Method for controlling torsion oscillator with preset frequency and generating steady vibration amplitude

A control method and technology of predetermined frequency, applied in the directions of instruments, installation, optics, etc., can solve the problems of narrowing scanning angle and application limitations, saving time for calculating resonance frequency, simplifying control methods, and reducing manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

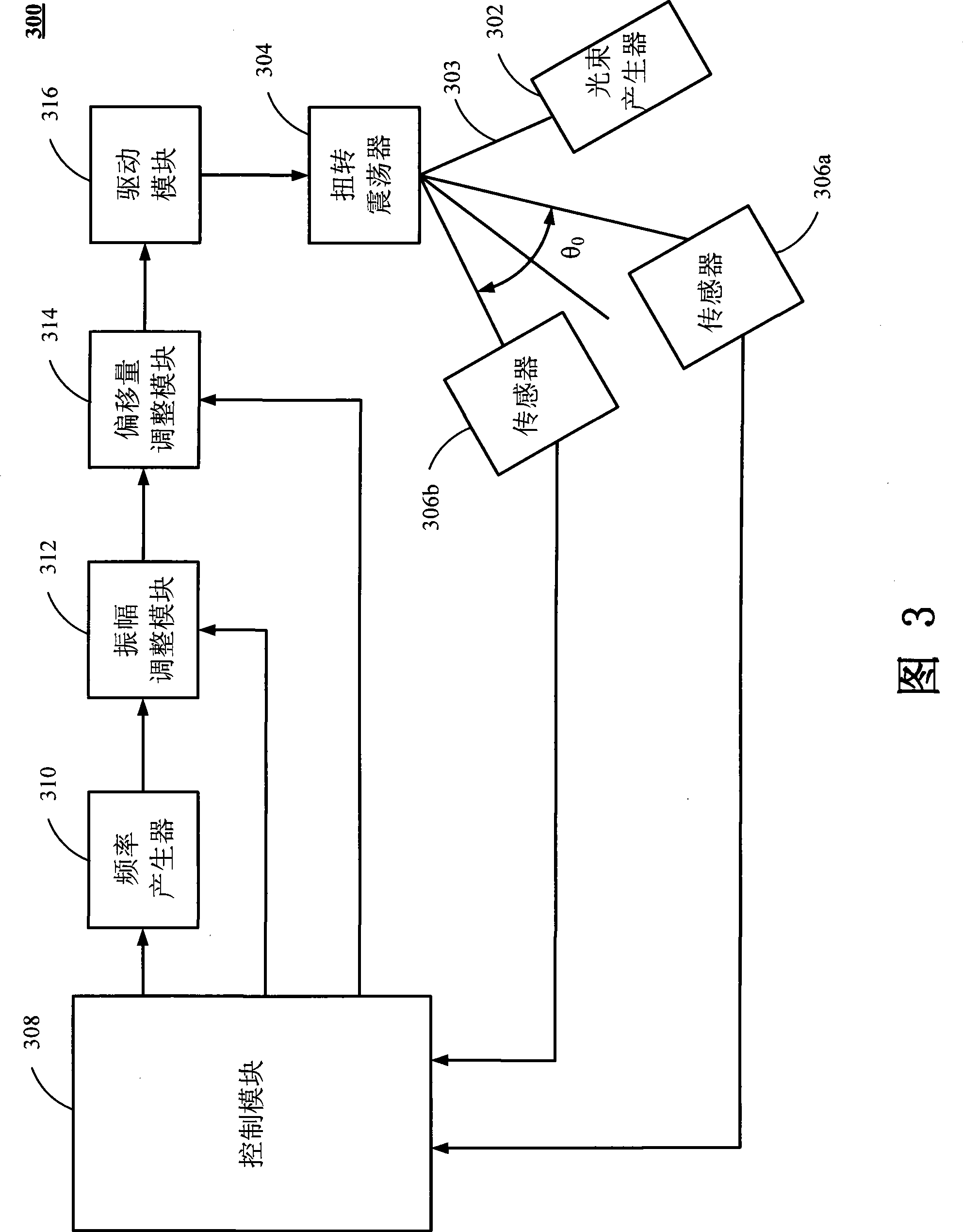

[0038] Please refer to image 3 , which is a schematic diagram of a control system of a torsional oscillator according to an embodiment of the present invention. The control system 300 is suitable for imaging devices, such as laser printers, copiers, fax machines, barcode scanners, laser projectors, laser radar and laser scanning sensors, etc. The control system 300 mainly includes a beam generator 302, a torsional oscillator 304, a sensor 306 , a control module 308 , a frequency generator 310 , an amplitude adjustment module 312 , an offset adjustment module 314 , and a drive module 316 . The beam generator 302 is, for example, a laser generator for generating the beam 303 . The torsional oscillator 304 is provided with a mirror (not shown), when a driving energy drives the mirror, the mirror rotates and reflects the light beam 303 to form a scanning angle θ 0 . The sensor 306 receives the reflected light beam from the torsional oscillator 304 and forms a sensing signal ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com