Assembly scaffold

A scaffolding and combined technology, applied in the field of scaffolding, can solve the problems of inability to assemble and disassemble by a single person, and achieve the effects of reliable locking, simple locking and unlocking operations, and expanding the scope of application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

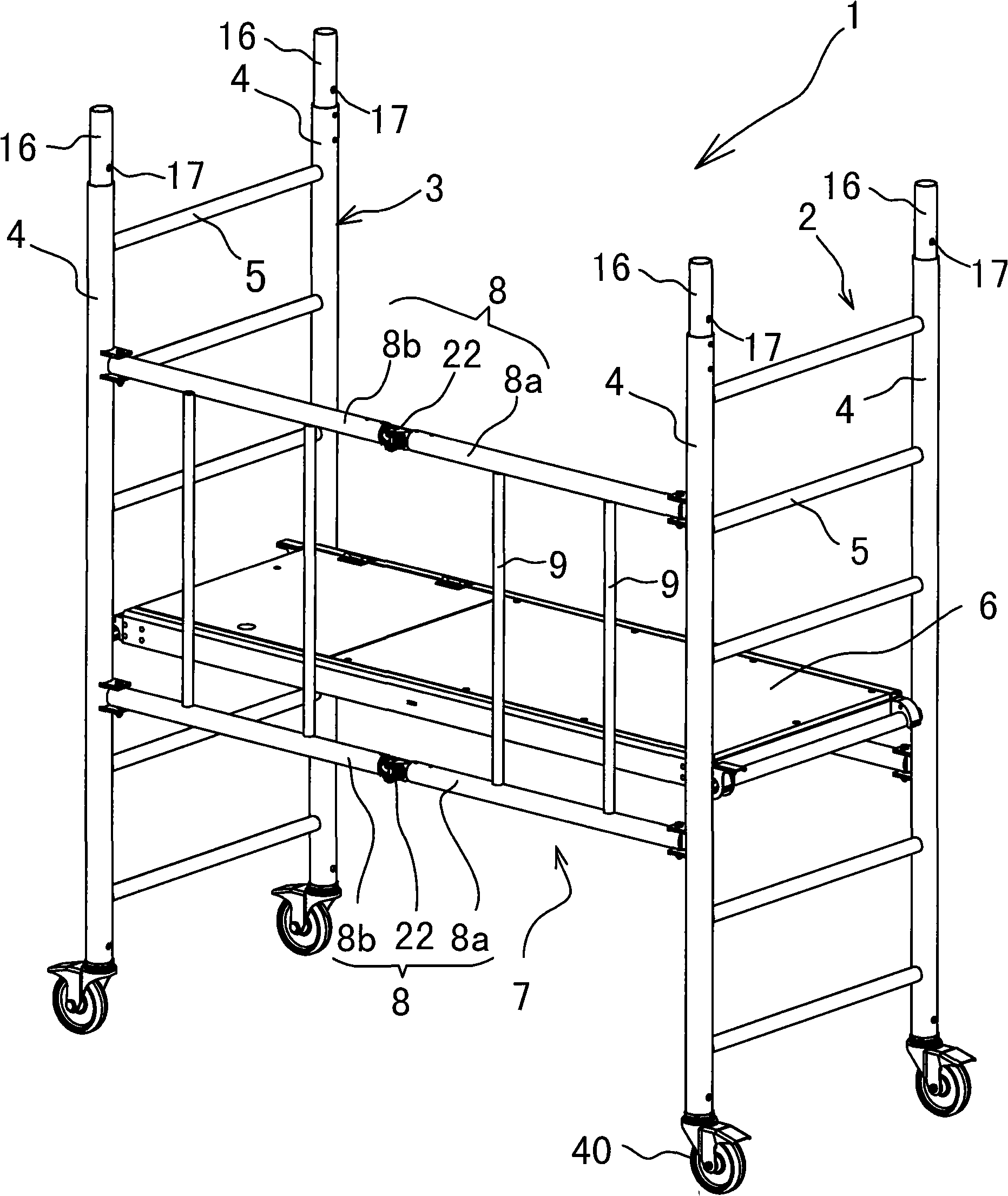

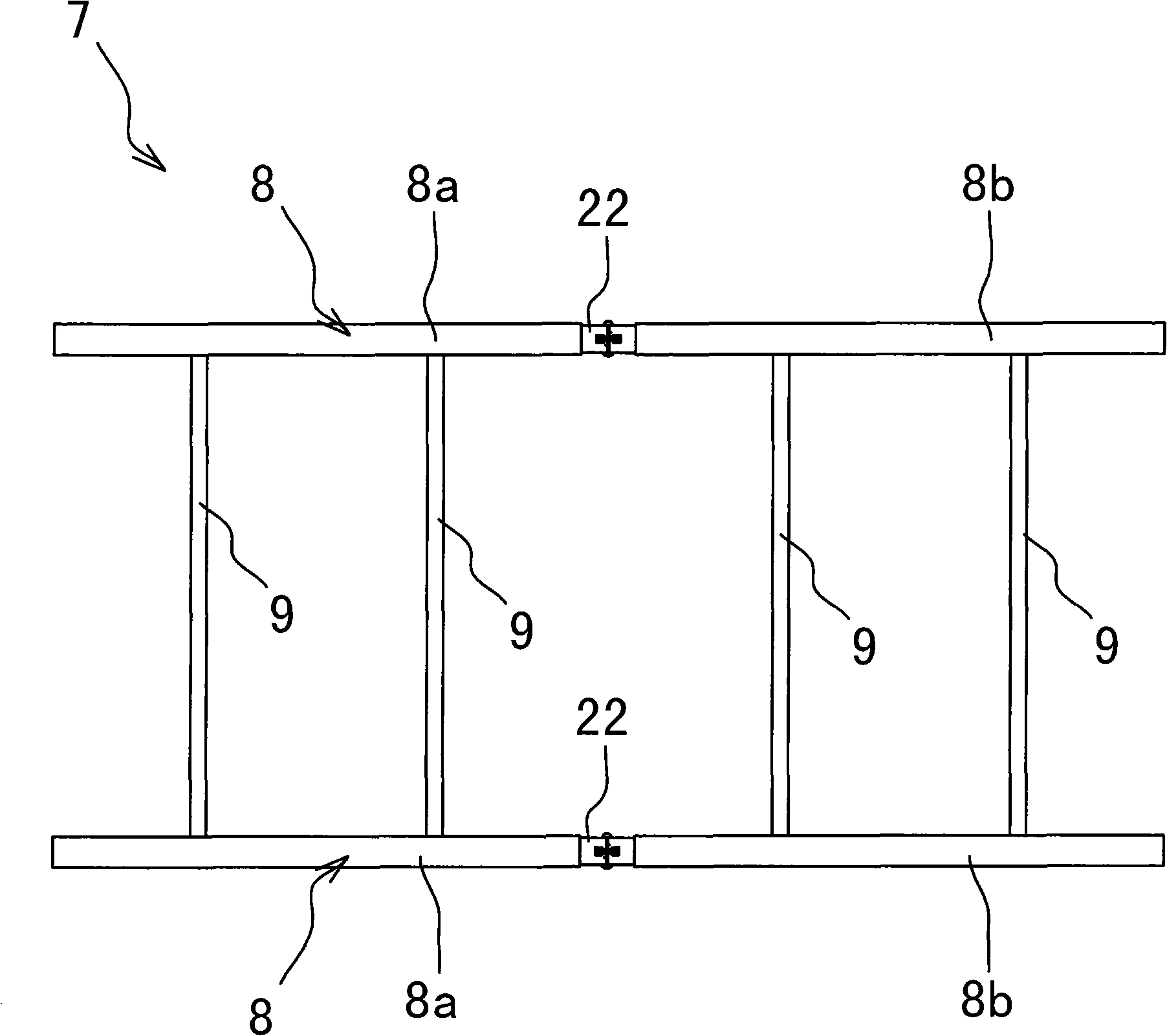

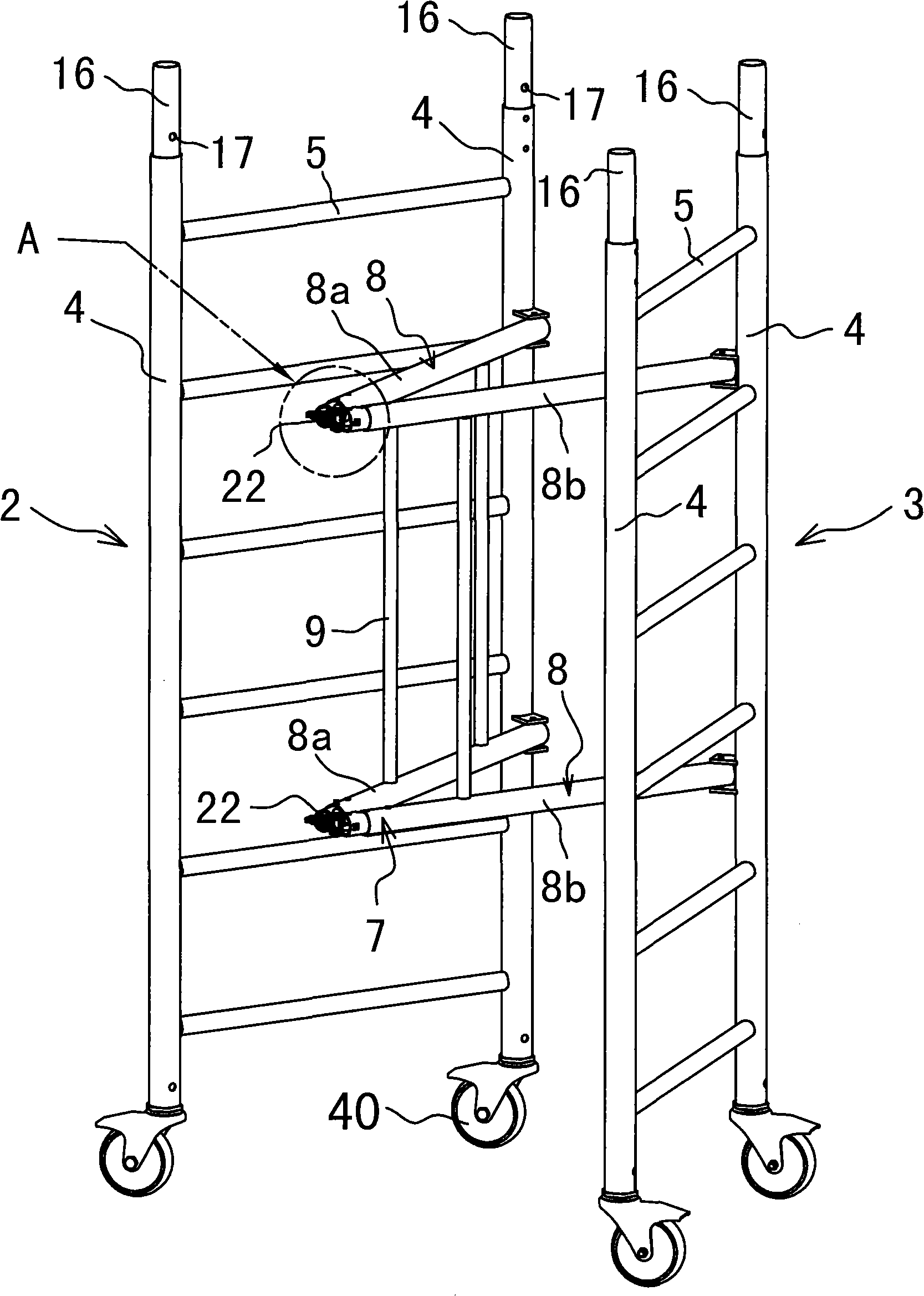

[0031] Embodiment one: see attached figure 1 ~ attached Figure 8 As shown, a combined scaffold, see attached figure 1 As shown, it consists of a bottom frame unit 1 with a working platform 6 erected. The bottom frame unit 1 has two side supports 2, 3 parallel to each other, and each side support 2, 3 is fixedly connected by a pair of columns 4 and Several parallel and evenly distributed pedal crosspieces 5 are formed between a pair of columns 4, and the two ends of the working platform 6 are respectively hooked on the opposite pedal crosspieces 5 on the two side supports 2 and 3 through two hooks. There is a folding frame 7 connected between a column 4 on the left side support 2 and the opposite same side column 4 on the right side support 3; figure 2 , the folding frame 7 is composed of two folding cross bars 8 and four longitudinal connecting rods 9 connected between the folding cross bars 8, and each folding cross bar 8 is composed of two sections of left and right cros...

Embodiment 2

[0038] Embodiment two: see attached Figure 9 ~ attached Figure 12 As shown, a combined scaffold differs from the first embodiment in that: it is based on the first embodiment to install a heightening frame unit 10, and the heightening frame unit 10 is as attached Figure 9 As shown, it is composed of two side brackets 11, 12 parallel to each other on the left and right, and a cross brace 13 and a diagonal brace 14 are overlapped. An embedding hole is provided, and an embedding end 16 is correspondingly provided on the top of the column 4 of the bottom frame unit 1. end 16, and the column embedded end 16 of the bottom frame unit 1 and the column 15 embedding hole of the heightened frame unit 1 are correspondingly provided with a through hole 17; see the attached Figure 9 As shown, there is a locking pin 18 consisting of a pin rod 19 and a semi-annular collar 20. The pin rod 19 penetrates the embedded end 16 and pins the through hole 17 on the embedded hole, and the tail en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com