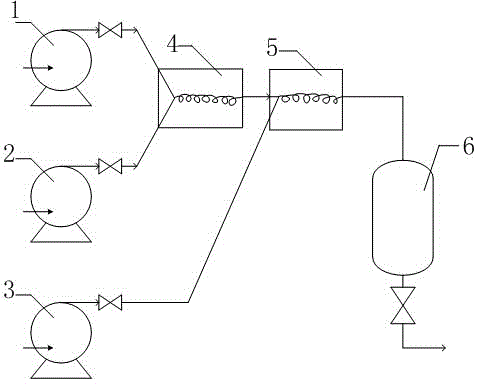

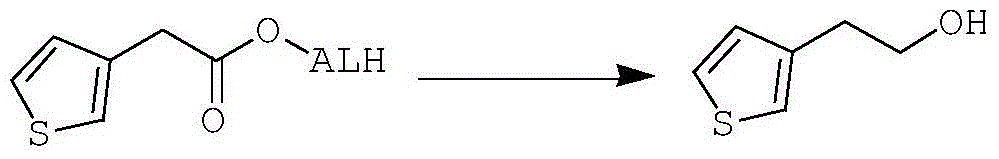

3-thiopheneethanol tubular-type preparation method and device thereof

A thiophene ethanol and tubular technology is applied in the field of tubular preparation of 3-thiophene ethanol, and can solve the problems of difficult isomer impurities and low yield, and achieve the advantages of reducing reaction time, high reaction yield and improving yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The process parameters are as follows:

[0042] The first mixer temperature was -50°C and the second mixer temperature was 0°C.

[0043] The molar ratio of n-butyllithium to 3-bromothiophene is 1.1:1, and the molar ratio of vinyl sulfate to 3-bromothiophene is 1.1:1.

[0044] For pretreatment, 16.2Kg of 3-bromothiophene was dissolved in 90.0Kg of tetrahydrofuran to form a 3-bromothiophene solution; 13.6Kg of vinyl sulfate was dissolved in 30.0Kg of tetrahydrofuran to form a vinyl sulfate solution.

[0045] 30.3Kg n-butyllithium (2.5M n-hexane) in 0.021m 3 / s is pumped into the first mixer, while the 3-bromothiophene solution is at 0.057m 3 / s is pumped into the first mixer, and the temperature of the first mixer is -50°C. At the same time, turn on the flow pump corresponding to the vinyl sulfate solution, and the vinyl sulfate solution will flow at 0.023m 3 / s is pumped into the second mixer and mixed with the prepared 3-thiophene lithium solution, the mixing temper...

Embodiment 2

[0048] The process parameters are as follows:

[0049] The first mixer temperature was -40°C and the second mixer temperature was 10°C.

[0050] The molar ratio of n-butyllithium to 3-bromothiophene is 0.9:1, and the molar ratio of vinyl sulfate to 3-bromothiophene is 0.9:1.

[0051] Raw material pretreatment, 29.7Kg 3-bromothiophene was dissolved in 61.5Kg tetrahydrofuran to form a 3-bromothiophene solution, and 20.4Kg vinyl sulfate was dissolved in 22.5Kg tetrahydrofuran to form a vinyl sulfate solution.

[0052] 70.8Kg n-butyllithium (1.6M n-hexane) at 0.027m 3 / s is pumped into the first mixer, while the 3-bromothiophene solution is at 0.026m 3 / s pumped into the first mixer, the temperature of the first mixer is -40°C. At the same time, turn on the flow pump corresponding to the vinyl sulfate solution, and the vinyl sulfate solution will flow at 0.012m 3 / s is pumped into the second mixer and mixed with the prepared 3-thiophene lithium solution at a mixing temperature ...

Embodiment 3

[0055] The process parameters are as follows:

[0056] The first mixer temperature was -80°C and the second mixer temperature was 20°C.

[0057] The molar ratio of tert-butyllithium to 3-bromothiophene is 1.1:1, and the molar ratio of vinyl sulfate to 3-bromothiophene is 1.1:1.

[0058] Raw material pretreatment, 11.9Kg of 3-bromothiophene was dissolved in 44.0Kg of tetrahydrofuran to form a 3-bromothiophene solution, and 10.0Kg of vinyl sulfate was dissolved in 17.3Kg of tetrahydrofuran to form a vinyl sulfate solution.

[0059] 55.7Kg tert-butyllithium (1.0M n-hexane) at 0.028m 3 / s is pumped into the first mixer, while the 3-bromothiophene solution is at 0.021m 3 / s is pumped into the first mixer, and the temperature of the first mixer is -80°C. At the same time, turn on the flow pump corresponding to the vinyl sulfate solution, and the vinyl sulfate solution will flow at 0.010m 3 / s is pumped into the second mixer and mixed with the prepared 3-thiophene lithium solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com