Backlight module group and its optical plate

A backlight module and optical board technology, applied in optics, optical components, nonlinear optics, etc., can solve the problem of uneven light output from the backlight module 100, and achieve the effect of improving the uniformity and uniformity of light output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

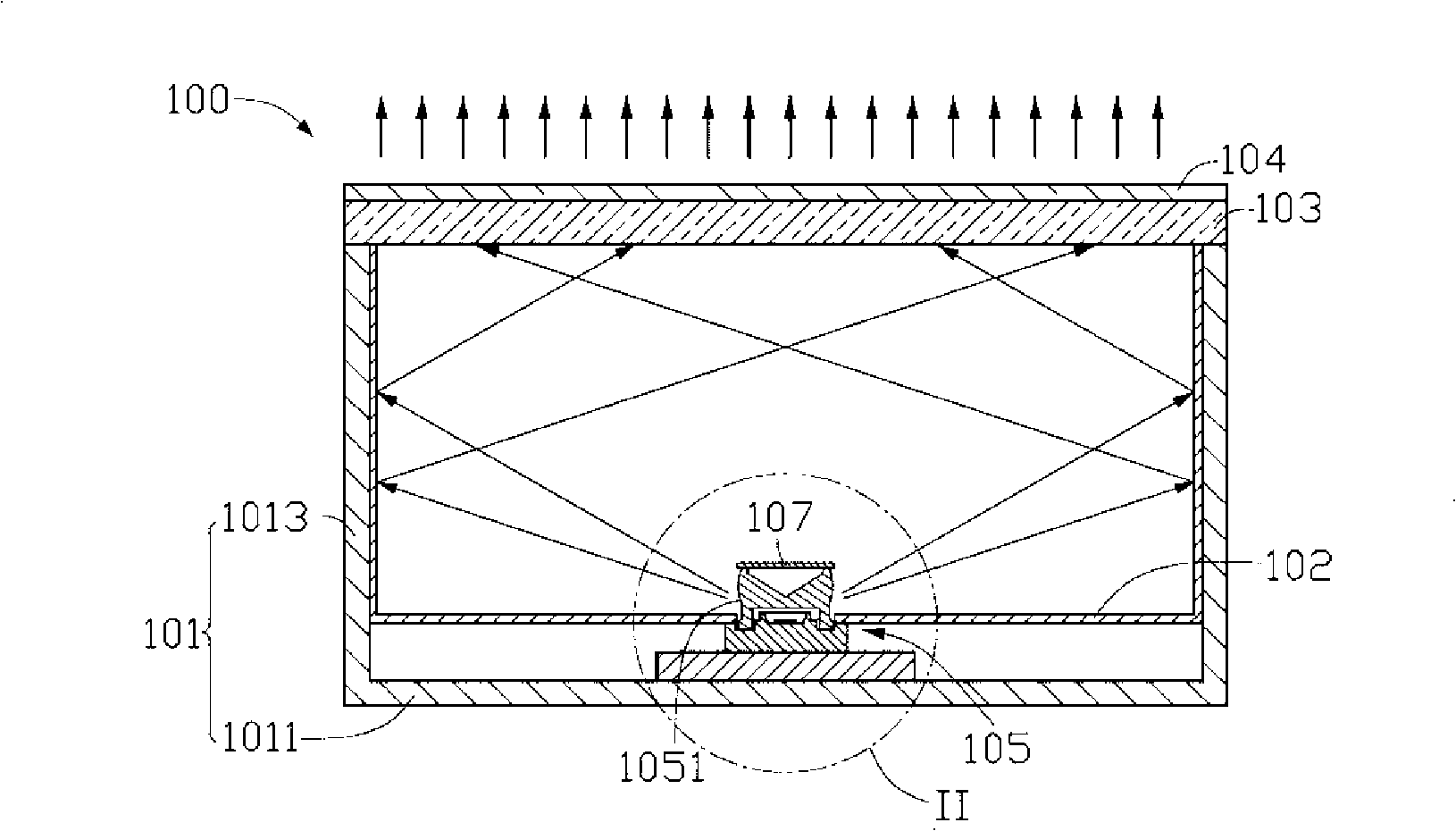

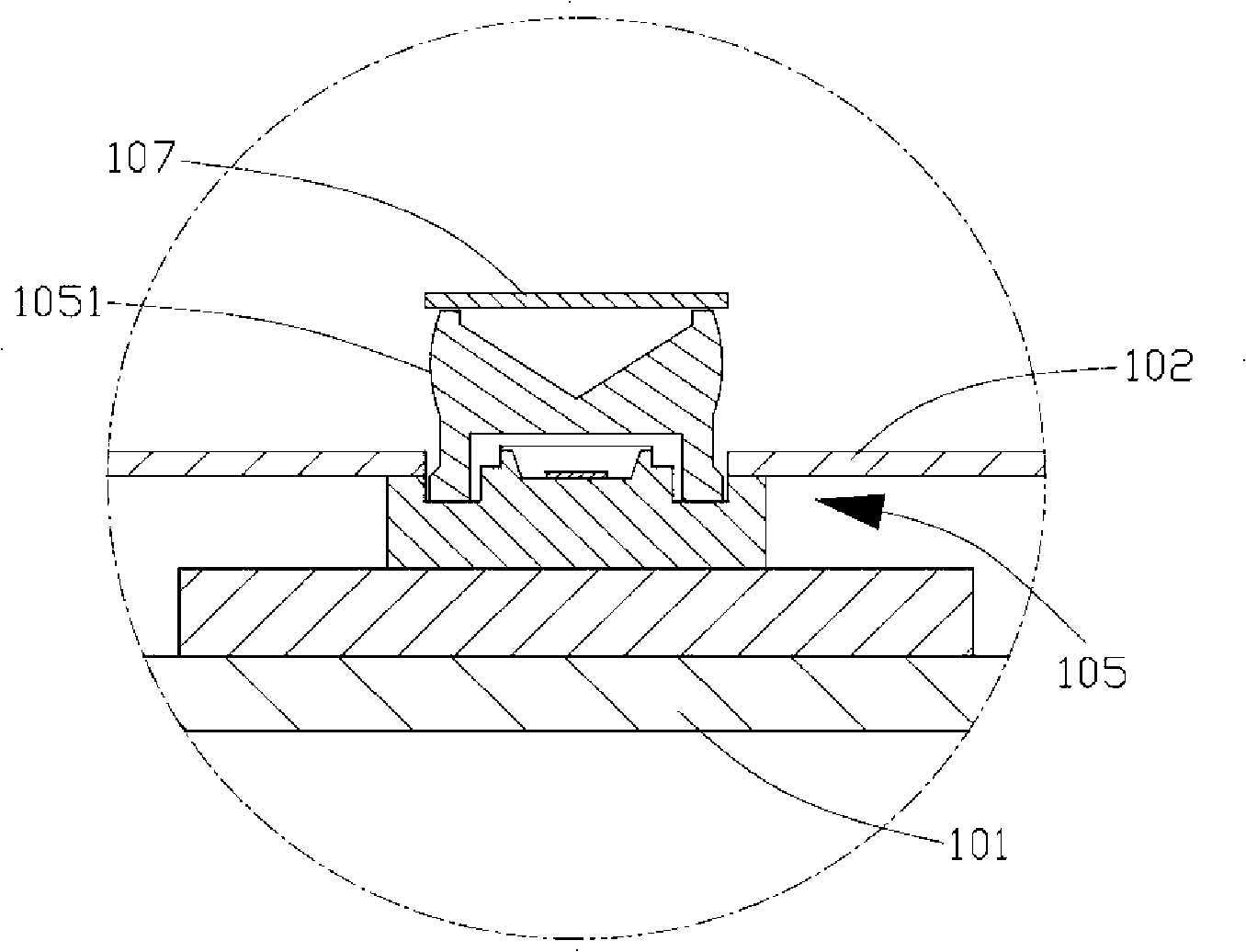

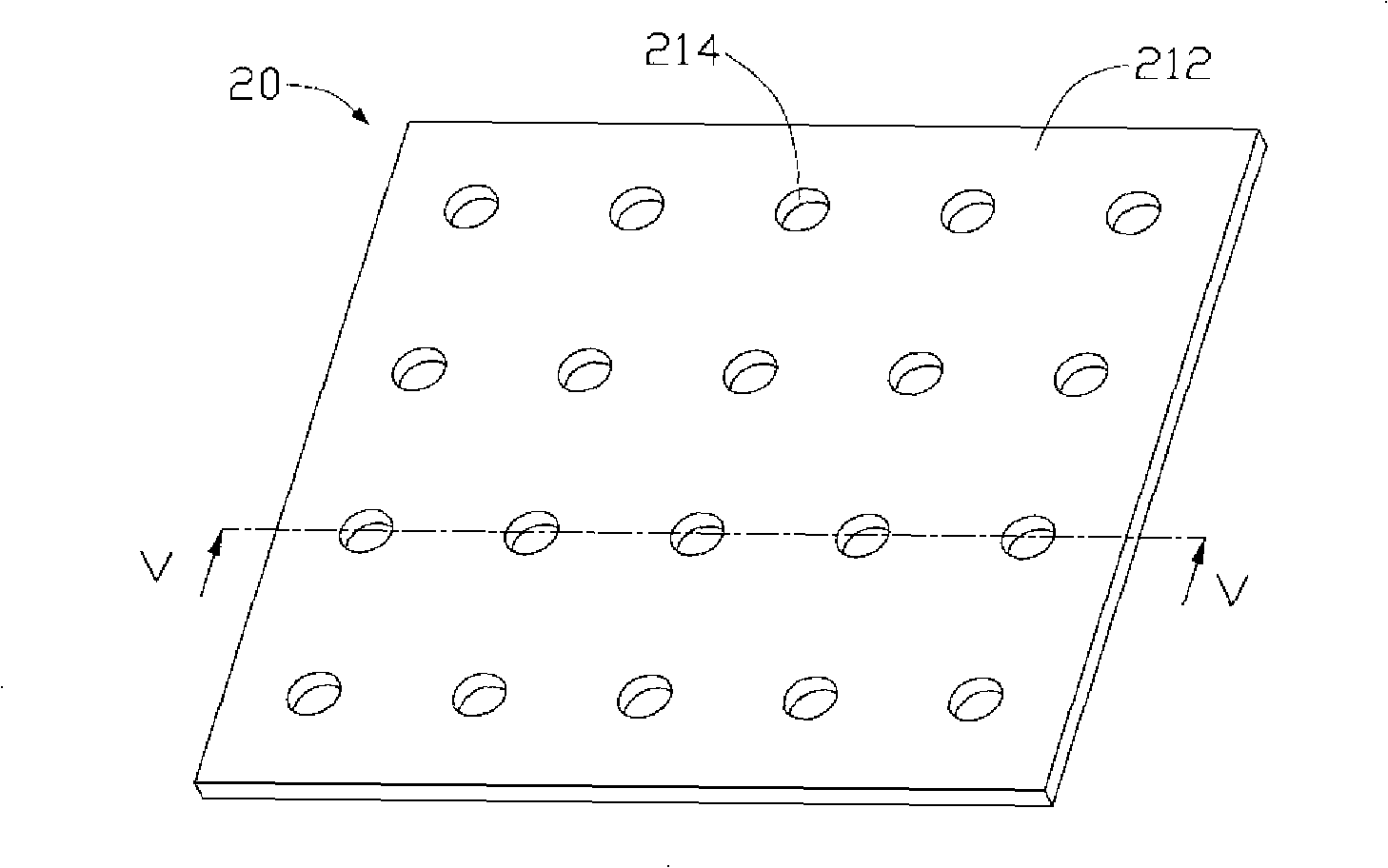

[0024] The optical plate of the present invention will be further described in detail below with reference to the drawings and multiple embodiments.

[0025] Please also refer to image 3 , Figure 4 and Figure 5 , the first preferred embodiment of the present invention provides an optical plate 20 . The optical plate 20 has a square shape and includes a plurality of optical plate units 21 arranged closely in an array. Each optical plate unit 21 includes a light emitting surface 212 and a bottom surface 213 opposite to the light emitting surface 212 . The bottom surface 213 is flat, and each bottom surface 213 defines a light source receiving portion 214 and a plurality of grooves 215 at the center thereof, and the plurality of grooves 215 are respectively located around the light source receiving portion 214 . In this embodiment, the light source receiving portion 214 is a through hole penetrating from the bottom surface 213 to the light emitting surface 212 , and the gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com