Reversed flow slurry circulation immersion technique in corn starch process

A technology of corn starch and cyclic soaking, which is applied in the field of corn deep processing, can solve the problems of non-separation, low total output rate of corn starch factory, and influence on the total output rate, so as to reduce maintenance costs, reduce production time and energy consumption, and reduce processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

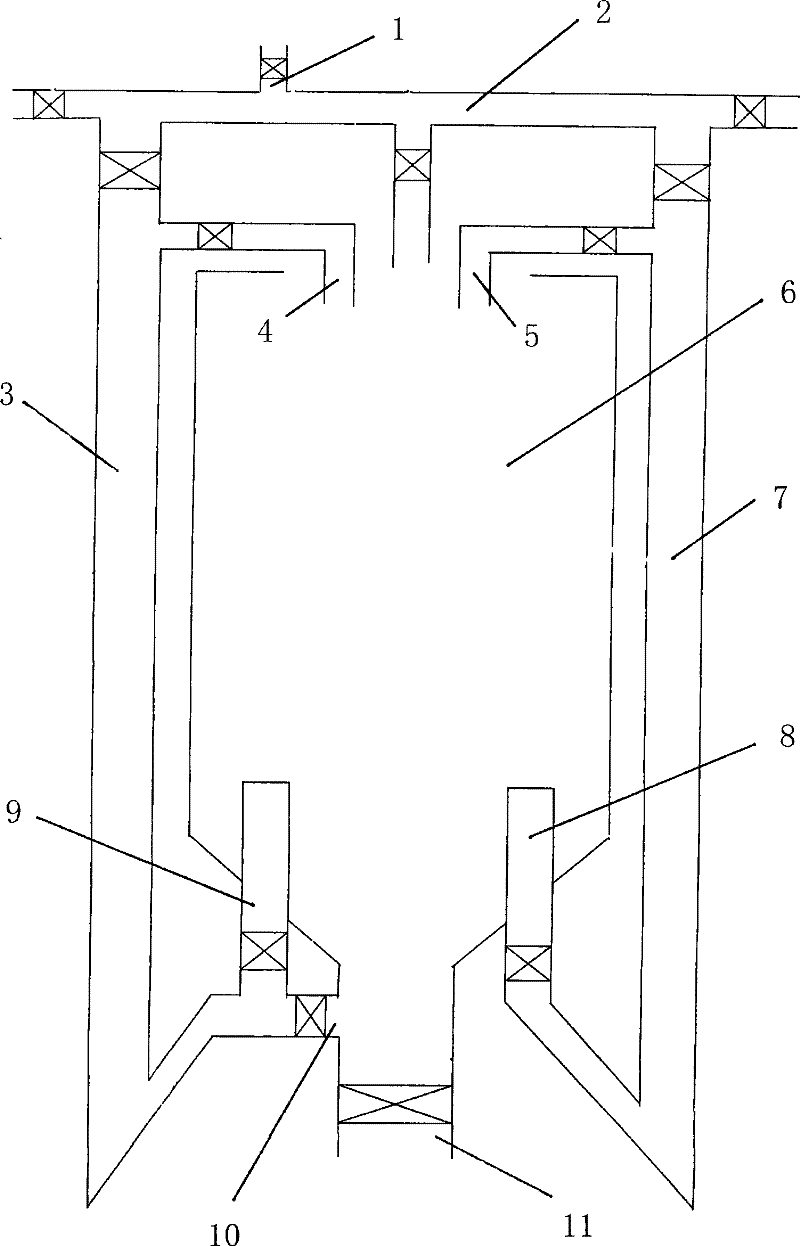

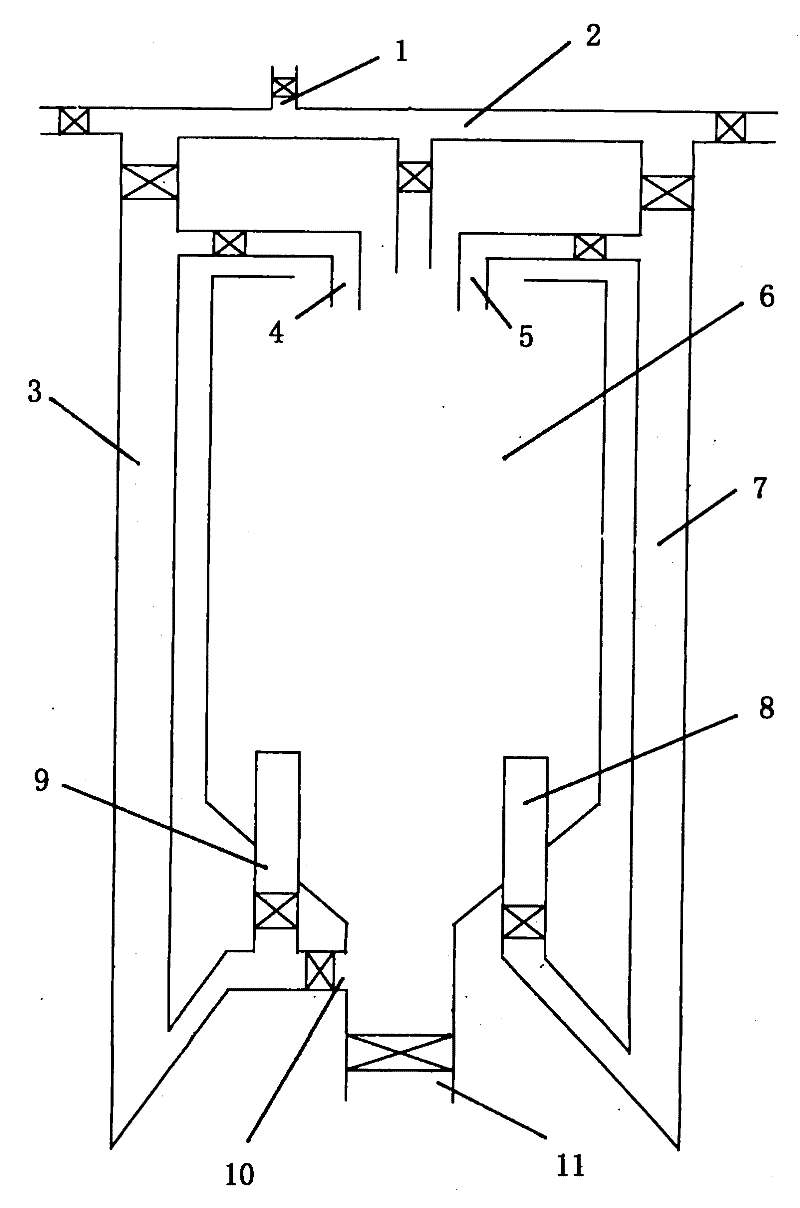

[0008] Such as figure 1 As shown, the corn is soaked in a soaking tank, the temperature of the soaking slurry is 48-50 degrees, the soaking time is 48-52 hours, the soaking slurry is composed of sulfurous acid and water with a concentration of 0.16%-0.18%, and the soaking tank is set There are multiple and interconnected. During the soaking process, the corn flows and circulates in the soaking tank, and the circulation process is: soaking slurry and corn are placed in the soaking tank 6, the corn pump and the heating pump are started, and the corn pump circulates the soaking slurry and corn in the soaking tank from the corn The pipe inlet 10 is inhaled, and the corn and soaking slurry enter the soaking tank 6 from the corn circulating pipe outlet 4 at the top of the soaking tank 6 through the corn circulation pipe 3, and circulate repeatedly, and the heating pump transfers the soaking slurry in the soaking tank 6 from the soaking slurry Inlet 8 is sucked into soaking tank fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com