Optical encoder device for small-sized motor

A technology of optical encoders and small motors, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of feasibility and positioning accuracy, and the lack of optical sensor modules, etc., to achieve structural robustness, high Effect of positioning accuracy, reliable positioning and fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

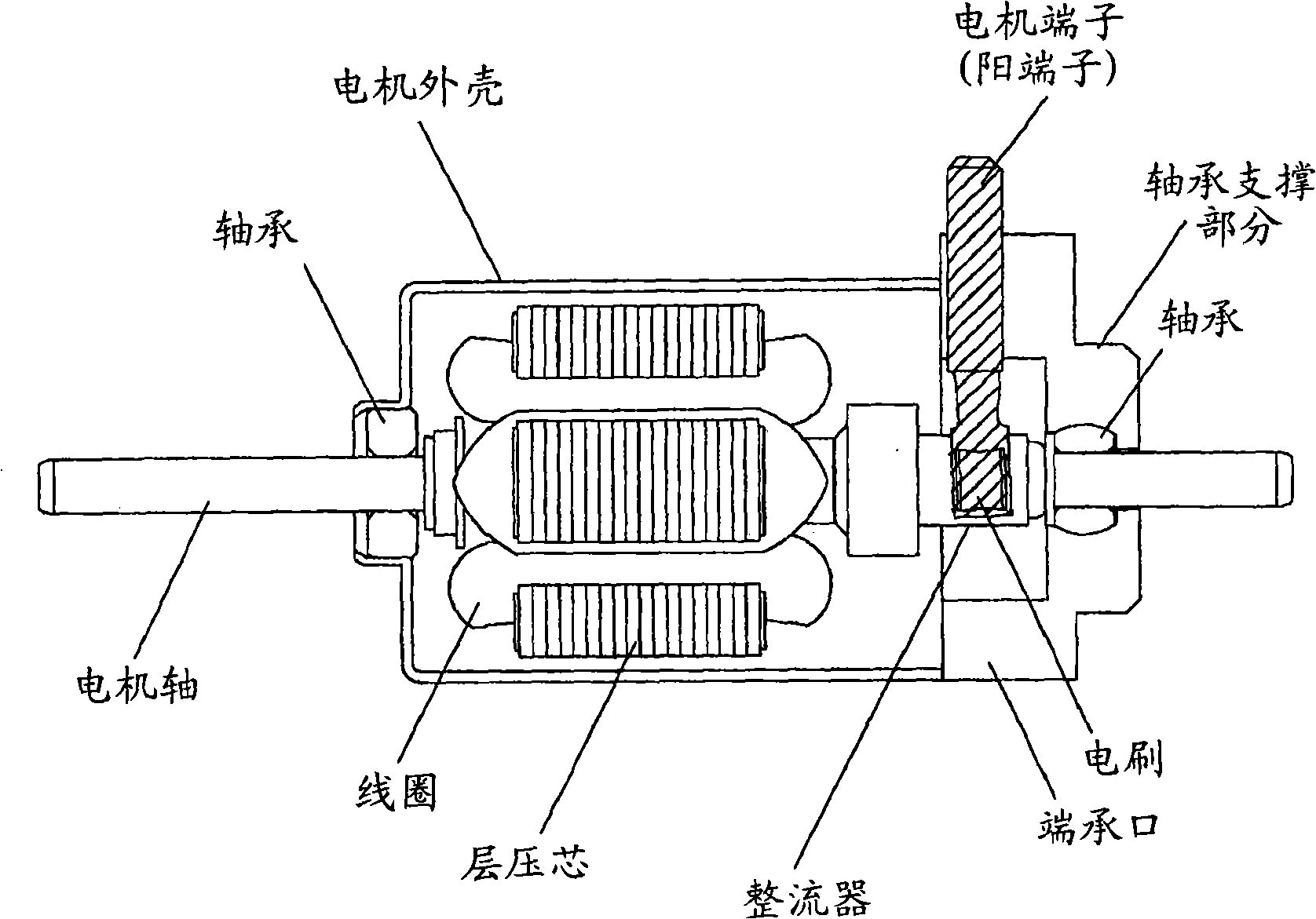

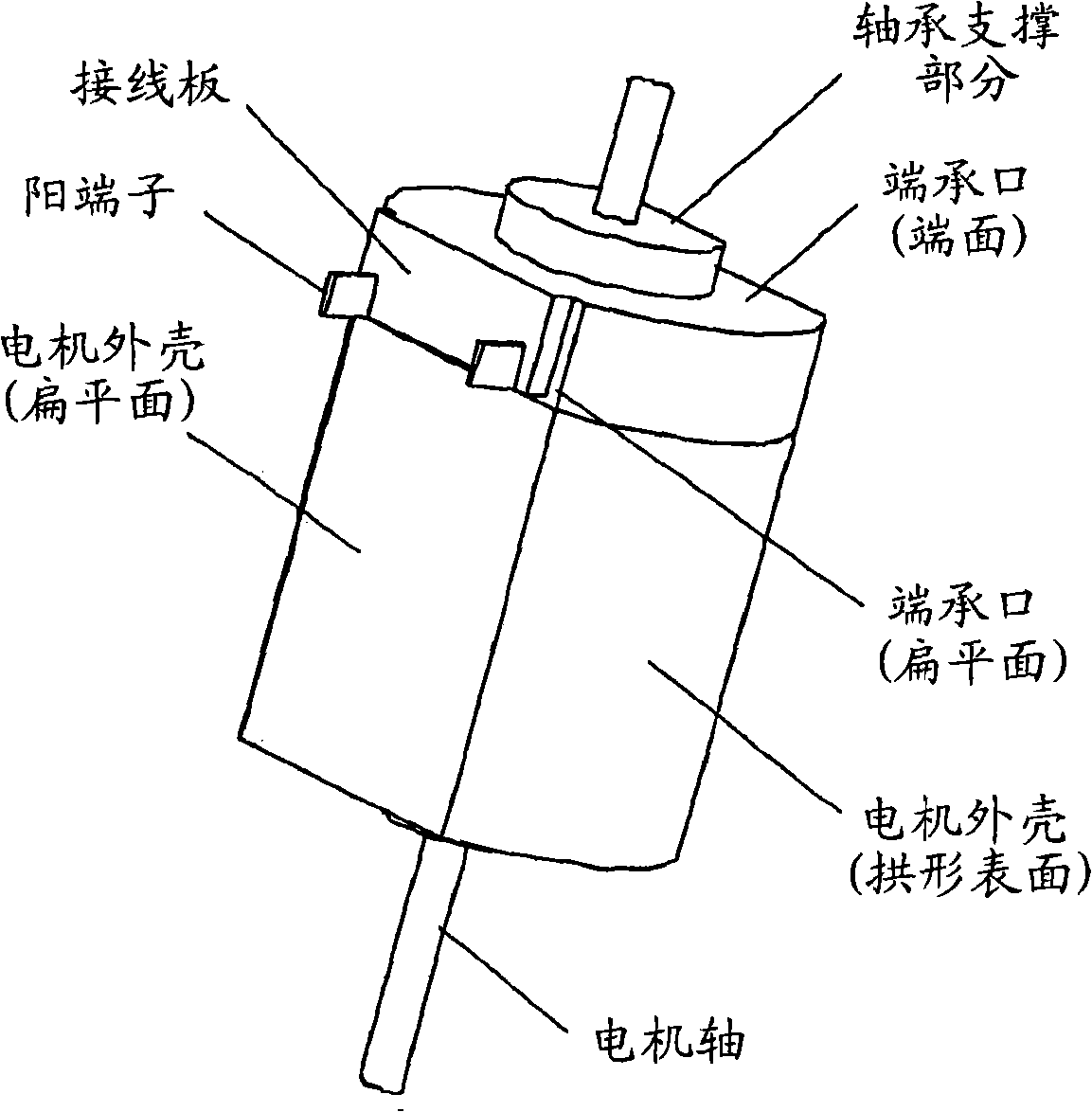

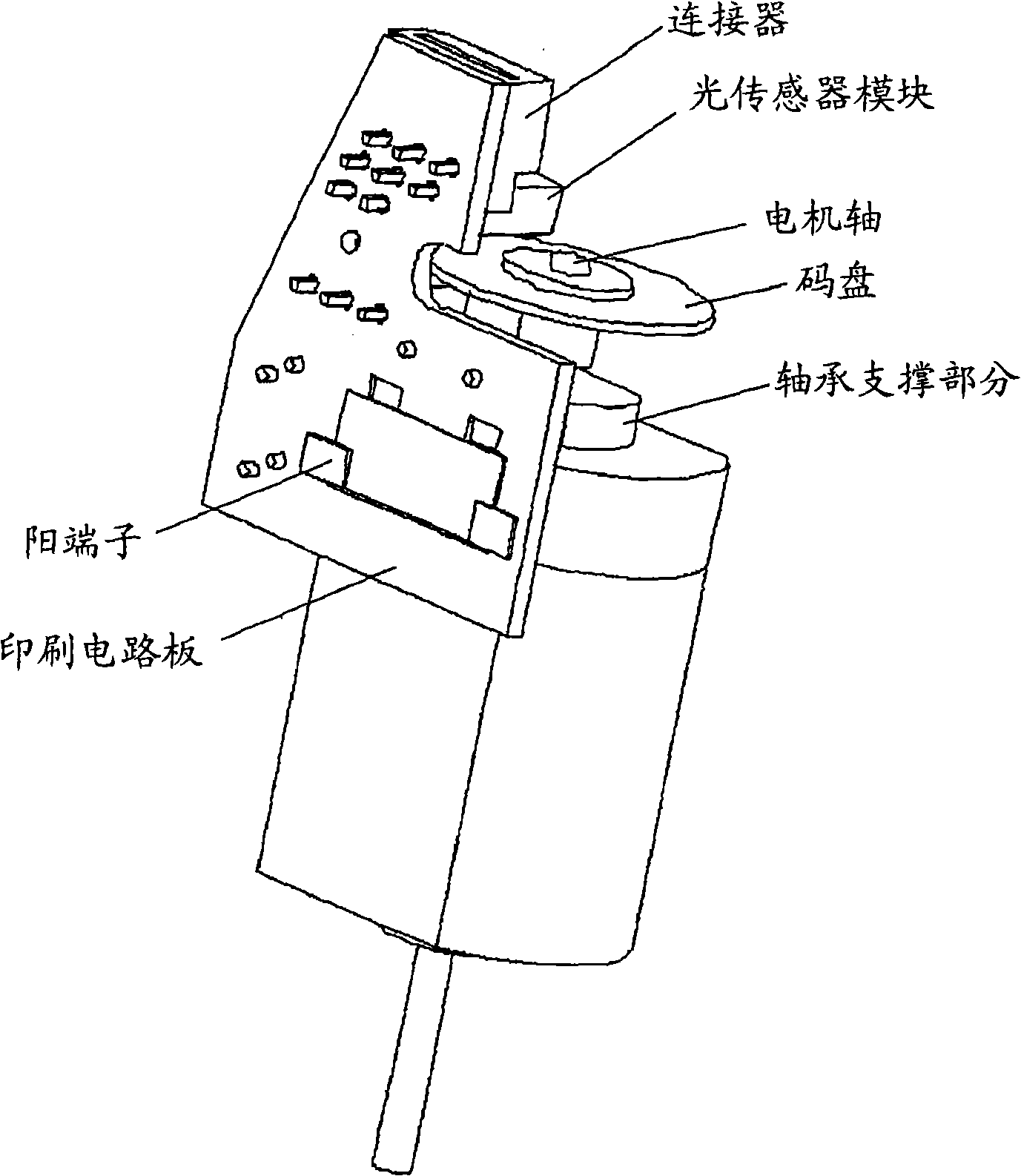

[0012] The invention will now be described by means of examples. Figure 1A Just a cross-sectional view of the motor, positioned so that the flat surface is facing up in this drawing, from which the motor terminals (male terminals) protrude; Figure 1B is a perspective view of the motor viewed from the outside of the motor. A pair of magnets, serving as stator poles, are fixed to the inner surface of the arcuate wall portion of the motor housing made of metal. The rotor is rotatably fixed on the motor housing. The rotor is constructed by integrally assembling a commutator and rotor poles formed from laminated cores and coils onto a motor shaft. The motor housing has flat wall portions (flat faces) on opposite sides and arched wall portions extending between the flat wall portions, so that the motor housing has a bottomed hollow tubular shape as a whole. After the rotor integrally assembled to the motor shaft is inserted into the motor case through its opening, an end socket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com