Distilling device suitable for globular distillation flask

A technology for distillation flasks and distillation equipment, which is applied in the direction of flasks, distillation separation, still racks/fixtures, etc. It can solve problems such as inaccurate positioning and alignment, and distillation features that cannot meet the requirements, so as to improve efficiency and ensure quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

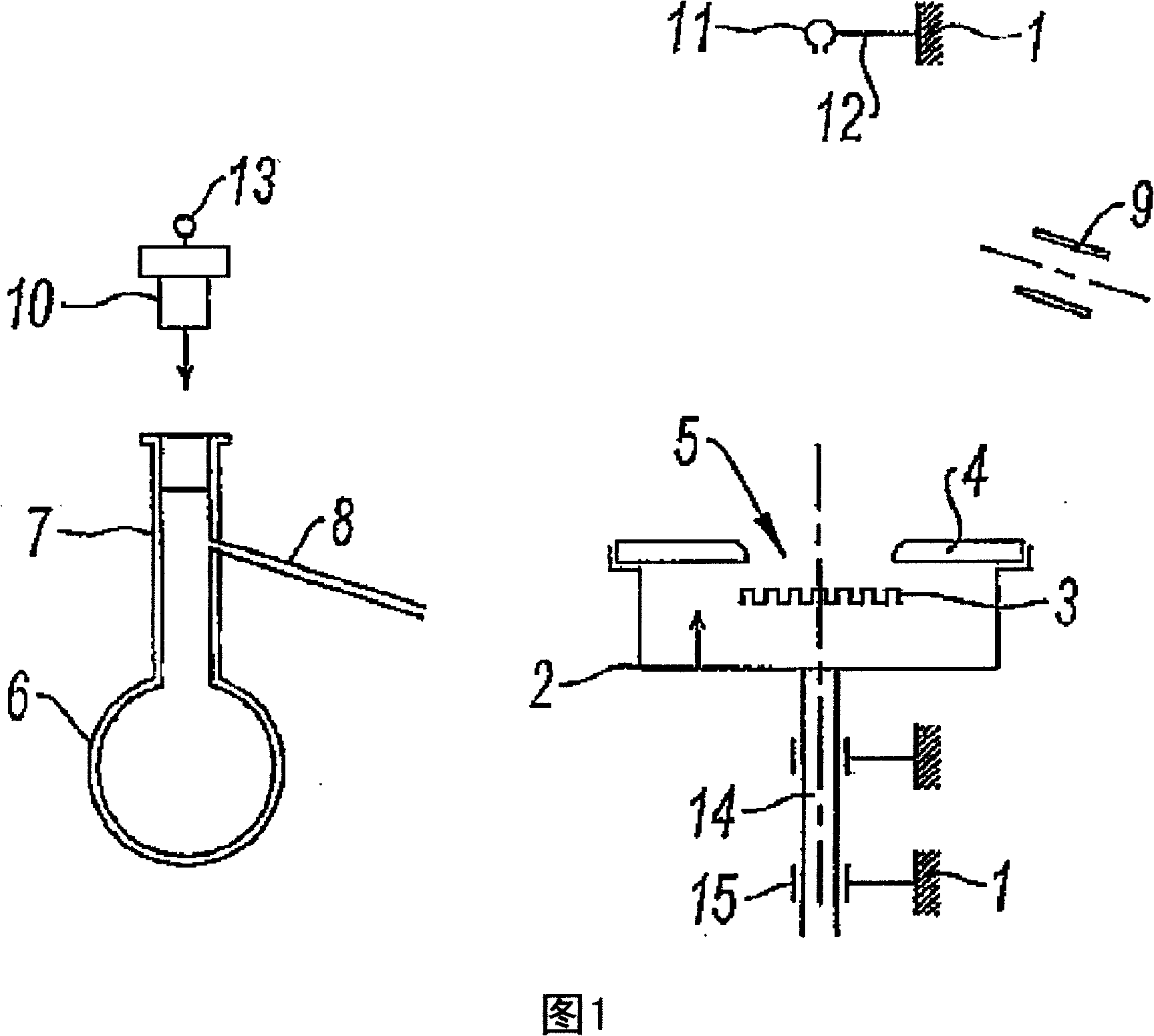

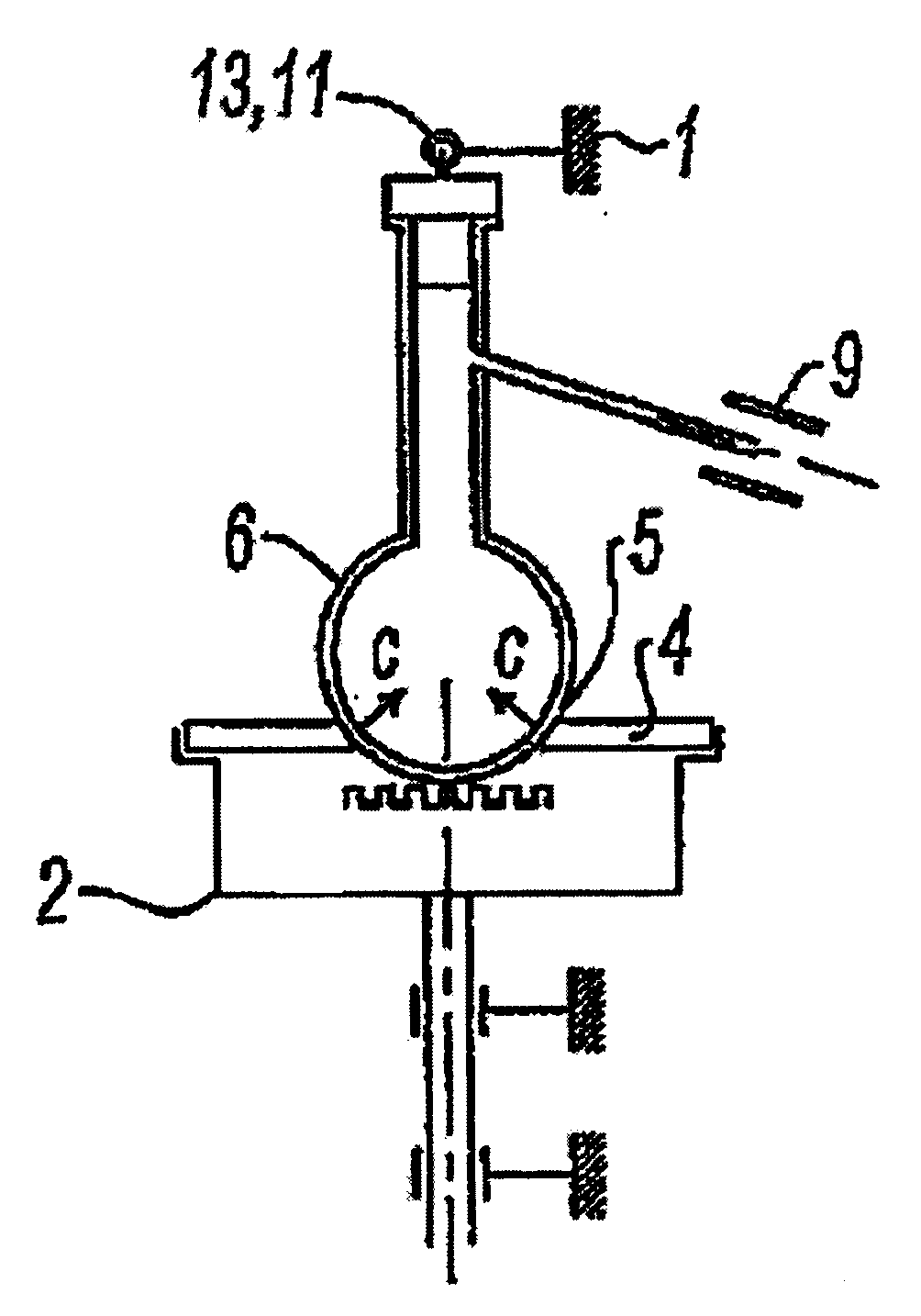

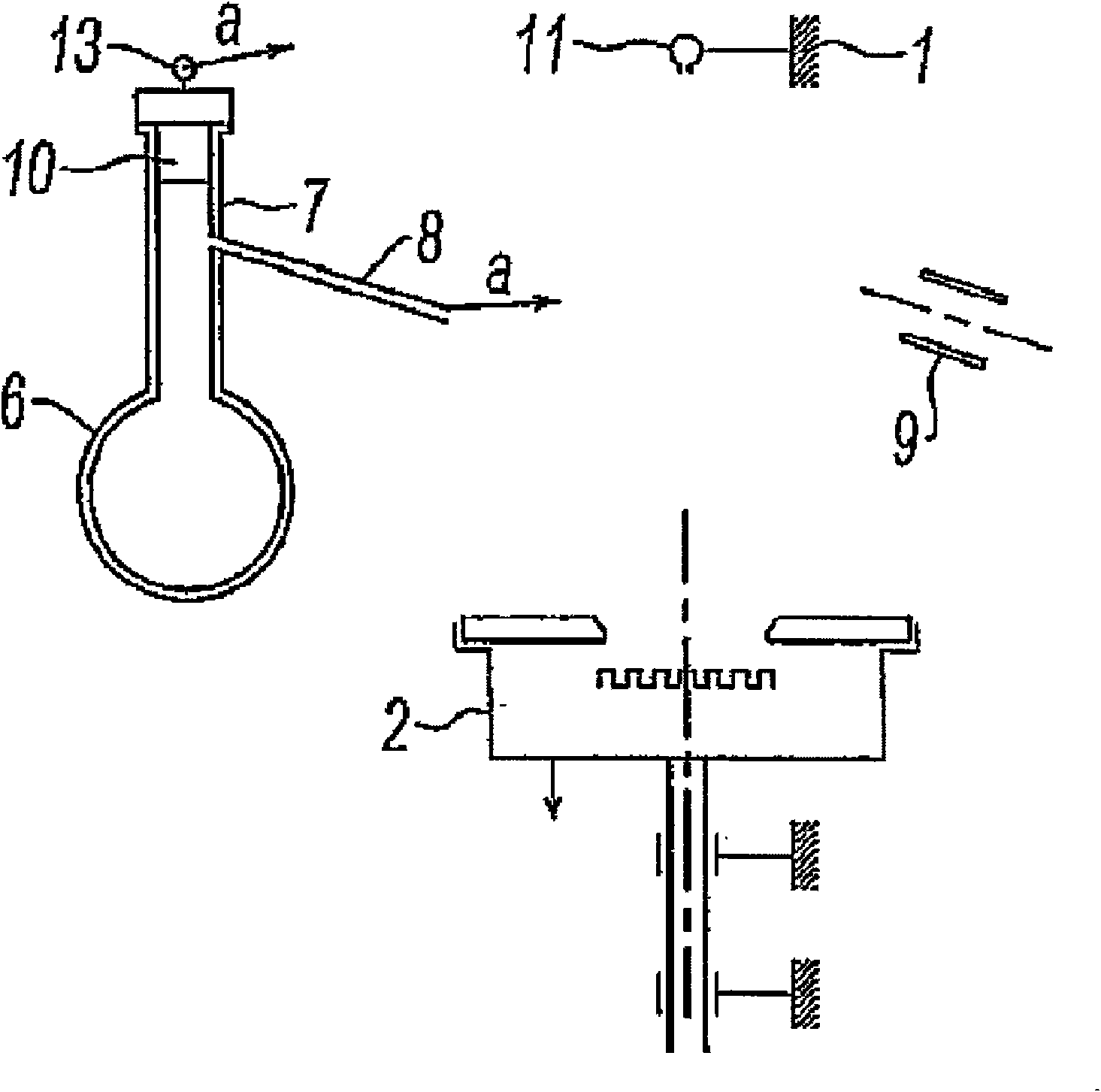

[0024] like figure 1 As shown, the distillation apparatus comprises a frame on which a heating wall 2 is mounted. This heating wall includes a heating element 3 and is closed at its upper part by an insulating panel 4 .

[0025] Said insulating plate 4 is provided with a central opening 5 for receiving the bottom of a spherical distillation flask 6 . The column opening 7 of the spherical distillation flask comprises a transverse branch 8 for connection to a condenser tube 9 . The condenser tube 9 is connected to the frame 1 of the distillation apparatus (in figure 1 Only its only free end is shown in ).

[0026] The tightly closed bottle stopper 10 can seal the post mouth 7 of the spherical distillation flask 6 at the top of the post mouth.

[0027] The frame 1 of the distillation equipment also includes a support 12, and a hinged limit block 11 is arranged at the terminal end of the support 12, and the limit block and the support 12 are integrally installed on the frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com