Vibrocompacting device

A technology of molding machine and vibrating table, which is applied in the direction of presses, material forming presses, manufacturing tools, etc., and can solve problems such as difficult to determine and narrow working range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

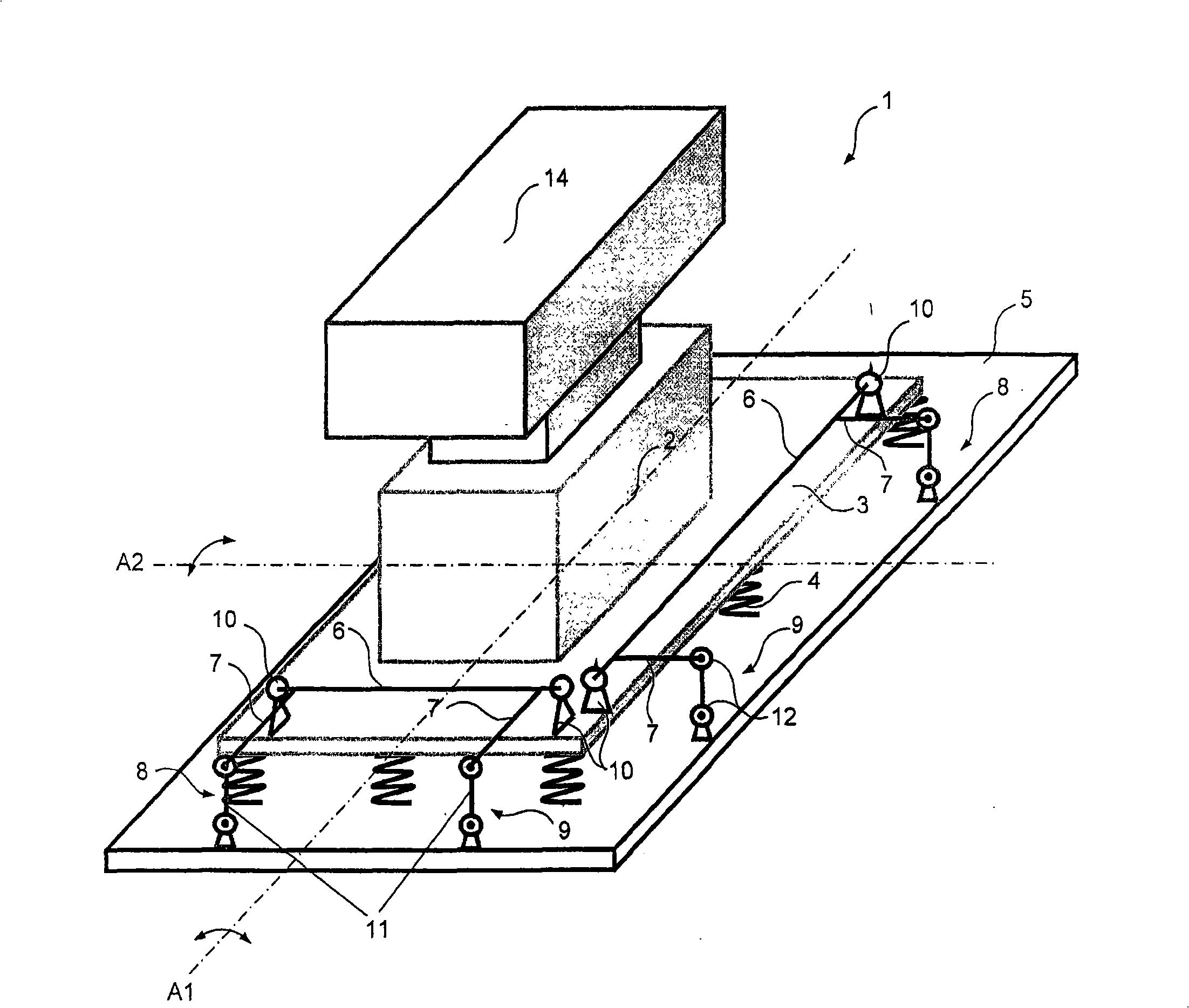

[0016] The present invention relates to a vibratory forming machine, in particular for forming molded anode blocks.

[0017] The press comprises at least one mold 2 supported directly or indirectly by a vibrating table 3 . The mold can be configured to be integrated with the vibrating table, or it can be configured to be moved and simply placed on the vibrating table.

[0018] The vibrating table 3 is fixed to the base frame 5 through the suspension device 4, and is configured to move in a vertical direction under the action of a vibration excitation device.

[0019] The term "pedestal" should be understood broadly, which may be a load-bearing structure made of metal or concrete, or the ground.

[0020] The suspension means are elastic buffer means, especially in the form of pneumatic means, such as inflatable cushions, or they may simply consist of helical springs.

[0021] The vibration excitation device may consist of a (not shown) vibration machine (unbalance device). T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com