Sliding mechanism

A sliding mechanism and component technology, used in mechanical equipment, linear motion bearings, bearings, etc., can solve the problems of high maintenance costs, troublesome and troublesome for users, increase market acceptance, save parts costs, and reduce maintenance costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

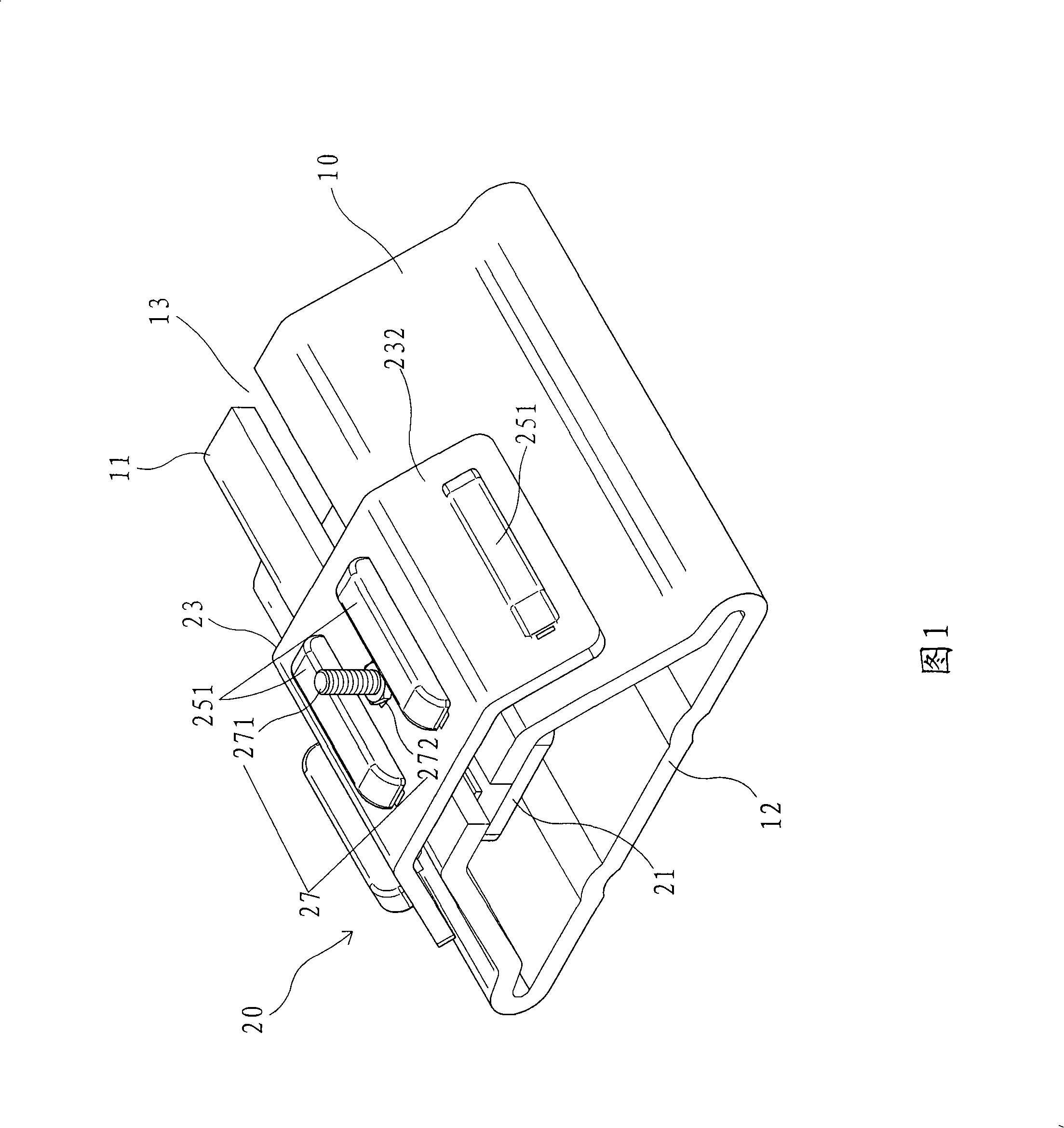

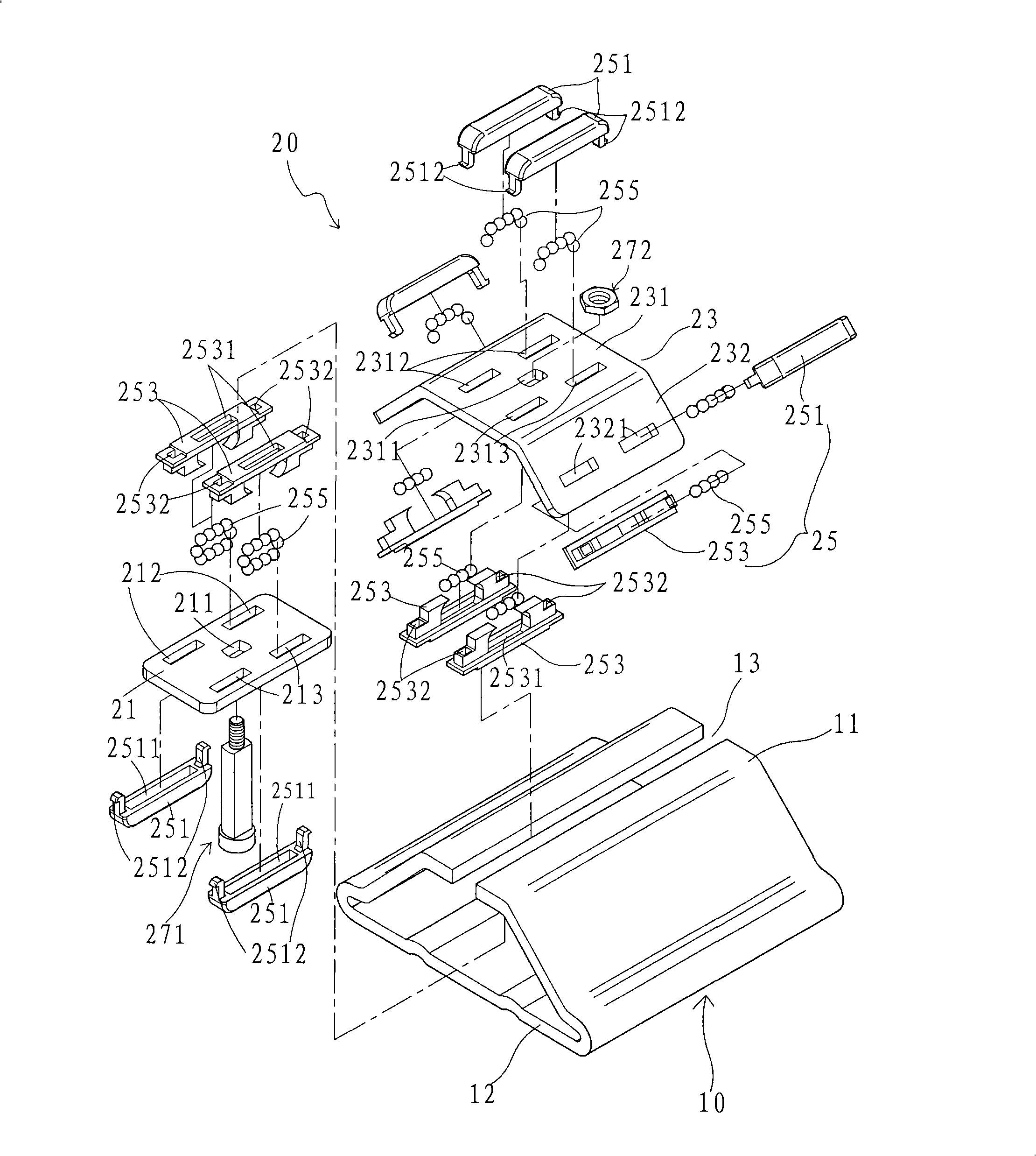

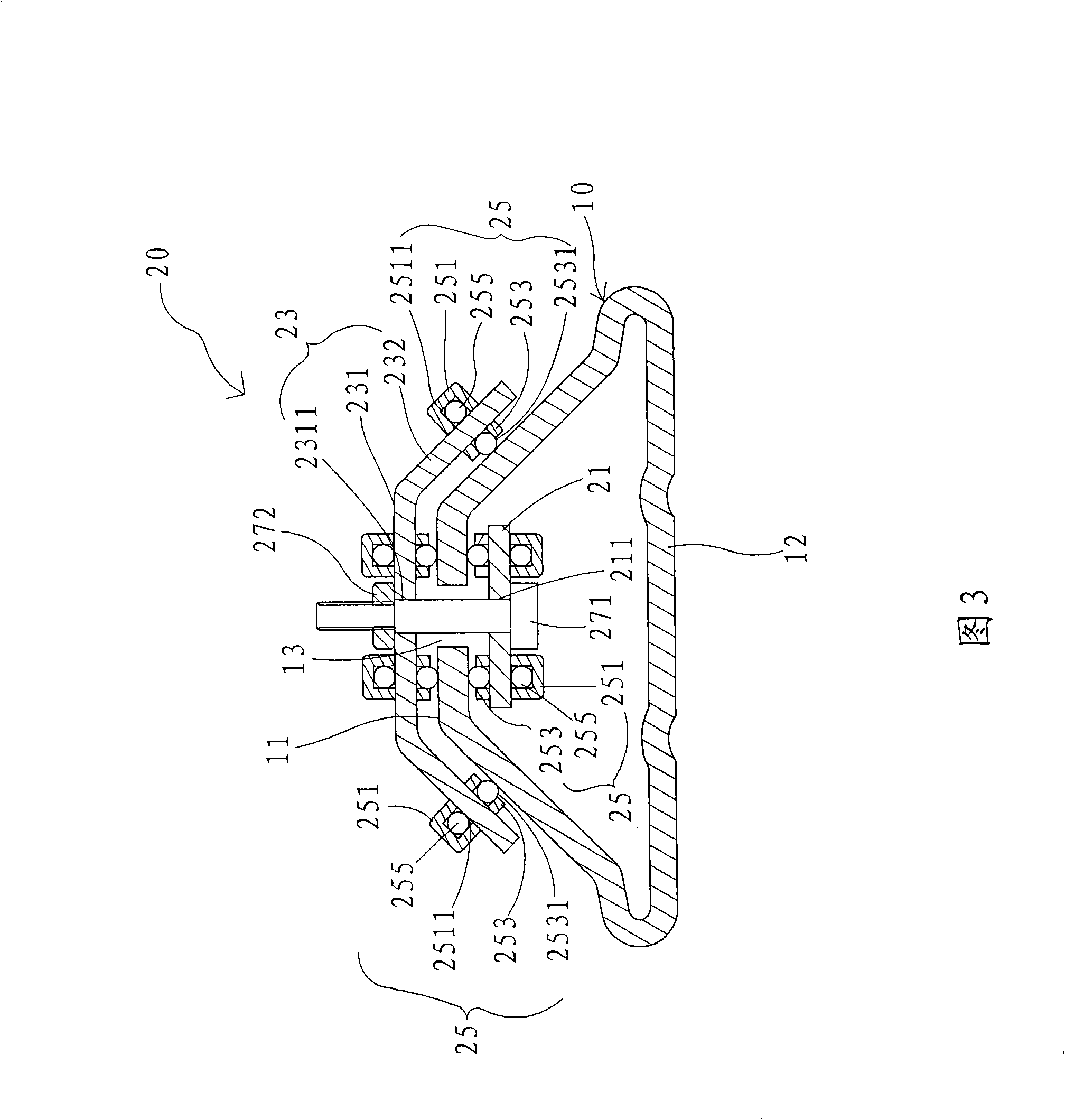

[0042] Please refer to Figures 1 to 3, a sliding mechanism 20 provided by the present invention is installed on a rail 10 in the shape of a hollow plate column, and can slide along a groove 13 provided at the center of the upper end of the rail 10 Displacement person, in the track 10 in the first preferred embodiment of the present invention, it is generally common that its upper bottom 11 width is less than its lower bottom 12 widths and generally is " trapezoidal " shape, and a kind of present invention The sliding mechanism 20 mainly includes: a first plate 21, a second plate 23, a plurality of roller members 25 including a main member 251, a secondary member 253, a plurality of ball bodies 255, and a positioning assembly 27; of which

[0043] The first plate 21 is a long rectangular plate with a width slightly larger than the width of the groove 13 of the track 10, and is arranged on the inside of the track 10 directly below the groove 13, at the center of the plate. Ther...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap