Split type se-drum with circulating replaceable powder box

A split-type, toner cartridge technology, applied in the electrical recording process using charge graphics, equipment using electrical recording technology using charge graphics, and electrography, can solve problems such as waste, achieve hygienic replacement, save printing office costs, Easy replacement of toner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The split-type toner cartridge designed by the present invention can be cyclically replaced with the toner cartridge in conjunction with the accompanying drawings and embodiments in detail as follows:

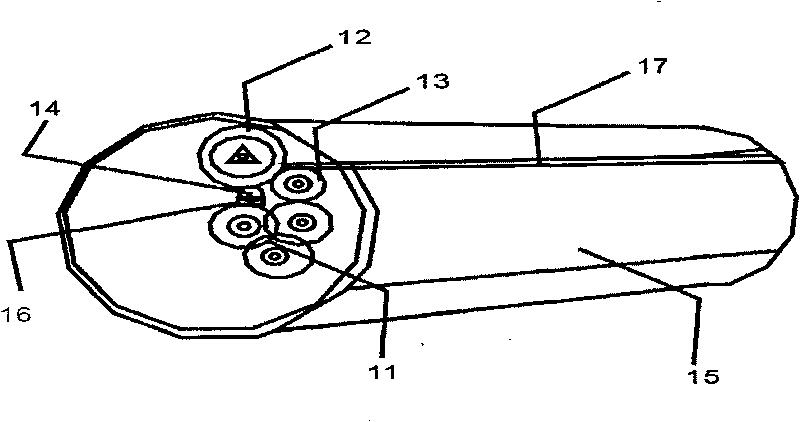

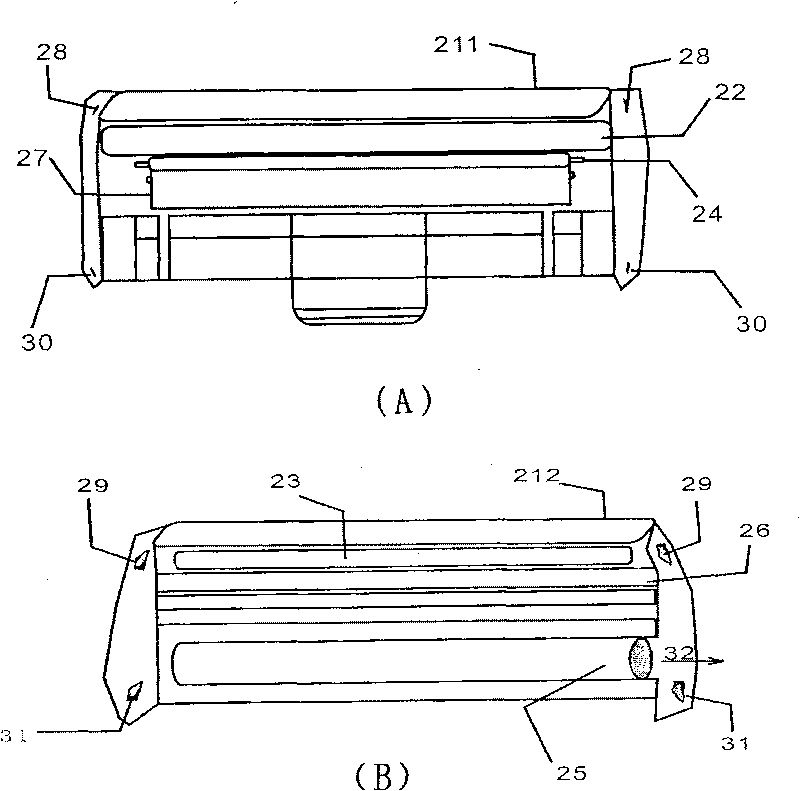

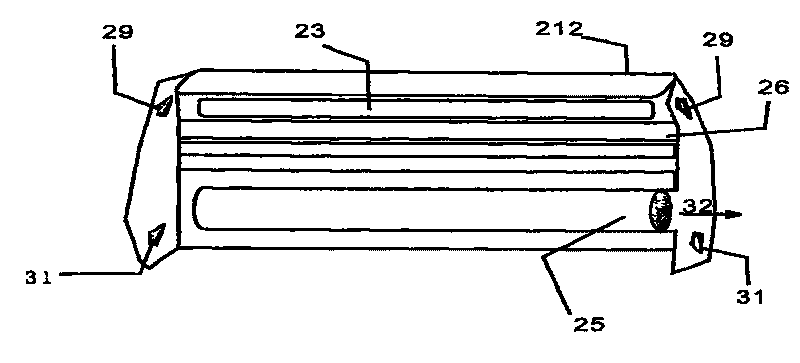

[0014] The split-type toner cartridge designed by the present invention can be cyclically replaced with a powder cartridge, and its structure is as follows: figure 2 As shown, it includes three separable parts assembled: one: consisting of an upper semicircular casing 211, a photosensitive drum (OPC) 22 installed in the casing, a charging roller 24, a waste toner collection bin and a sealing blade ( not shown in the figure), the printing parts composed of buckles 28, 30 installed on the two ends of the shell, such as figure 2 (A) shown. Two: by the lower semicircular shell 212, the magnetic roller 23 installed in the shell, the powder knife 26, and the buckles 29, 31 installed on the two ends of the shell form the powder feeding parts, such as figure 2 (B) shown. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com