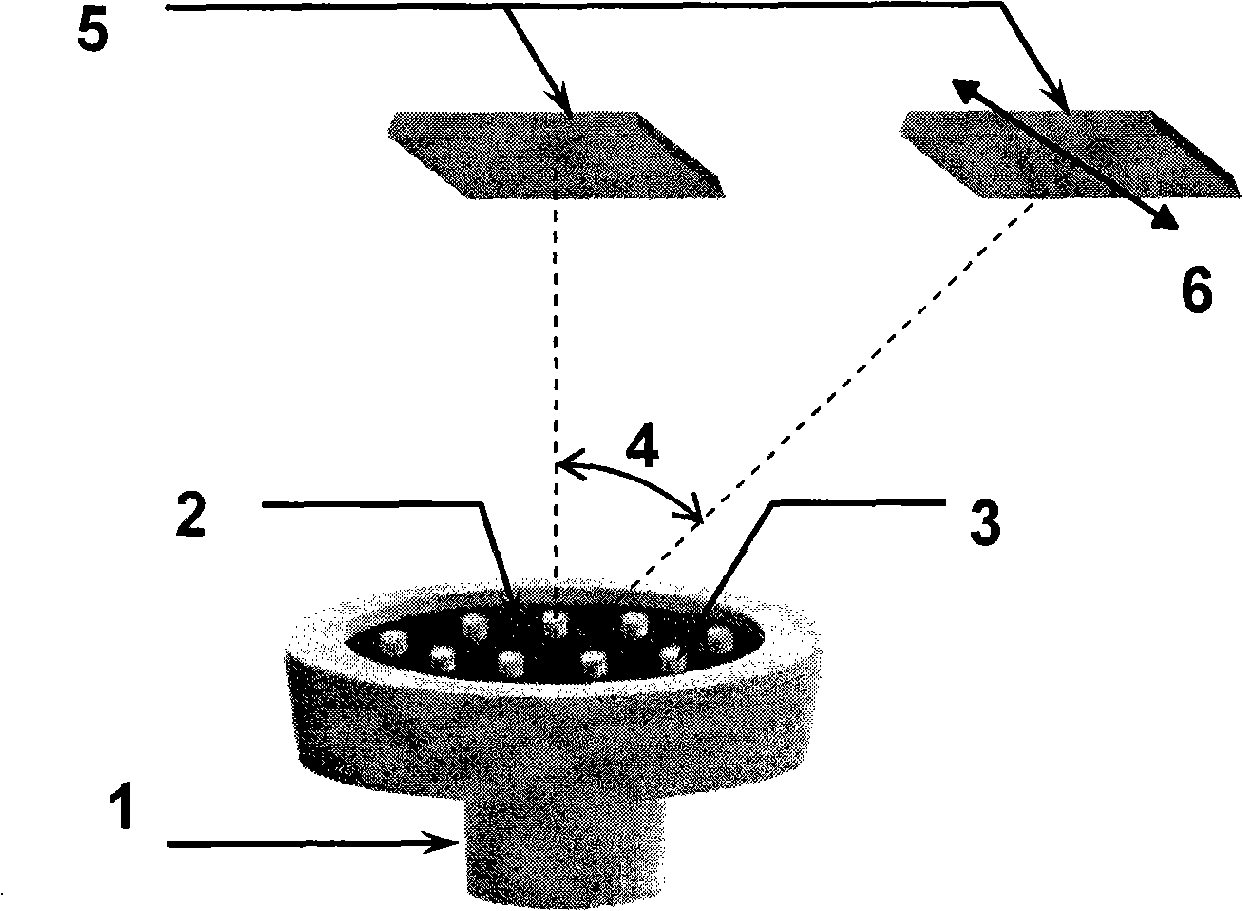

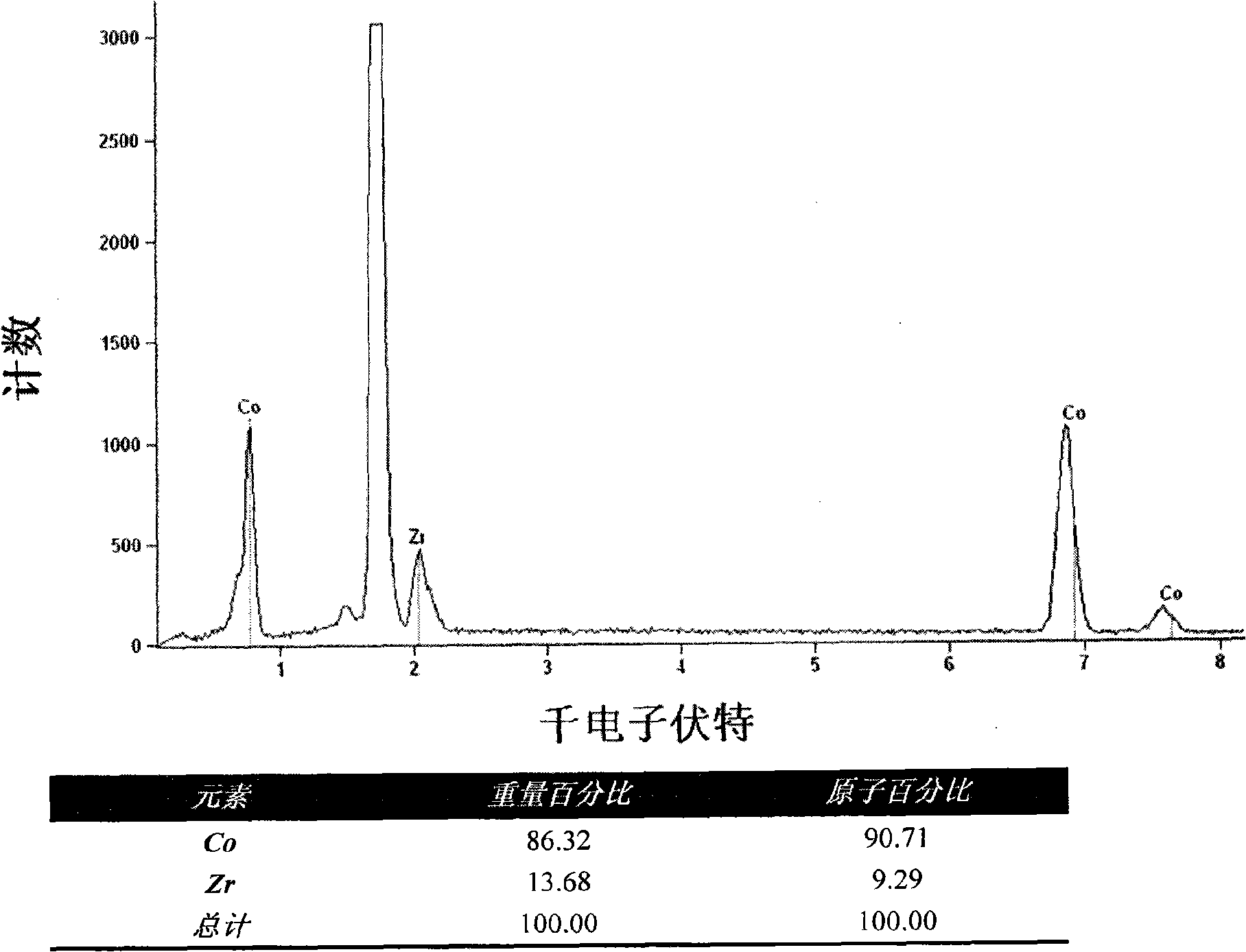

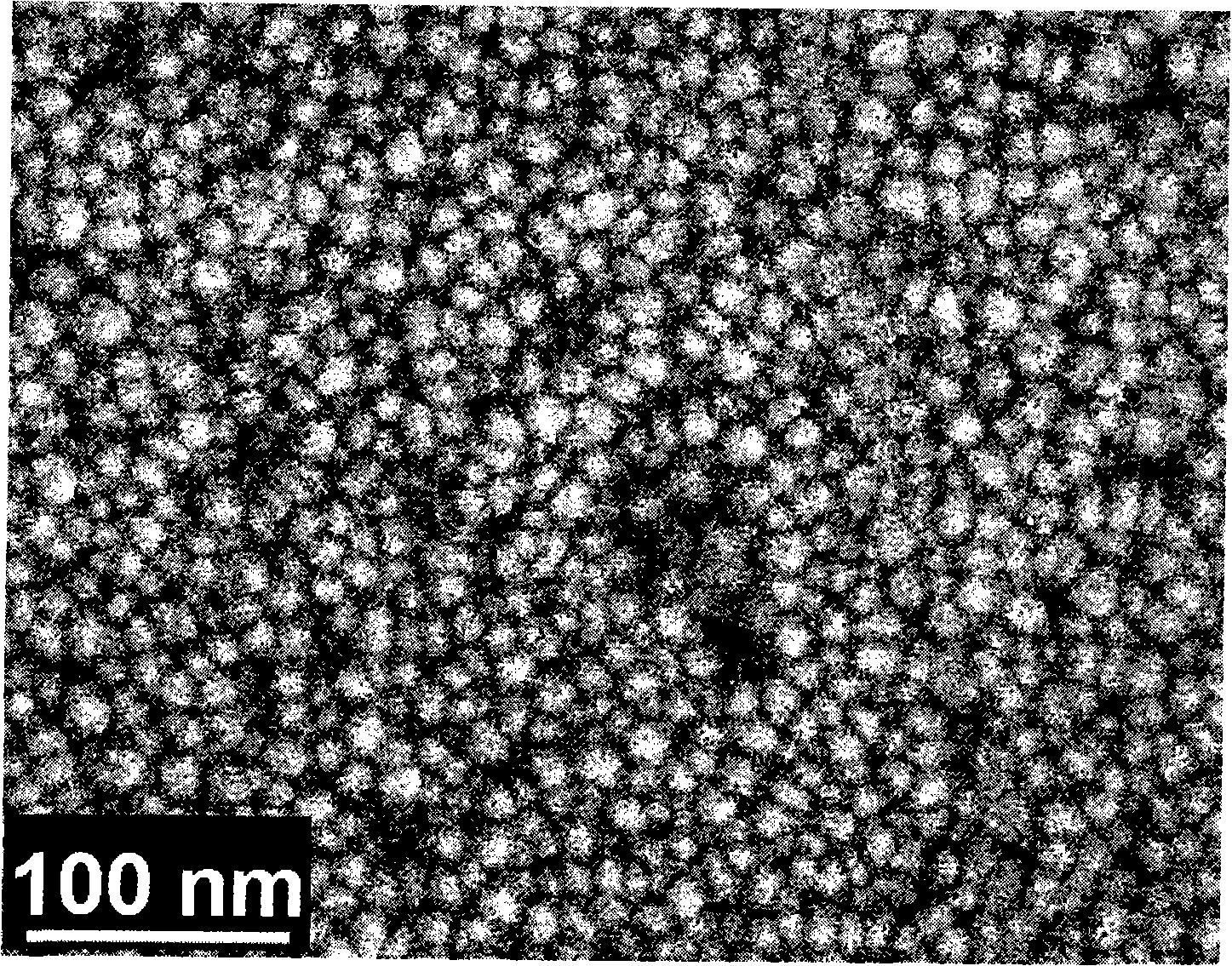

[0024] In the following examples, the prepared broadband wave-absorbing magnetic film is formed by alternately arranging multilayer magnetic layers and non-magnetic isolation layers for magnetic isolation. The film formation process uses traditional radio frequency magnetron sputtering The radiation equipment deposits the upper magnetic layer and the isolation layer layer by layer on the Si surface. When preparing the magnetic layer, a composite target is used, that is, a non-magnetic metal sheet is uniformly placed on the magnetic metal target, such as any one or any combination of Zr, Nb, Hf, Ta, Ti, V , the deposition condition of the magnetic layer is: background vacuum degree -5 Pa, sputtering power 50W corresponds to a power density of 1.7W / cm 2 , the substrate is water-cooled, the Ar flow rate is 20 SCCM, and the Ar pressure is 0.2Pa. In the process of preparing magnetic thin films, the purpose of greatly a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com