Structure for connecting ends of two strips

A technology with ends and edges, applied in the direction of connection members, hose connection devices, applications, etc., can solve problems such as damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

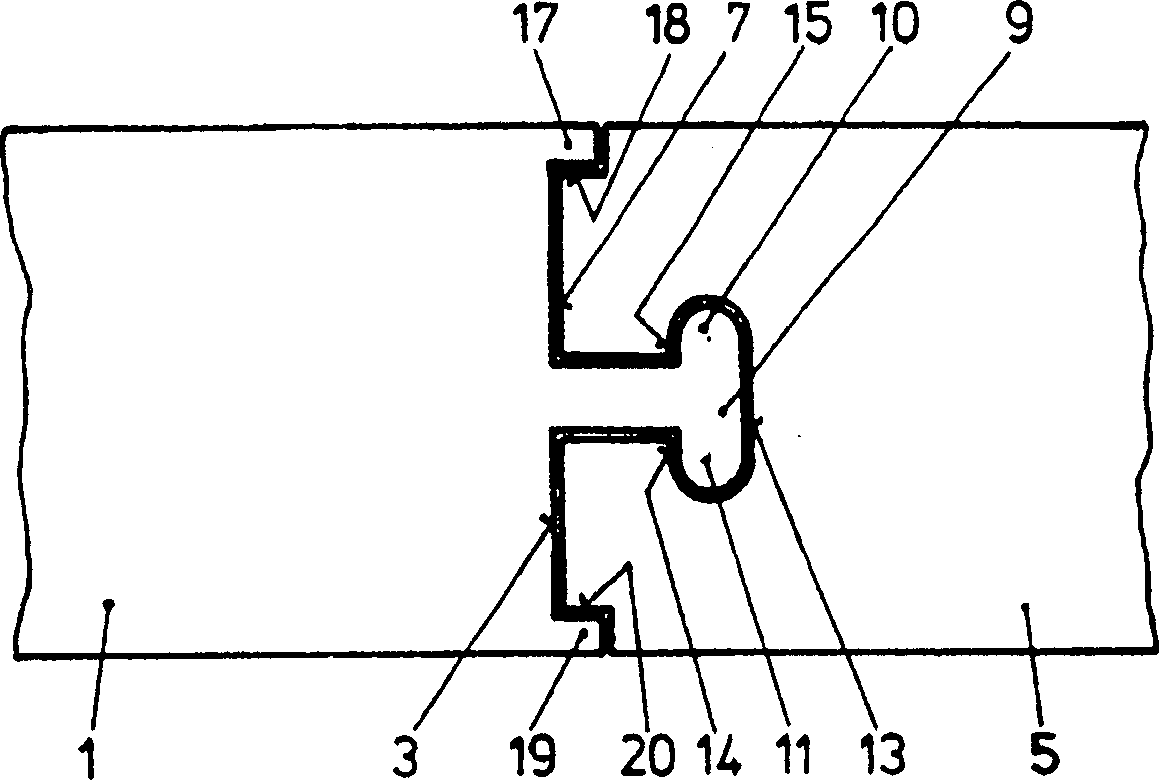

[0027] figure 1 A possible embodiment of a connection of two strips known from the prior art, eg suitable for latching a tubular clamp, is shown. The two end segments 1 and 5 of the strip are connected to each other along their common edge 3 or 7 . A stop or projection or tongue 9 is provided on one side 3, which comprises a fishtail-shaped part protruding laterally. This protrusion or tongue 9 consists of two such fishplates 10 and 11, wherein the tongue engages with the two fishplates in corresponding congruent grooves in the belt segment 5, which for the sake of simplicity No longer marked with a reference number. The tongue or projection 9 engages with the aid of the two fishplates or parts 10 and 11 from behind along the two parts 14 and 15 , viewed in the direction of the end edges, into a corresponding groove.

[0028] if figure 1 If the shown connection is stretched or upset, then the portion of the strip 5 behind the parts 14 and 15 will tend to come off from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com