Packaging method for LED with high cooling efficiency and packaging structure thereof

A technology of light-emitting diodes and luminous effects, which is applied in the manufacture of electrical components, electric solid devices, semiconductor/solid-state devices, etc., can solve problems such as inconvenience, the inability to obtain heat dissipation effect of light-emitting diode chips D, and burnout of light-emitting diode chips D, etc., to achieve The effect of shortening the process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

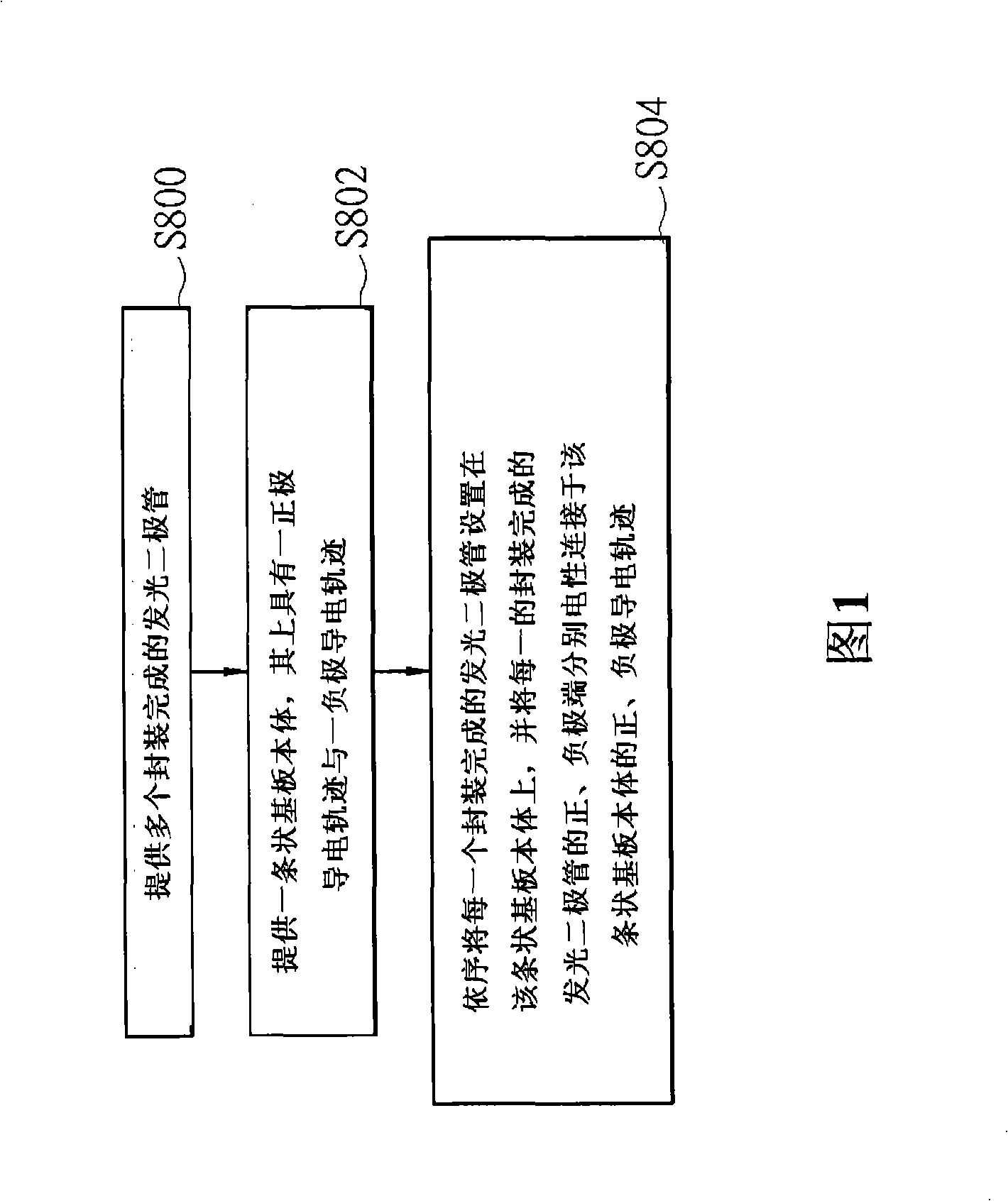

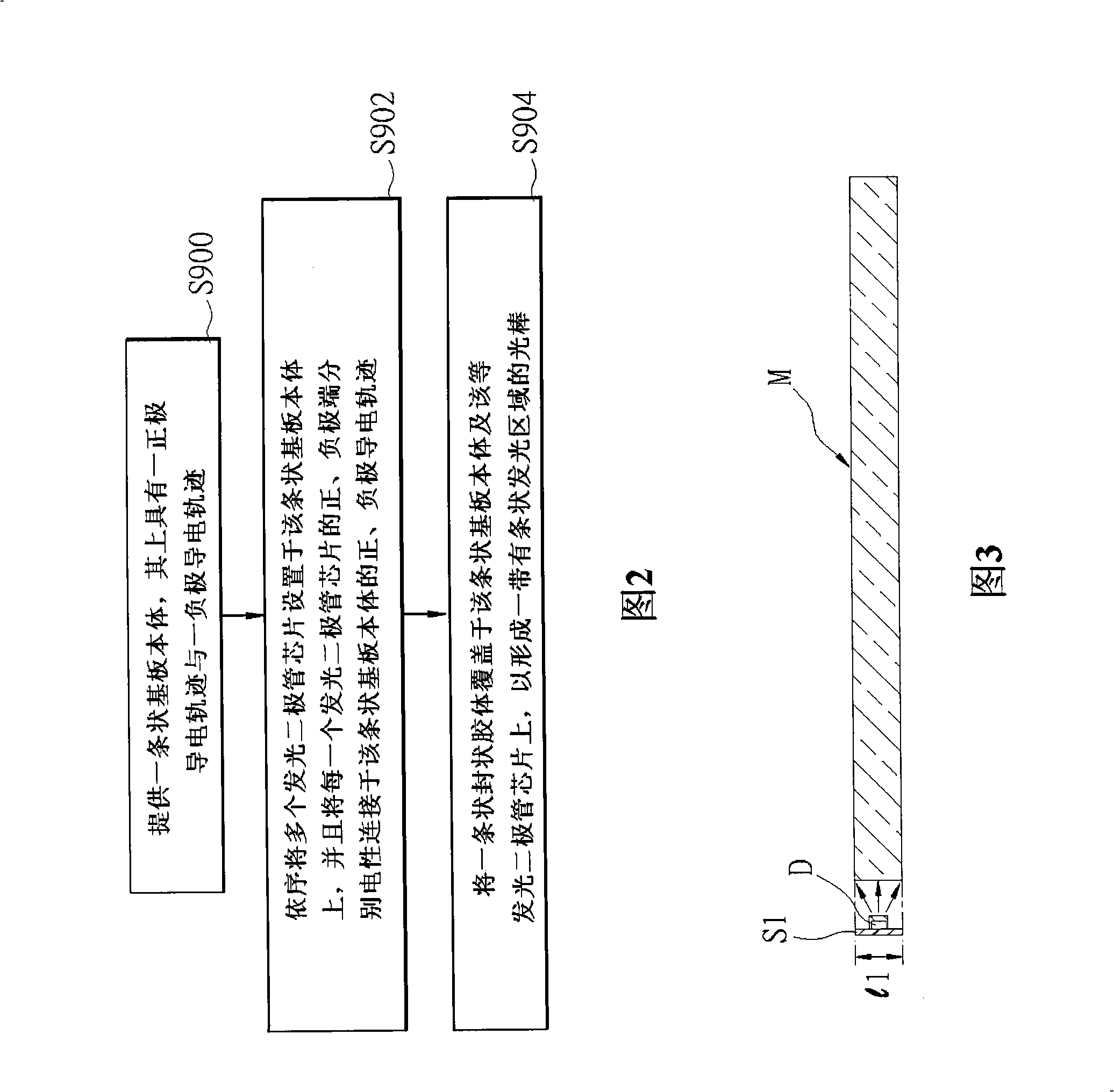

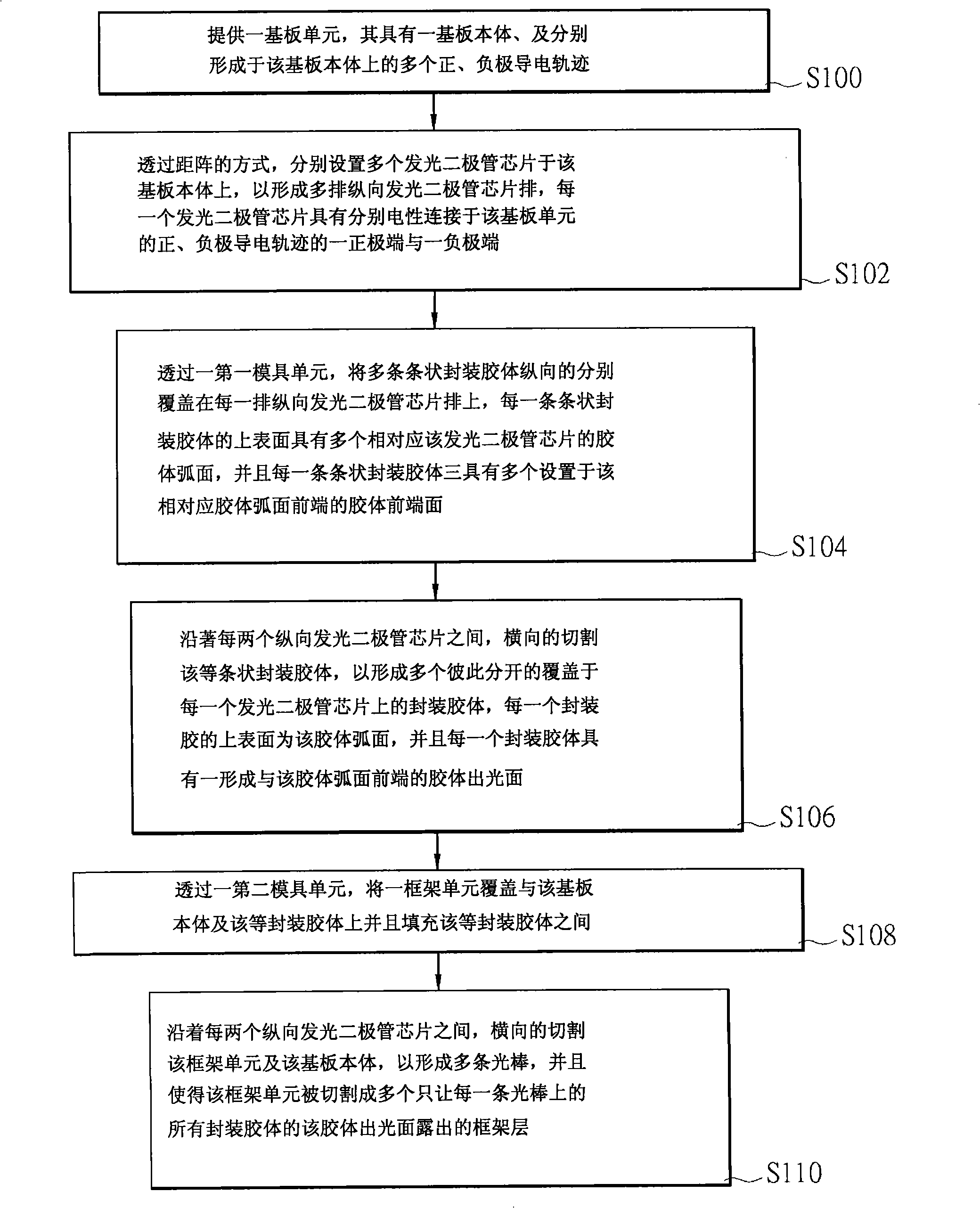

[0087] see Figure 4 , Figure 4 a to Figure 4 d, and Figure 1A to Figure 4 D shows. Figure 4 It is a flow chart of the first embodiment of the packaging method of the present invention, Figure 4 a to Figure 4 d are respectively the schematic diagrams of the packaging process of the first embodiment of the packaging structure of the present invention, Figure 4 A to Figure 4 D is a schematic cross-sectional view of the packaging process of the first embodiment of the packaging structure of the present invention, respectively. Depend on Figure 4 It can be seen from the flow chart that the first embodiment of the present invention provides a method for packaging a light-emitting diode with a high-efficiency lateral light-emitting effect, which includes the following steps:

[0088] First of all, please cooperate Figure 4 a and Figure 4 As shown in A, a substrate unit (substrate unit) 1 is provided, which has a substrate body (substrate body) 10, and a plurality of positiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com