Straw mulching hydraulic flip plow

A hydraulic flipping and straw technology, applied to plows, agricultural machinery and implements, agriculture, etc., can solve the problems of machines not working normally, straw and weeds blocking, stacking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

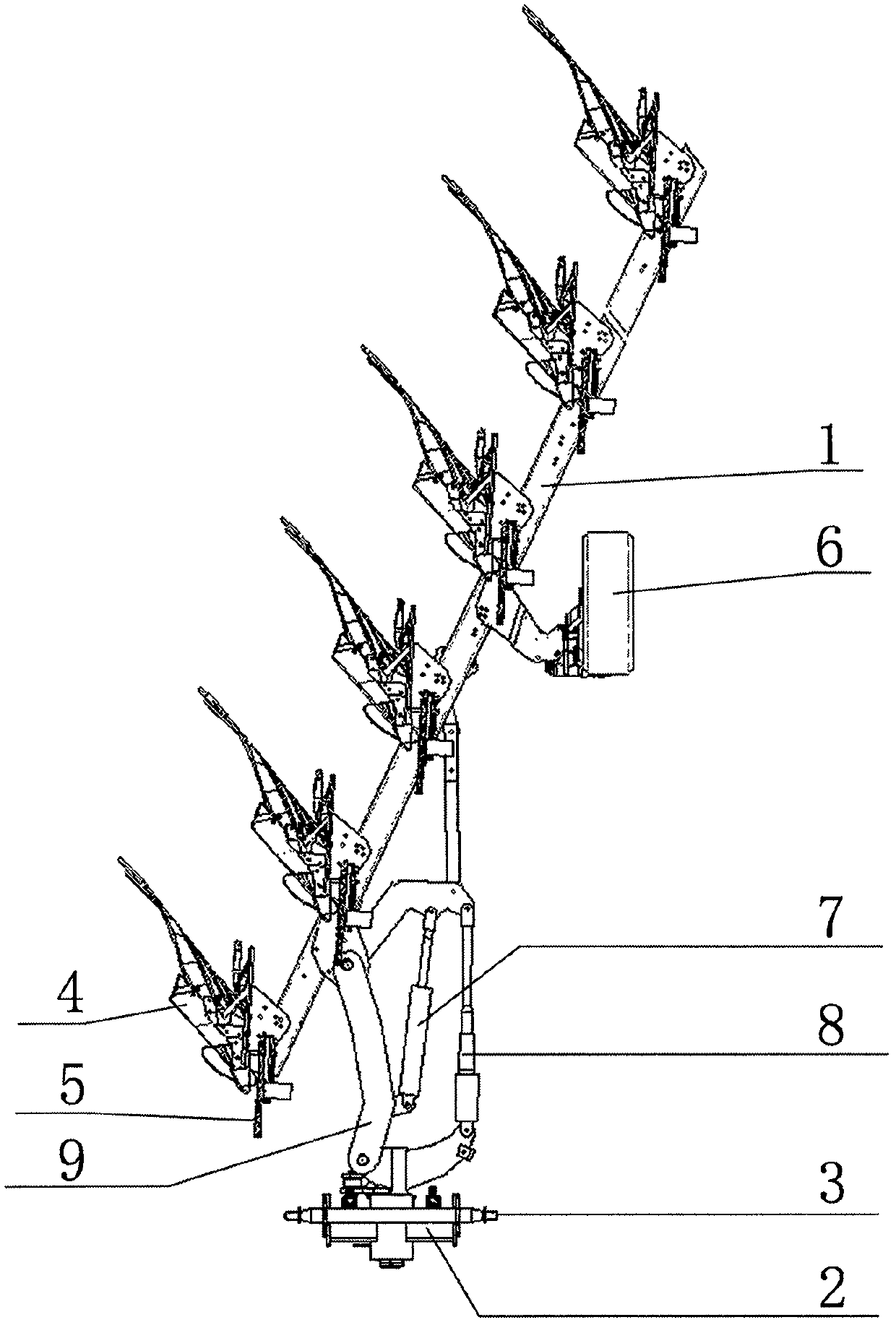

[0026] Such as figure 1 , Figure 7 , Figure 8 As shown, the suspension frame 2 is connected with the plow beam 1 through the H frame 9, the suspension shaft 3 connected with the tractor is arranged on the suspension frame 2, the reversing oil cylinder 23, the amplitude modulation oil cylinder A7, and the amplitude modulation oil cylinder B8 are respectively connected with the hydraulic output end of the tractor Plug and connect with the quick connector, and the depth-limiting ground wheel 6 is installed on the plow beam 1.

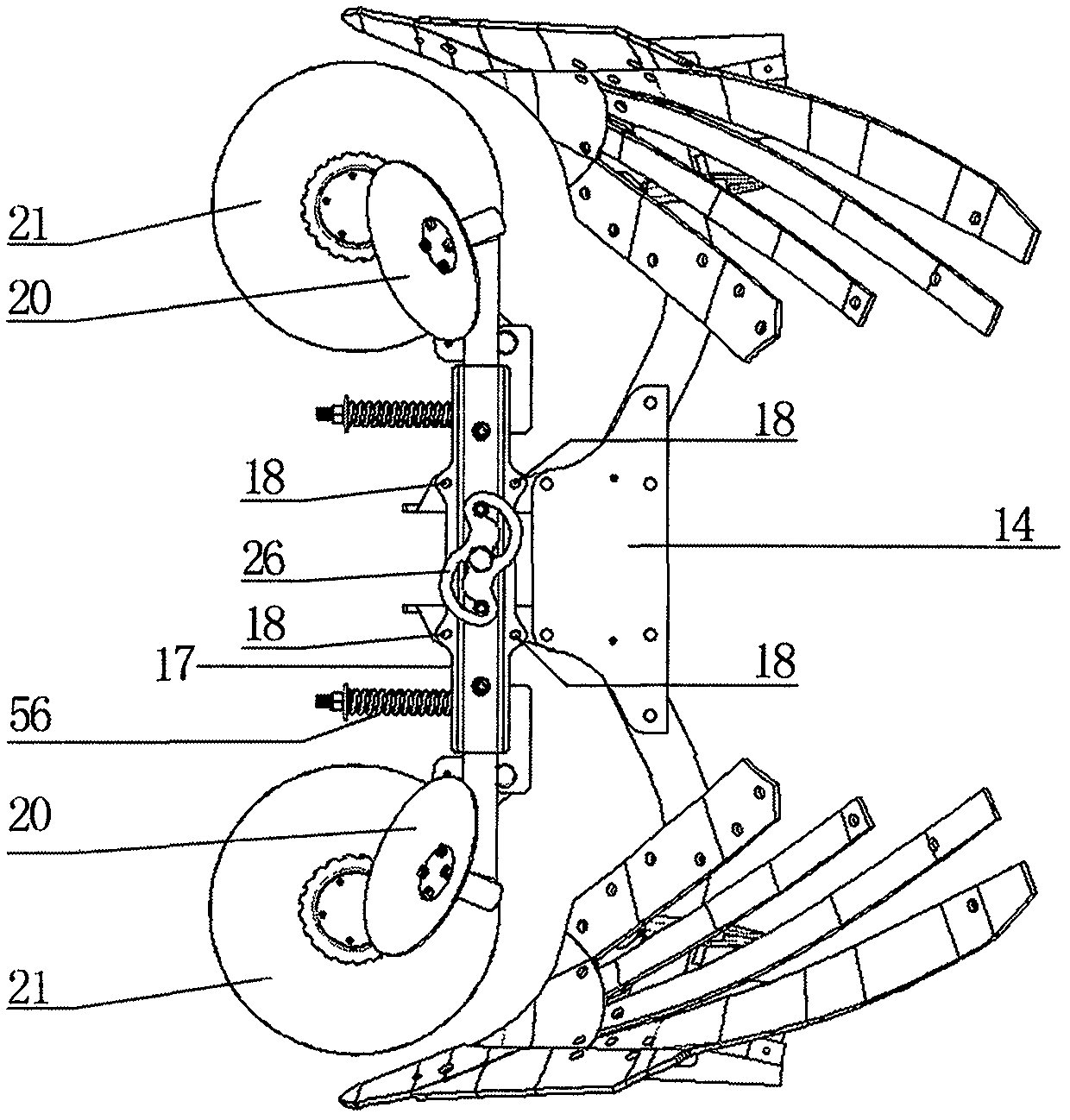

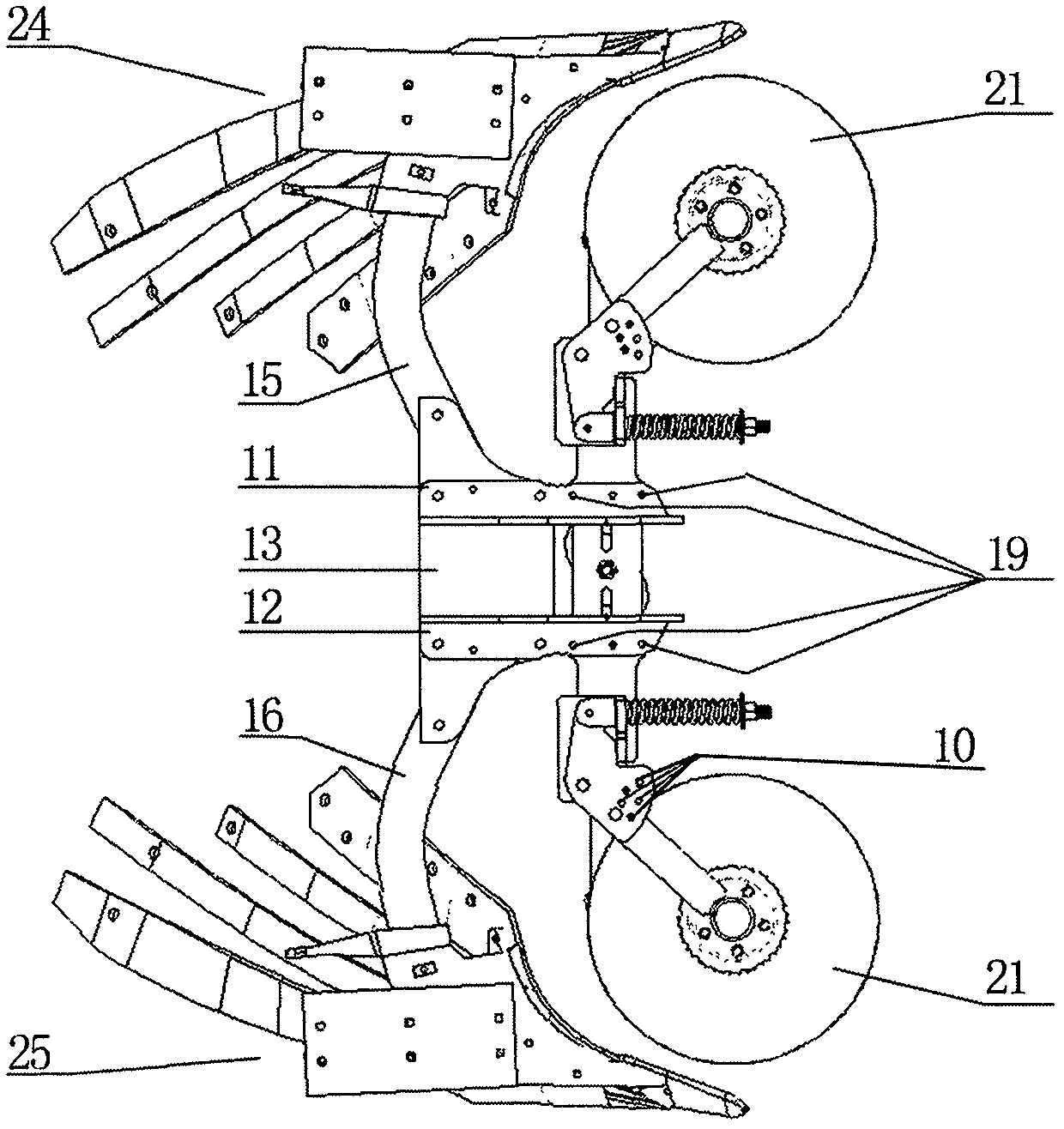

[0027] Such as Figure 7 , Figure 8 , figure 2 , image 3 As shown, multiple groups of main and auxiliary plow assemblies are arranged in an array on the plow beam 1, and each group of main and auxiliary plow assemblies is composed of a main plow assembly 4 and an auxiliary plow assembly 5, and the main plow assembly 4 And auxiliary plow assembly 5 is fixed through bolt connection.

[0028] Such as figure 2 , image 3 As shown, the main plow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com