Maotai-flavor Daqu liquor stable pile fermentation process

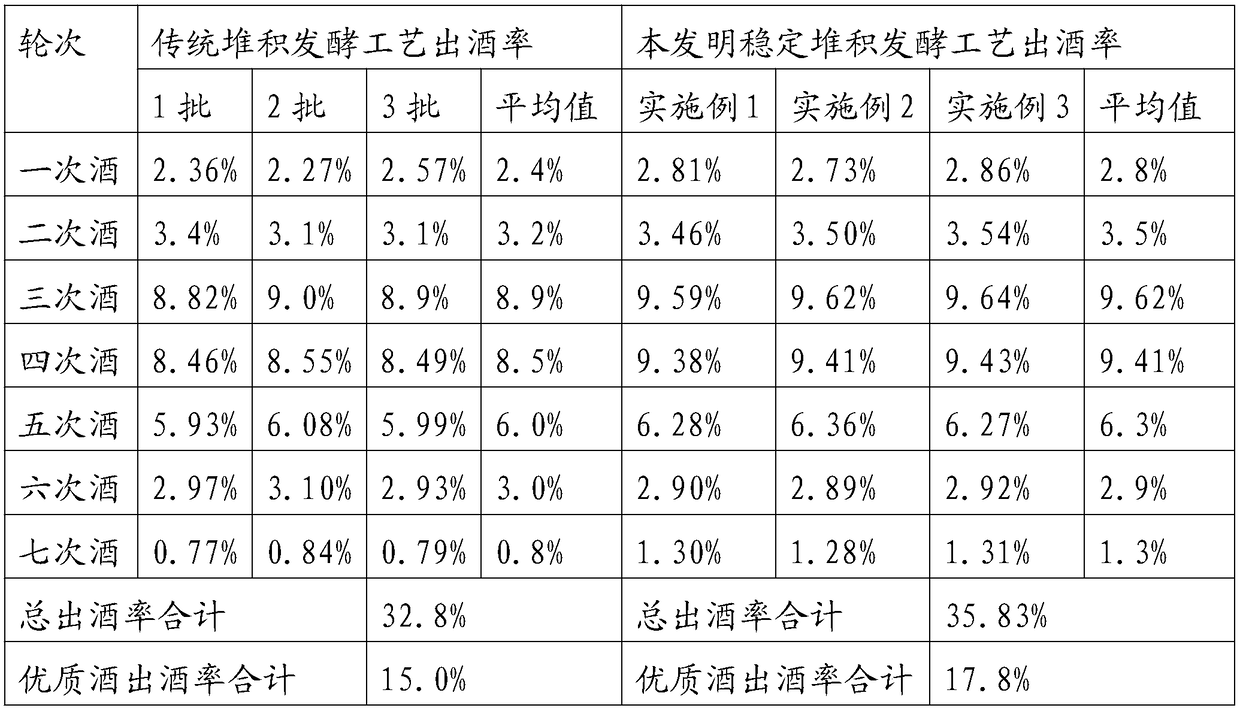

A stacking fermentation and fermentation process technology, which is applied in the field of wine making, can solve the problems of long stacking fermentation time, low fermentation temperature, and long production time, and achieve the effects of enhanced stacking fermentation, simple process, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A stable accumulation fermentation process for Maotai-flavor Daqu liquor, comprising the following steps:

[0033] (1) Add the sorghum and wheat after impurity removal and crushing treatment for wine making according to the ratio of 95:5 by weight, and the feeding amount of lower sand and rough sand account for 50% of the total feeding amount respectively, wherein the whole grain and the The weight ratio of broken grains is: lower sand 8.5:1.5, coarse sand 7.5:2.5;

[0034] (2) Add 48% of raw material weight, hot water at 95°C, moisten the grain, and steam the material twice for 90 minutes and 100 minutes respectively;

[0035] (3) Add 95°C hot water with 1% of raw materials after taking out the retort, stir and let it cool, and add high-temperature Daqu when the temperature drops to 29°C (the weight ratio of yellow koji, white koji and black koji is 8:1:1) , stir, and then add the tail wine of 1% by weight of the sanding material, and mix well;

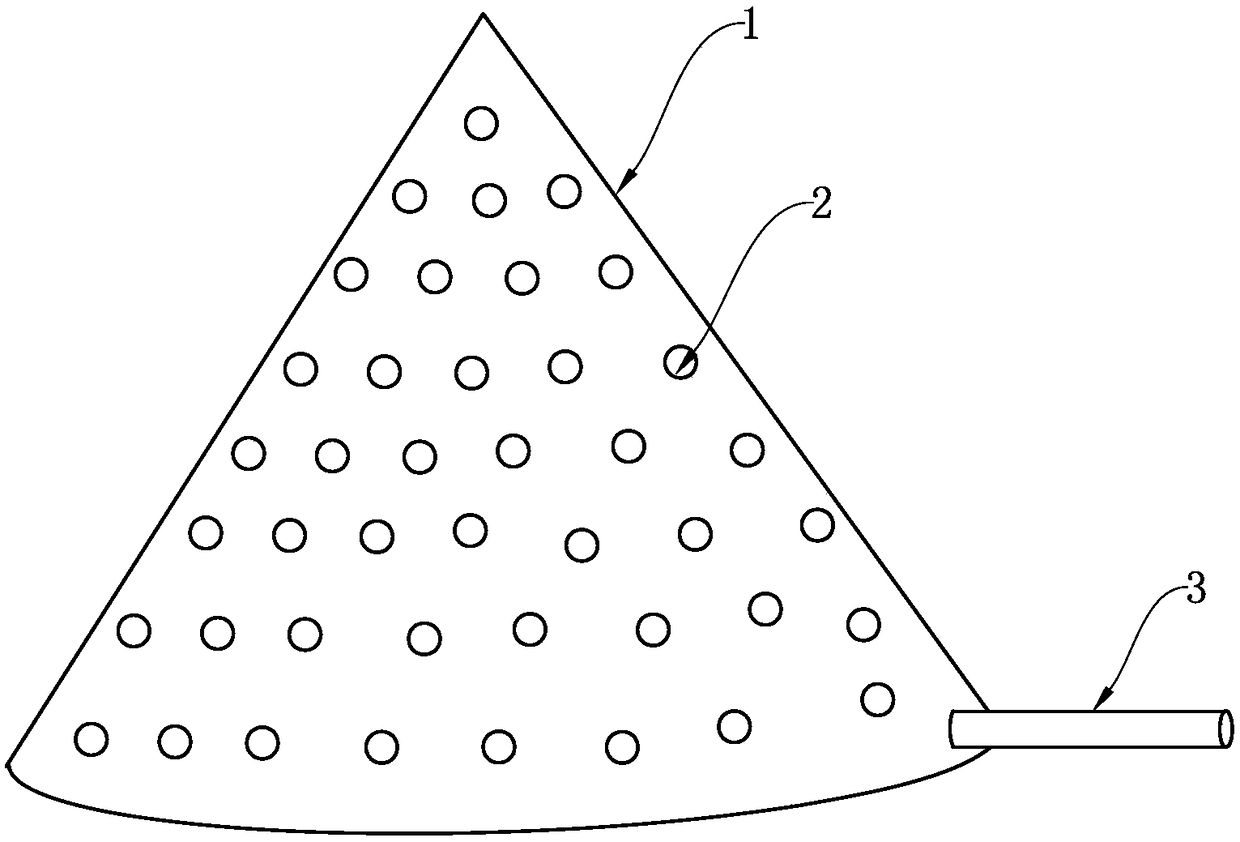

[0036] (4) Set a con...

Embodiment 2

[0043] A stable accumulation fermentation process for Maotai-flavor Daqu liquor, comprising the following steps:

[0044] (1) Add the sorghum and wheat after impurity removal and crushing treatment for wine making according to the ratio of 95:5 by weight, and the feeding amount of lower sand and rough sand account for 50% of the total feeding amount respectively, wherein the whole grain and the The weight ratio of broken grains is: lower sand 8.0:2.0, rough sand 7.0:3.0;

[0045] (2) Add 50% of the raw material weight, hot water at 97°C, moisten the grain, and steam the material twice for 100 minutes and 110 minutes respectively;

[0046] (3) Add 97°C hot water with 2% of raw materials after taking out the retort, stir and let it cool, and add high-temperature Daqu when the temperature drops to 33°C (the weight ratio of yellow koji, white koji and black koji is 7:1.5:1) , stir, and then add the tail wine with an amount of 3% sand, and mix well;

[0047] (4) Set a conical iso...

Embodiment 3

[0054] A stable accumulation fermentation process for Maotai-flavor Daqu liquor, comprising the following steps:

[0055] (1) Add the sorghum and wheat after impurity removal and crushing treatment for wine making according to the ratio of 95:5 by weight, and the feeding amount of lower sand and rough sand account for 50% of the total feeding amount respectively, wherein the whole grain and the The weight ratio of broken grains is: lower sand 8.5:1.5, coarse sand 7.5:2.5;

[0056] (2) Add 52% of the raw material weight, hot water at 99°C, moisten the grain, and steam the material twice for 110 minutes and 120 minutes respectively;

[0057] (3) Add 99°C hot water with 4% of raw materials after taking out the retort, stir and let it cool, and add high-temperature Daqu when the temperature drops to 36°C (the weight ratio of yellow koji, white koji and black koji is 8:1:1) , stir, and then add the tail wine with a feeding amount of 4% by weight of the sand, and mix well;

[0058...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com