Fluid pressure shock absorber

一种流体压力、缓冲器的技术,应用在减振器、减震器、弹簧/减震器等方向,能够解决低速区域衰减力大、降低主阀耐久性、难主阀开阀等问题,达到稳定衰减力、提高耐久性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

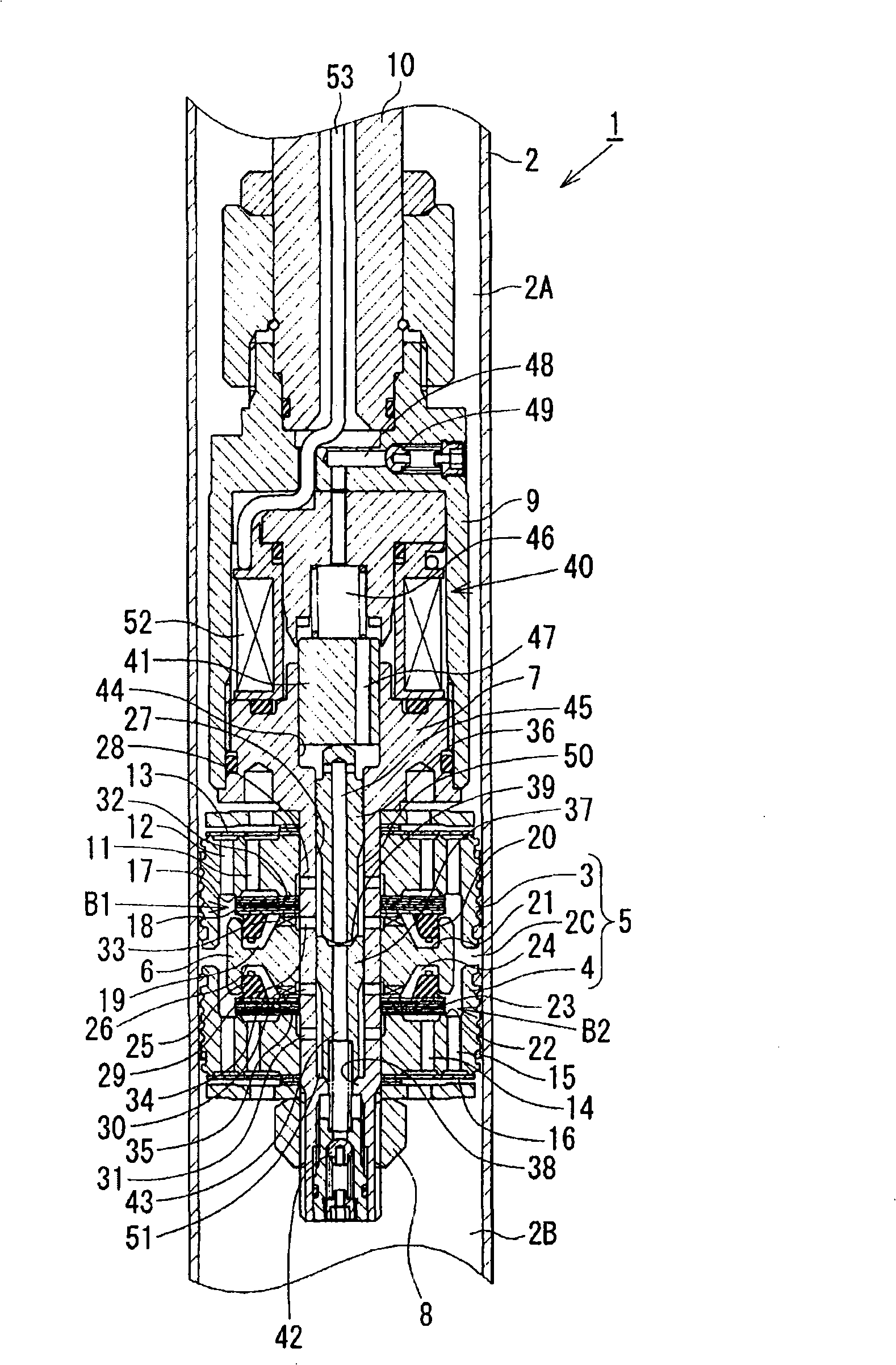

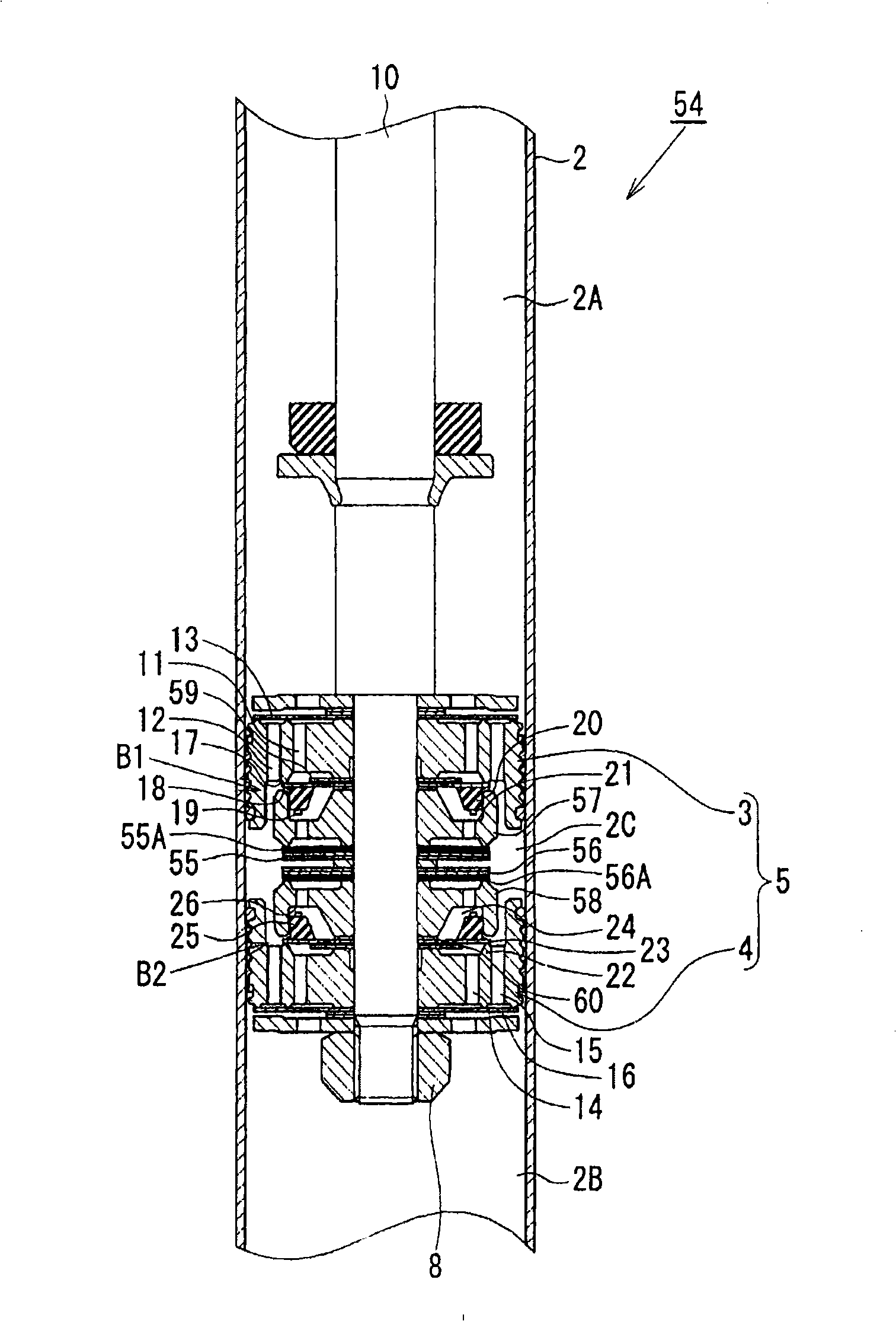

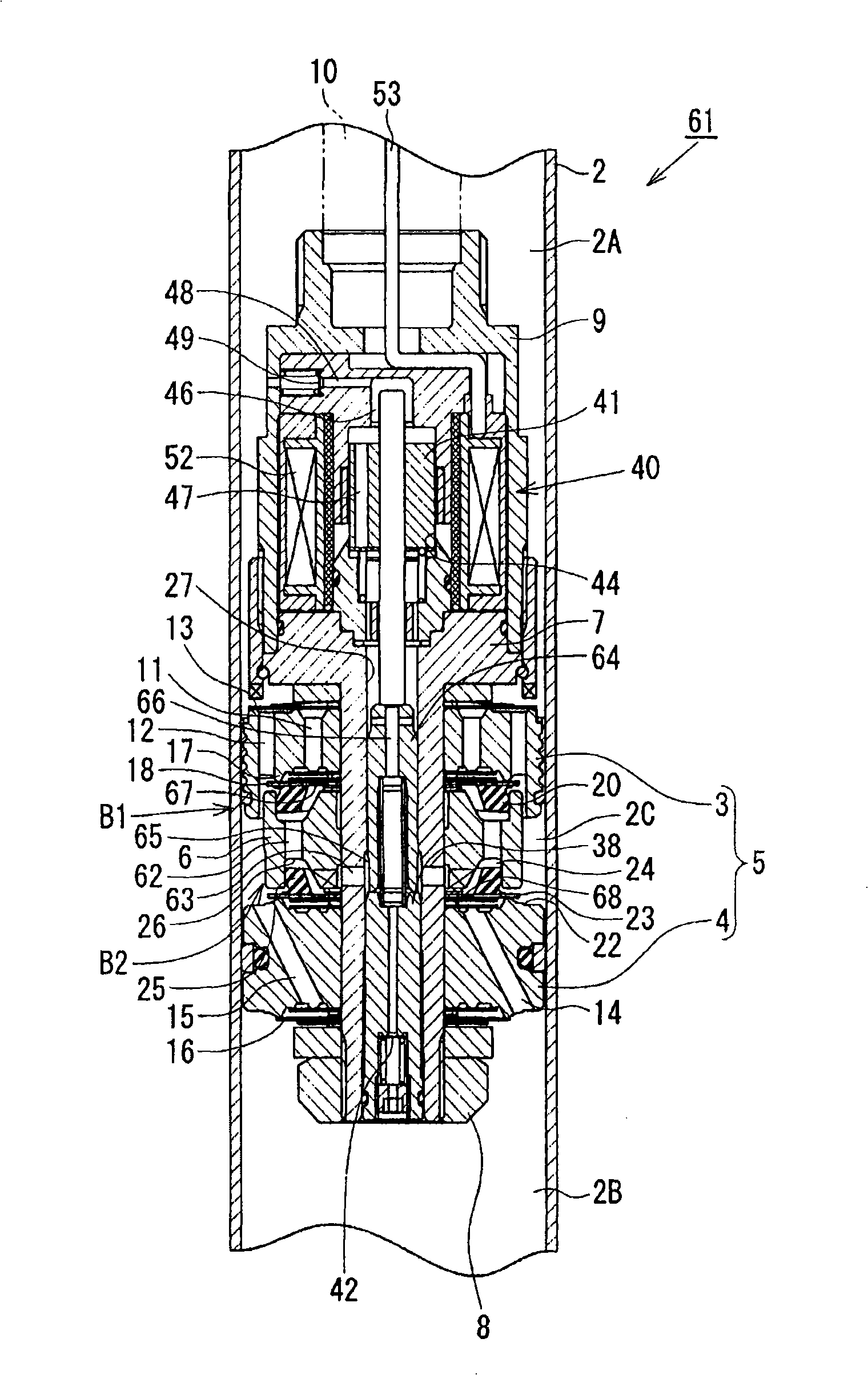

[0036] Embodiments of the present invention will be described in detail below based on the drawings.

[0037] refer to figure 1 The first embodiment of the present invention will be described. Such as figure 1 As shown, the damping force adjustable hydraulic shock absorber 1 (fluid pressure shock absorber) of this embodiment is a cylindrical hydraulic shock absorber, and a piston 5 composed of a first piston 3 and a second piston 4 is slidably embedded in the The cylinder 2 is divided by the piston 5 into two chambers, an upper cylinder chamber 2A and a cylinder lower chamber 2B, and a piston chamber 2C is formed between the first and second pistons 3 and 4 . The first and second pistons 3 , 4 are inserted into a front end portion of a hollow piston bolt 7 and integrally fixed by a nut 8 together with a valve member 6 sandwiched therebetween. A substantially bottomed cylindrical housing 9 is attached to a root end portion (upper portion in the drawing) of the piston bolt 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com