Coupling hook particularly for the lower arms of a three-point linkage of a tractor

A tractor and coupling ball technology, applied in the field of coupling hooks, can solve the problems of easy to use and sacrifice reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

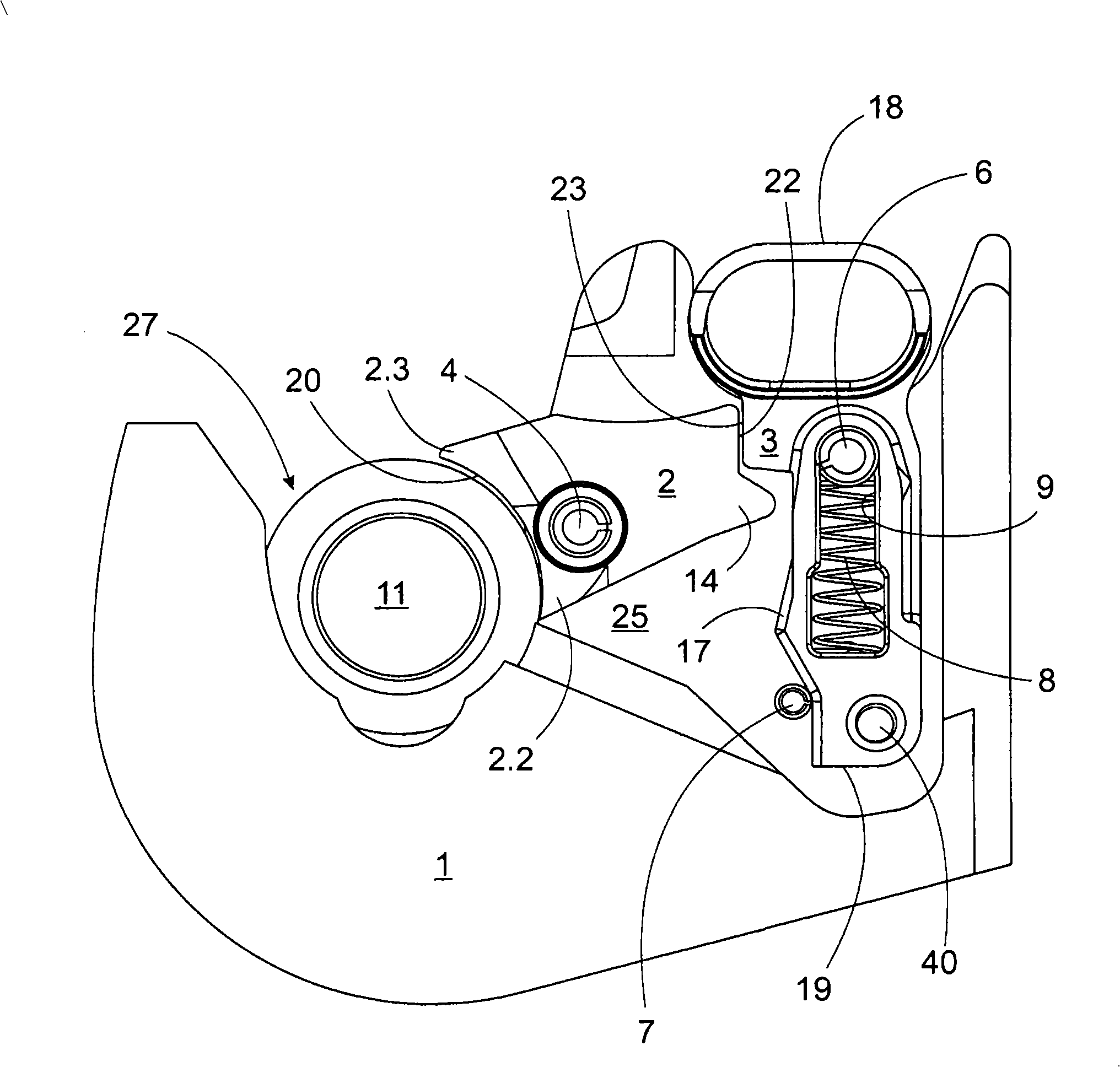

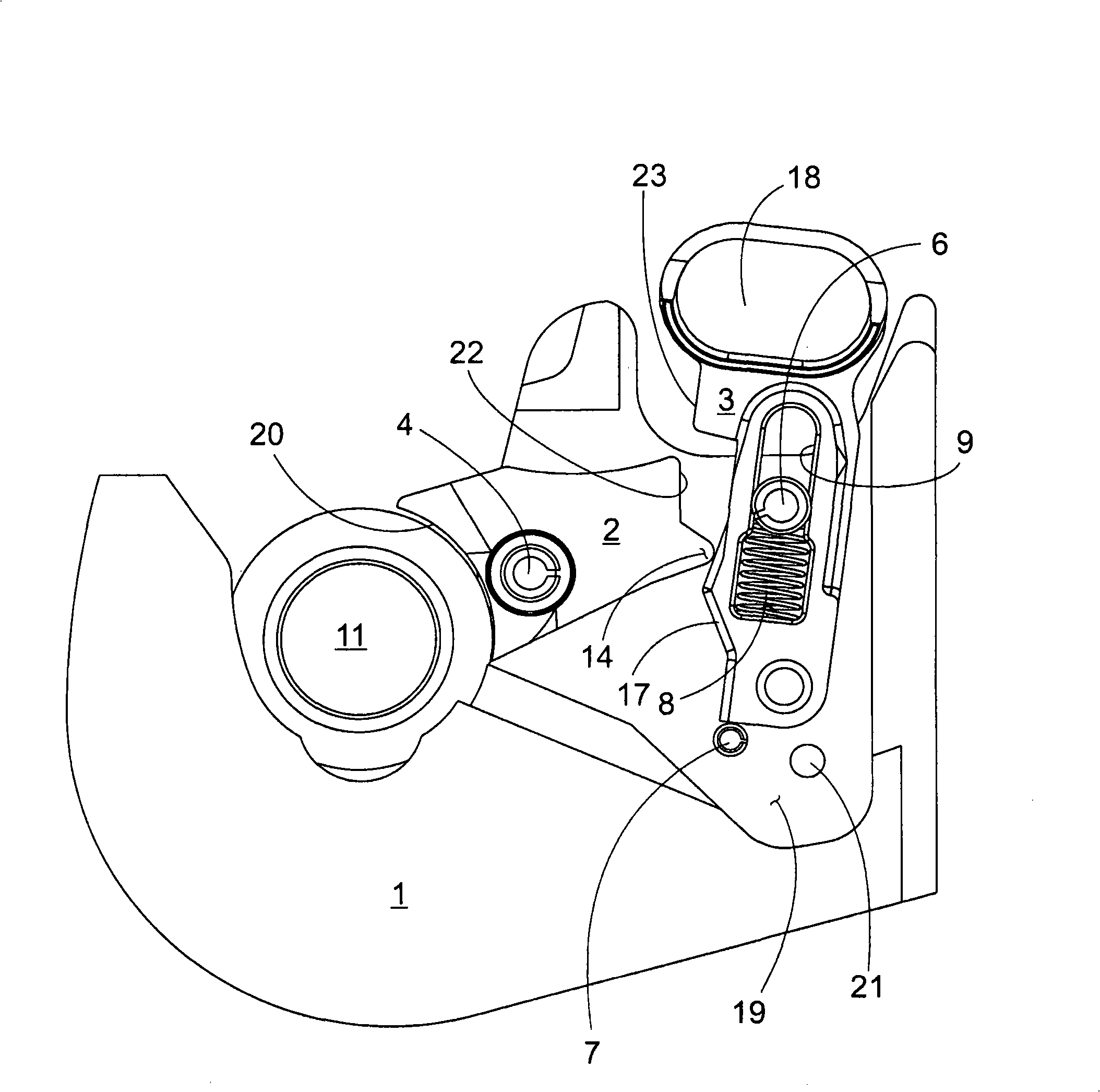

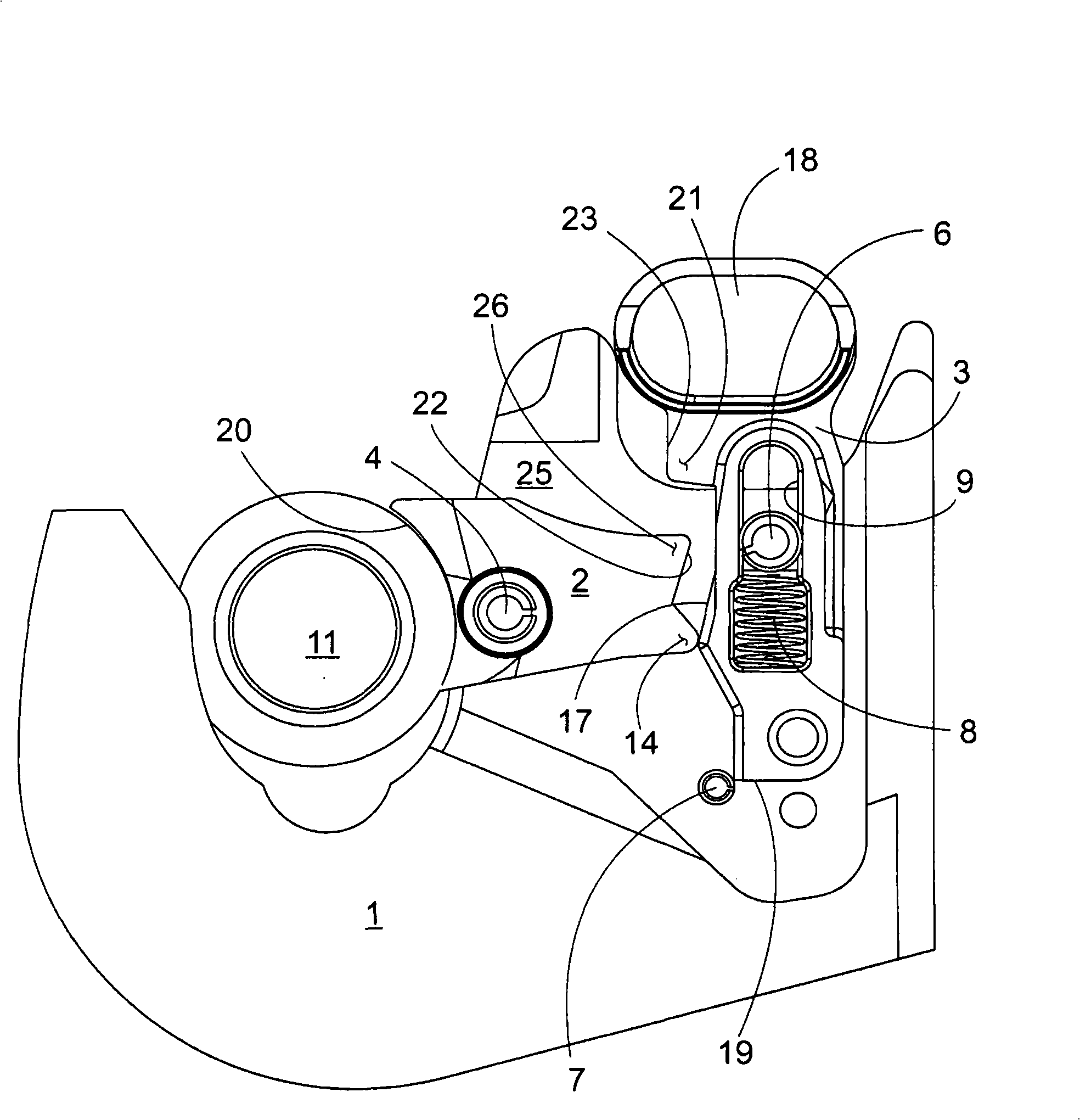

[0017] In the figures, the coupling hook according to the invention is shown without a cover, which is welded to the coupling hook in the final product. Also, coupling hooks (category 3, ISO 11001) shown slightly smaller than actual size.

[0018] The coupling hook itself is also attached to the lower arm by welding. The coupling hook comprises a main body 1 with a coupling throat 27 and a housing 25, see Figure 1a . The operating mechanism of the pawl 2 is mainly located in the housing 25 . The coupling throat 27 is conventional, which is notably arranged to receive the coupling ball 11 . The coupling ball 11 is usually permanently mounted in the appliance, or mounted to a conventional three-point coupling pin. Also, quick coupling is possible even without coupling balls, but this is not recommended. In addition, possible small angular differences between the pin and the lower arm can be eliminated by means of the coupling ball. In the figures, the coupling ball is mark...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com