Reversed flow slurry circulation immersion technique in corn starch process

A technology of corn starch and cyclic soaking, which is applied in the field of corn deep processing, can solve the problems of low total output rate of corn starch factory, affect the total output rate, and cannot be separated, so as to reduce maintenance costs, reduce production time and energy consumption, and reduce processing Effect

Inactive Publication Date: 2008-10-29

窦金玉

View PDF0 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The production principle and equipment of corn starch are basically the same, but if corn starch is produced simply by using the starch production method and equipment of existing starch factory to produce corn starch, it will lead to the following disadvantages: the total output rate of corn starch factory is low, only It reaches about 90%, and the acidity in starch is much higher than the national standard

In corn granules, due to its unique molecular structure, starch and protein are closely connected, and the conventional static soaking method cannot effectively separate them, which directly affects the improvement of the total yield, which can only reach about 90% of the total yield.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

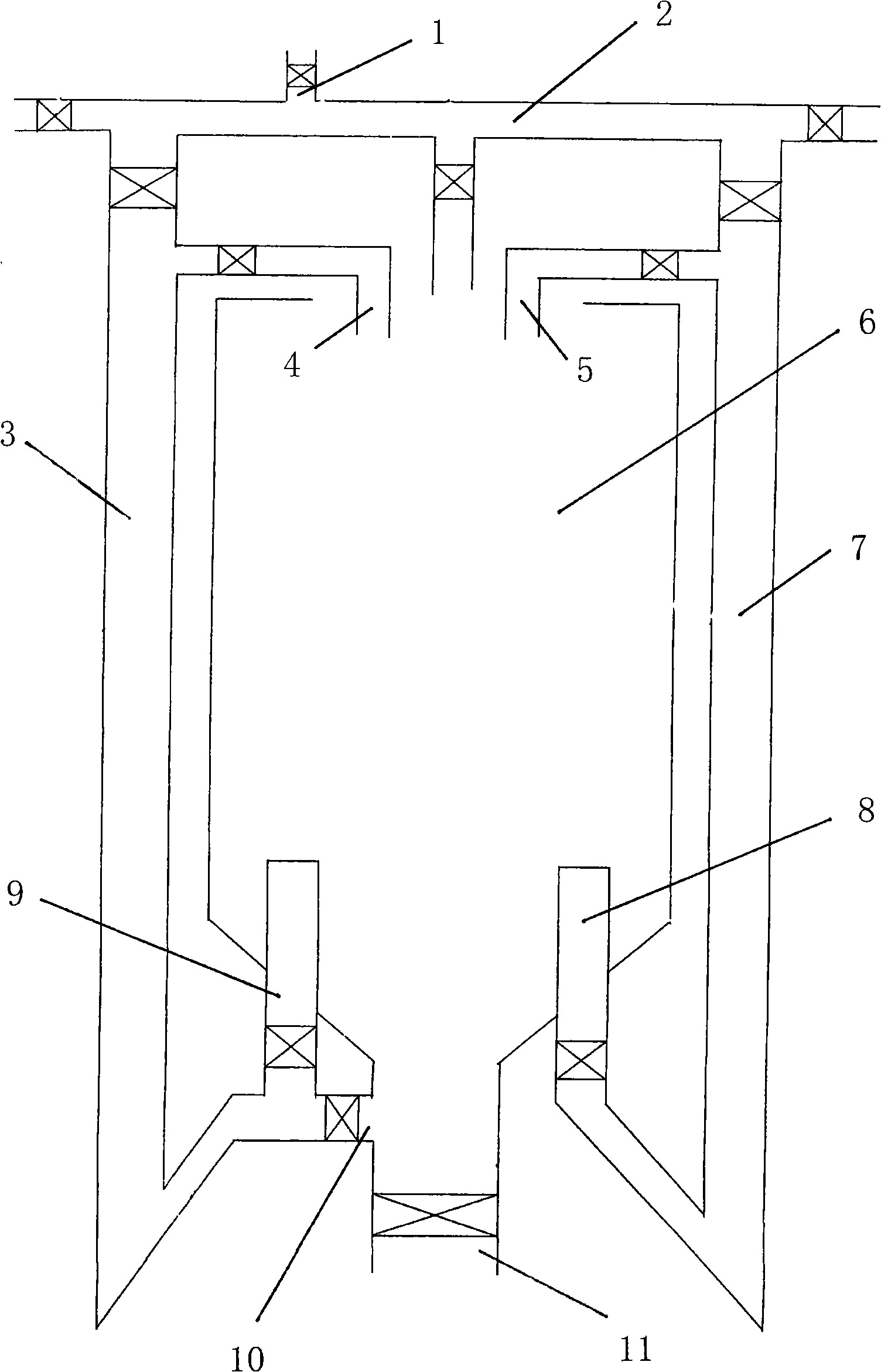

The invention discloses a countercurrent slurry cyclic immersion process used in cornstarch processing, which is characterized in that the process comprises the steps of immersing corn into a plurality of immersion tanks containing immersion slurry for 48-52 hours, wherein the immersion slurry is composed of 0.16-0.18% sulfurous acid and water, and has temperature of 48-50DEG C; and the plurality of immersion tanks communicate with each other. The corn is cyclically immersed in the immersion tanks, instead of the conventional stationary corn immersion. By cyclic immersion of the corn, the endosperm of the corn is effectively swollen, and the total starch yield is improved.

Description

Counterflow Slurry Circulation Soaking Technology in Corn Starch Processing technical field The invention belongs to the technical field of corn deep processing. Background technique Corn starch is a natural polymer material with unique properties. It is widely used in high-grade food, pharmaceutical and other materials, and its economic benefits are very significant. The production principle and equipment of corn starch are basically the same, but if corn starch is produced simply by using the starch production method and equipment of existing starch factory to produce corn starch, it will lead to the following disadvantages: the total output rate of corn starch factory is low, only It reaches about 90%, and the acidity in the starch is much higher than the national standard. The production time per unit of output is long, and the cost of the product is high. The specific analysis is as follows: Because the basic process of corn starch production is: soak the raw corn, ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08B30/02

Inventor 窦金玉

Owner 窦金玉

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com