Injector system for combustion engines operated on fuel, in particular heavy oil

A technology of injection system and internal combustion engine, which is applied in the direction of fuel injection device, charging system, liquid fuel feeder, etc., and can solve problems such as damaged operation and failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

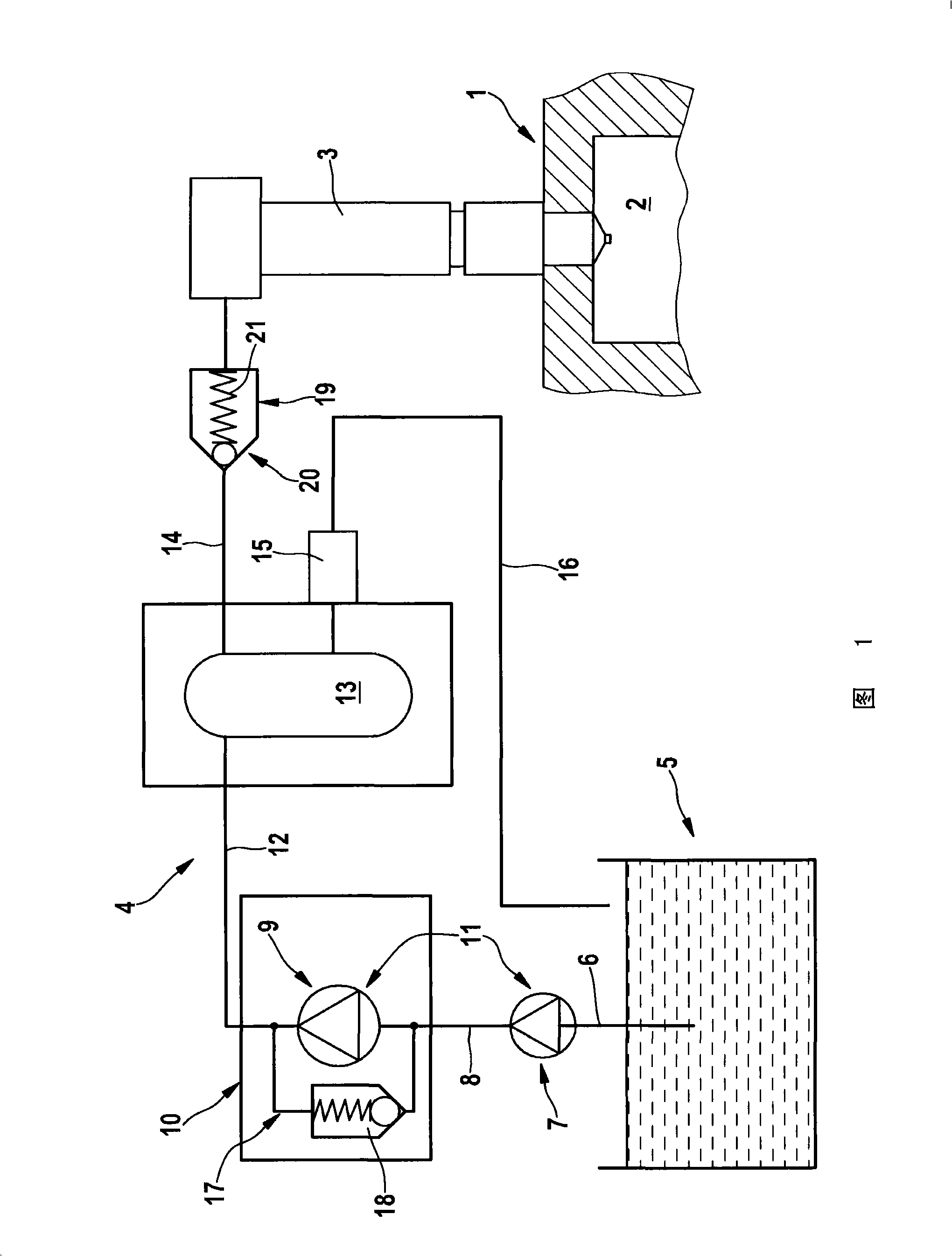

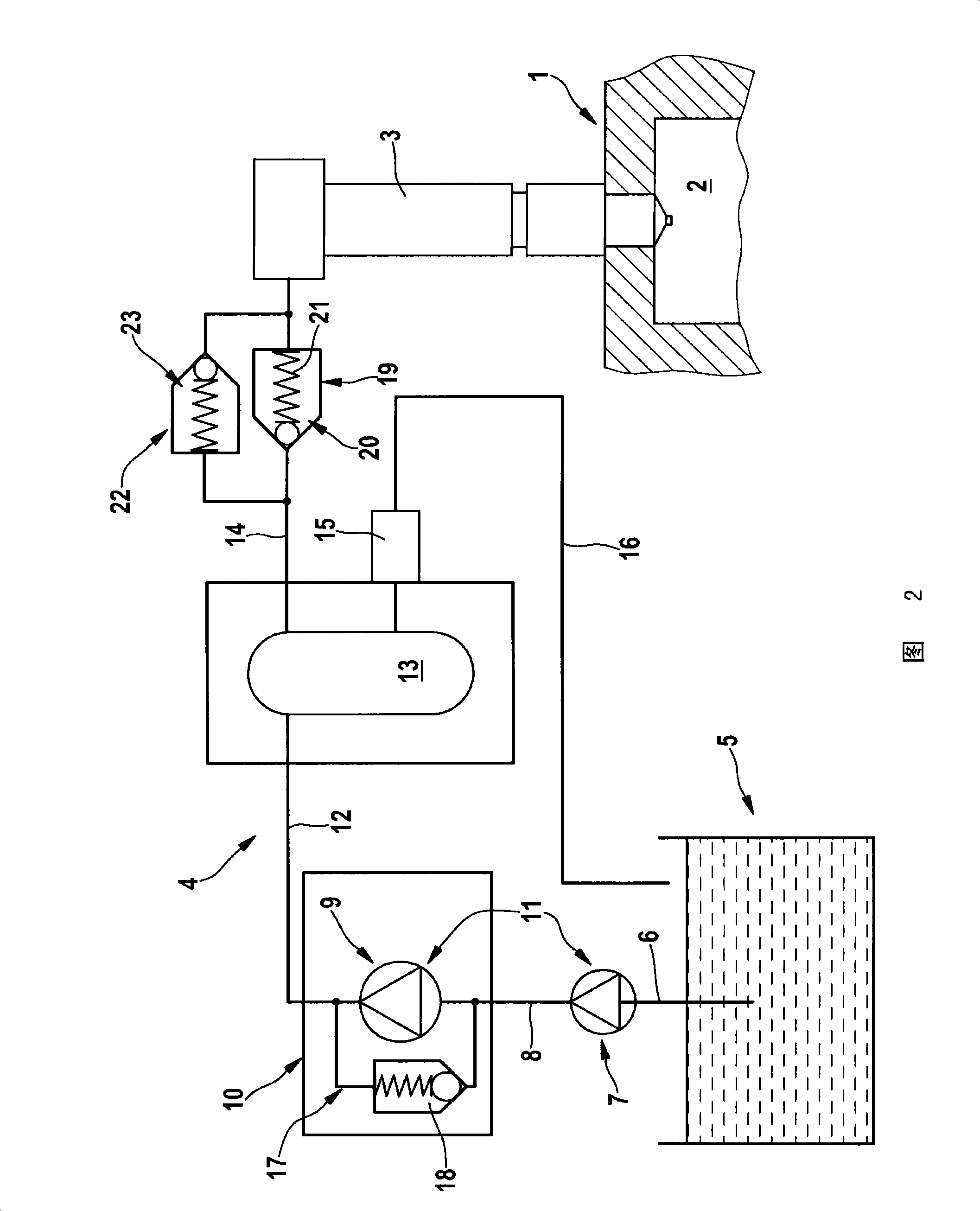

[0016] In view of the fact that the injection systems shown in the schematic views have the same structure in principle, the same reference numerals are used for the same components in the description of FIGS. 1 and 2, where 1 is the internal combustion engine, and only is shown Part of the combustion chamber 2 with one cylinder. Generally, the internal combustion engine 1 is of a multi-cylinder structure and is provided with a corresponding number of injectors 3 similarly to the injectors 3 injected into the combustion chamber 2, which are connected in parallel with the injectors 3 shown here to the overall designation 4 In the injection system.

[0017] The injection system 4 shows its most important elements and starts with a fuel tank 5 for heavy oil set as fuel, including a pre-delivery pump 7 sucked from the fuel tank 5 through a duct 6 as a low-pressure source, and it is connected to a low-pressure source through a duct 8 The high-pressure pump 9 of the high-pressure unit 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com