Tubular preparation method and device of 3-thiophene ethanol

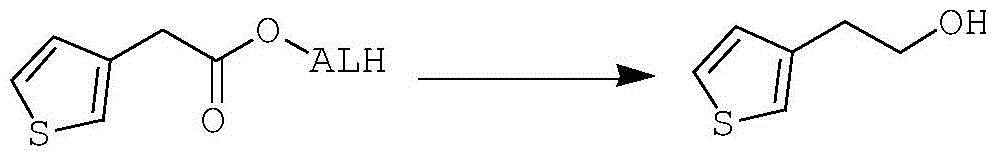

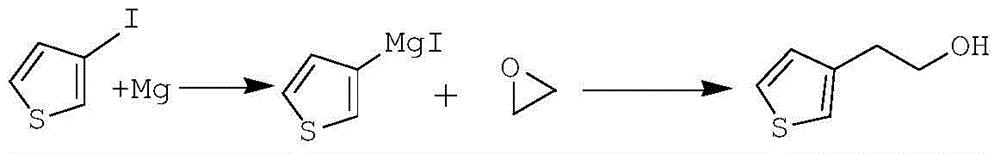

A thiophene ethanol and tubular technology, which is applied in the field of tubular preparation of 3-thiophene ethanol, can solve the problems of difficult isomer impurities, low yield and the like, and achieves the advantages of reduced reaction time, high reaction yield and simple process route. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

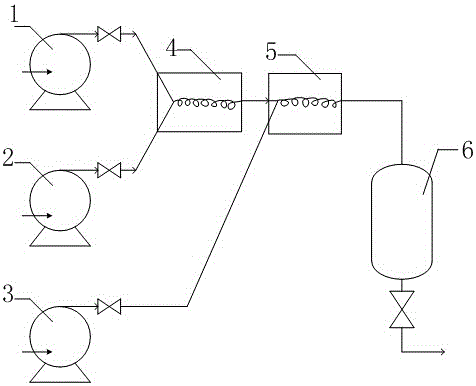

[0041] The process parameters are as follows:

[0042] The first mixer temperature was -50°C and the second mixer temperature was 0°C.

[0043] The molar ratio of n-butyllithium to 3-bromothiophene is 1.1:1, and the molar ratio of vinyl sulfate to 3-bromothiophene is 1.1:1.

[0044] For pretreatment, 16.2Kg of 3-bromothiophene was dissolved in 90.0Kg of tetrahydrofuran to form a 3-bromothiophene solution; 13.6Kg of vinyl sulfate was dissolved in 30.0Kg of tetrahydrofuran to form a vinyl sulfate solution.

[0045] 30.3Kg n-butyllithium (2.5M n-hexane) in 0.021m 3 / s is pumped into the first mixer, while the 3-bromothiophene solution is at 0.057m 3 / s is pumped into the first mixer, and the temperature of the first mixer is -50°C. At the same time, turn on the flow pump corresponding to the vinyl sulfate solution, and the vinyl sulfate solution will flow at 0.023m 3 / s is pumped into the second mixer and mixed with the prepared 3-thiophene lithium solution, the mixing temper...

Embodiment 2

[0048] The process parameters are as follows:

[0049] The first mixer temperature was -40°C and the second mixer temperature was 10°C.

[0050] The molar ratio of n-butyllithium to 3-bromothiophene is 0.9:1, and the molar ratio of vinyl sulfate to 3-bromothiophene is 0.9:1.

[0051] Raw material pretreatment, 29.7Kg 3-bromothiophene was dissolved in 61.5Kg tetrahydrofuran to form a 3-bromothiophene solution, and 20.4Kg vinyl sulfate was dissolved in 22.5Kg tetrahydrofuran to form a vinyl sulfate solution.

[0052] 70.8Kg n-butyllithium (1.6M n-hexane) at 0.027m 3 / s is pumped into the first mixer, while the 3-bromothiophene solution is at 0.026m 3 / s pumped into the first mixer, the temperature of the first mixer is -40°C. At the same time, turn on the flow pump corresponding to the vinyl sulfate solution, and the vinyl sulfate solution will flow at 0.012m 3 / s is pumped into the second mixer and mixed with the prepared 3-thiophene lithium solution at a mixing temperature ...

Embodiment 3

[0055] The process parameters are as follows:

[0056] The first mixer temperature was -80°C and the second mixer temperature was 20°C.

[0057] The molar ratio of tert-butyllithium to 3-bromothiophene is 1.1:1, and the molar ratio of vinyl sulfate to 3-bromothiophene is 1.1:1.

[0058] Raw material pretreatment, 11.9Kg of 3-bromothiophene was dissolved in 44.0Kg of tetrahydrofuran to form a 3-bromothiophene solution, and 10.0Kg of vinyl sulfate was dissolved in 17.3Kg of tetrahydrofuran to form a vinyl sulfate solution.

[0059] 55.7Kg tert-butyllithium (1.0M n-hexane) at 0.028m 3 / s is pumped into the first mixer, while the 3-bromothiophene solution is at 0.021m 3 / s is pumped into the first mixer, and the temperature of the first mixer is -80°C. At the same time, turn on the flow pump corresponding to the vinyl sulfate solution, and the vinyl sulfate solution will flow at 0.010m 3 / s is pumped into the second mixer and mixed with the prepared 3-thiophene lithium solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com