Liquid ejecting head and liquid ejecting apparatus

A liquid jet head, liquid technology, applied in printing and other directions, can solve the problems of increased operating costs, user burden, frequent replacement of ink cartridges, etc., to achieve the effect of suppressing adverse effects and reducing flying bending

Inactive Publication Date: 2010-11-10

SEIKO EPSON CORP

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In addition, if the ink in the ink cartridge is consumed quickly, the ink cartridge needs to be replaced frequently, thereby increasing the burden on the user in terms of running costs, and there are also problems from the viewpoint of environmental protection.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

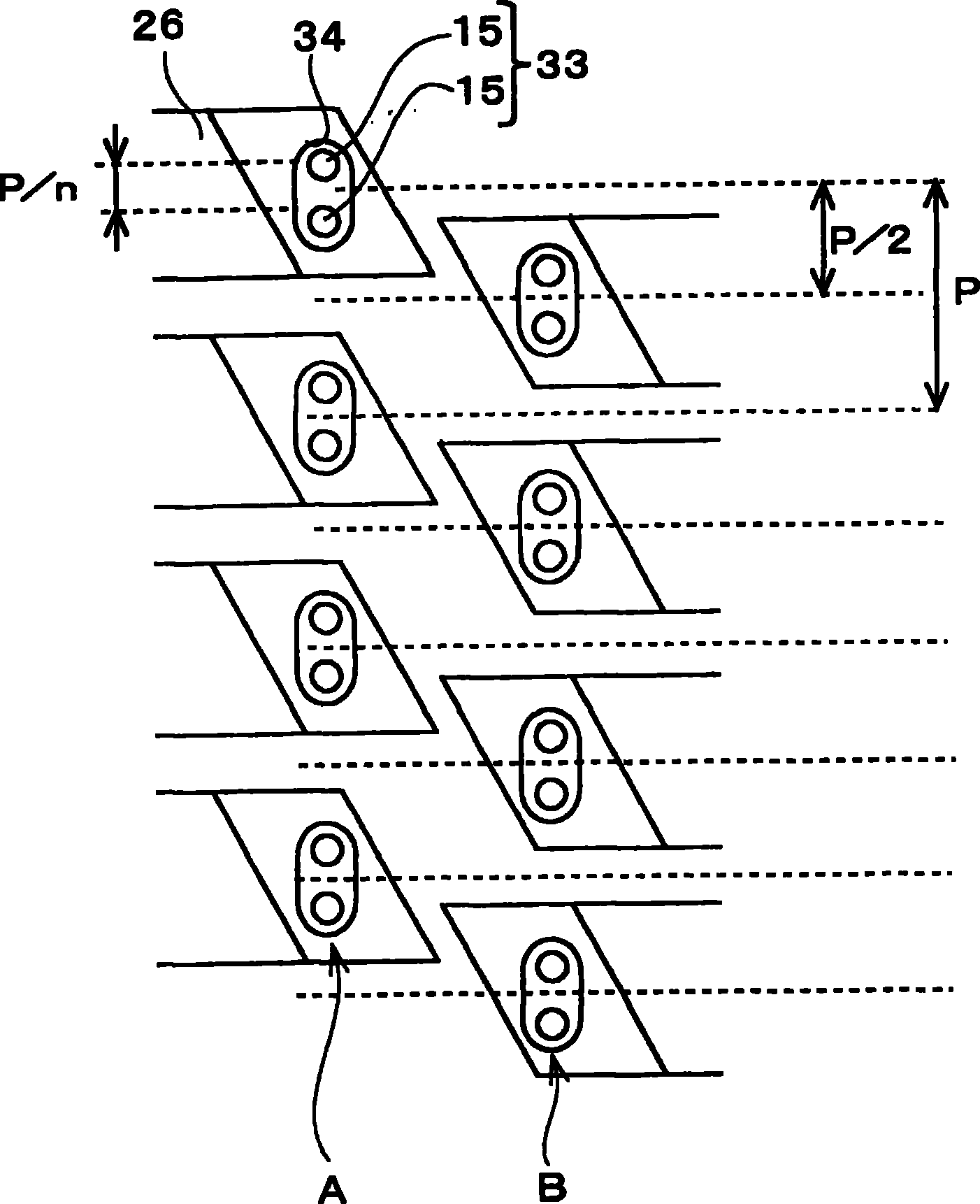

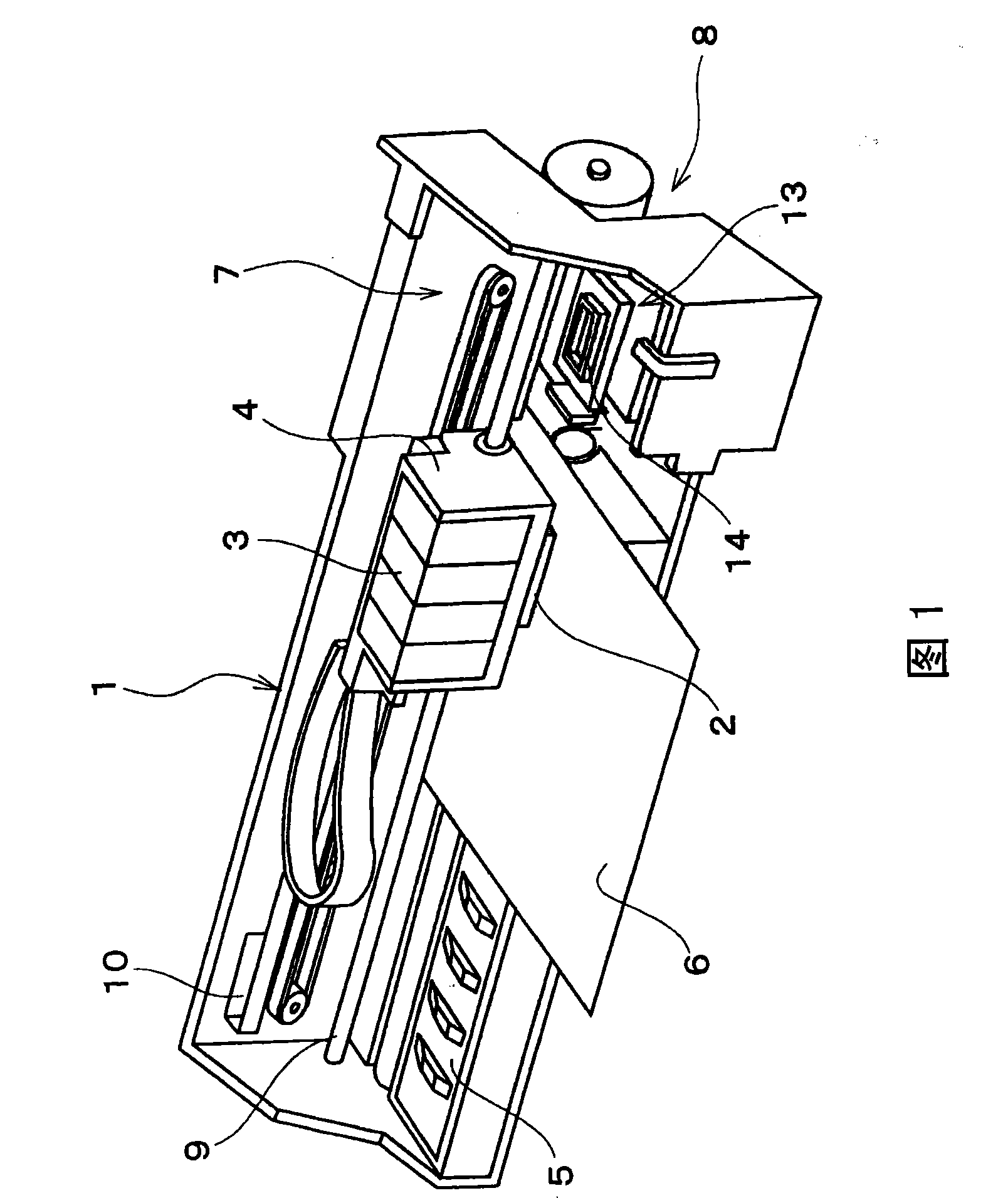

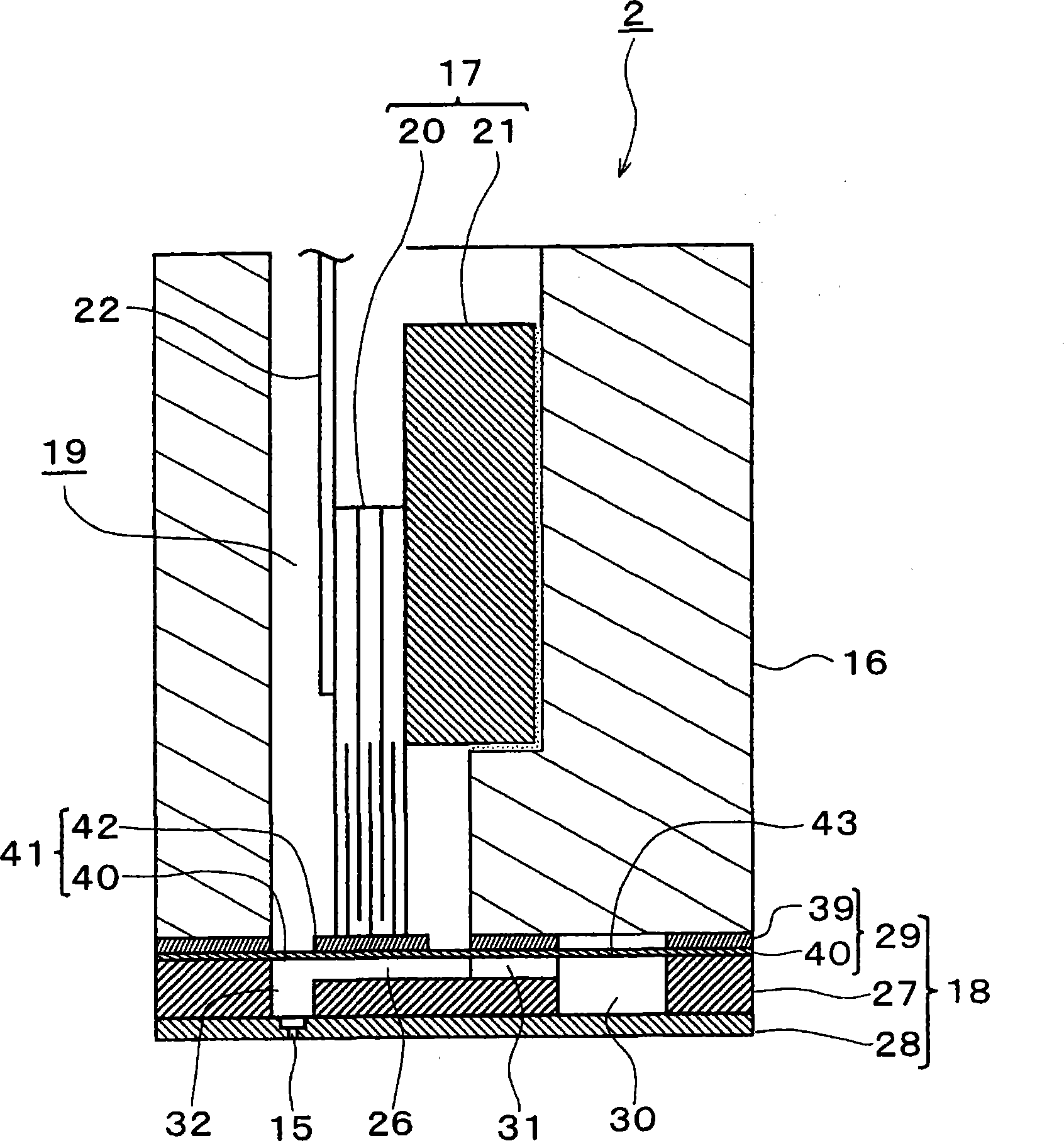

A liquid ejecting head includes a plurality of nozzle groups each including a plurality of nozzle openings; and a plurality of pressure generating chambers that cause liquid to be ejected from the nozzle openings. A plurality of recessed portions are formed at a nozzle forming member, the recessed portions each having a thickness smaller than a thickness of the nozzle forming member, the nozzle openings being formed at the recessed portions. A set of at least one of the plurality of nozzle openings included in each single nozzle group defines a nozzle set, the nozzle set being arranged to correspond to each of the pressure generating chambers. The nozzle groups each have a plurality of nozzle sets in an array, the nozzle sets of one of the nozzle groups being relatively shifted from the nozzle sets of another one of the nozzle groups in a nozzle-set-array direction.

Description

Liquid ejection head and liquid ejection device technical field The present invention relates to a liquid ejection head such as an inkjet recording head and a liquid ejection device, and more particularly to a liquid ejection device having a plurality of nozzle groups with nozzle openings arranged in a row and a pressure generating chamber communicating with the nozzle openings, wherein the pressure generating chamber is changed to a pressure generating chamber. A liquid ejection head that ejects liquid from a nozzle opening corresponding to the pressure generating chamber, and a liquid ejection device including the ejection head. Background technique A liquid ejecting device is a device that includes a liquid ejecting head capable of ejecting a liquid, and ejects various liquids from the liquid ejecting head. As a representative device of this liquid ejecting device, for example, there is an ink jet type recording head (hereinafter simply referred to as a recording head) ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B41J2/14B41J2/145B41J2/045B41J2/055

CPCB41J2002/14475

Inventor 细野聪赤羽富士男田中良一

Owner SEIKO EPSON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com