Slushing oil painting apparatus for adjustable rails

A technology of anti-rust oil and guide rails, which is applied to devices and coatings that apply liquid to the surface, can solve problems such as damage to workers' health, affecting the smoothness of working surfaces, and frostbite on workers' hands, and achieve benefits for personal health, The effect of reducing production cost and labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

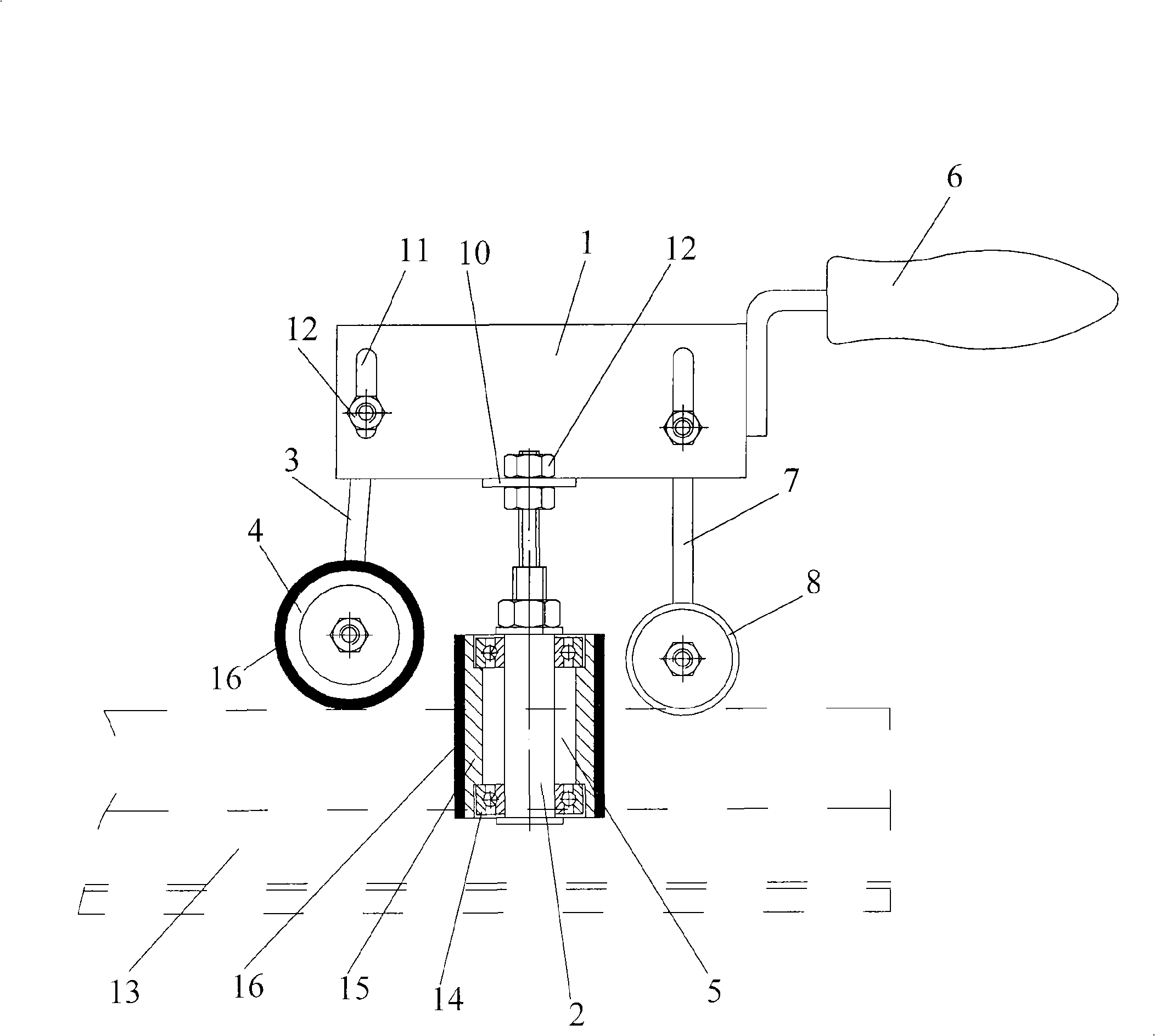

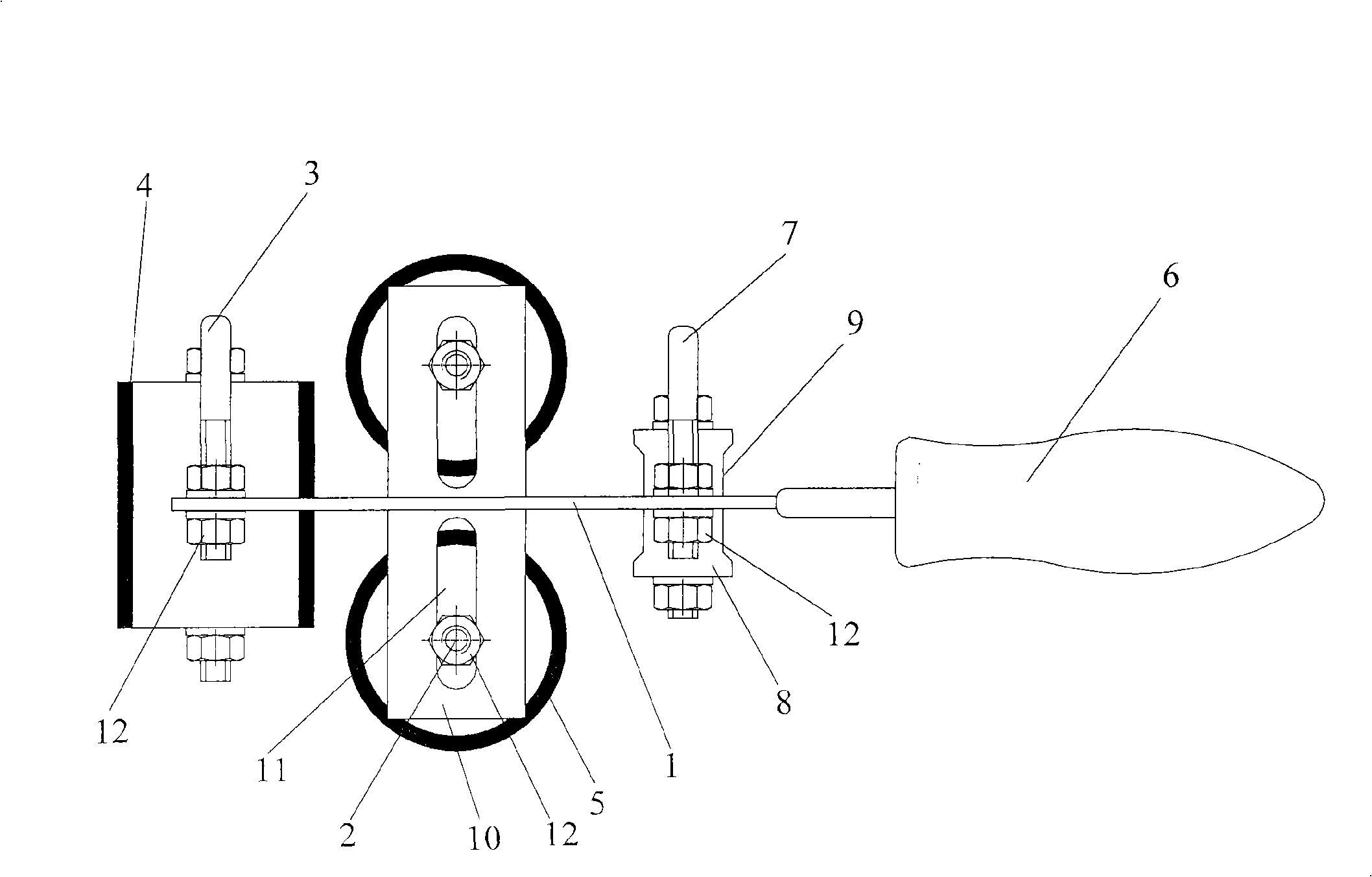

[0015] Example: such as figure 1 and figure 2 As shown, an adjustable guide rail antirust oil application device includes a device main body 1, a handle 6 fixed behind the device main body 1, a top roller connector 3 fixed to the device main body 1, and a pair of side roller connectors 2. The top roller connector 3 is equipped with a top oiling roller 4 that is in rolling contact with the top working surface of the guide rail 13, that is, the axis of the top oiling roller 4 is parallel to the top working surface of the T-shaped guide rail 13 and the outer surface of the top oiling roller 4 Roll on the top working surface; the pair of side roller connectors 2 are respectively equipped with side oiling rollers 5 that are in rolling contact with the two side working surfaces of the guide rail 13, that is, the axis of the side oiling roller 5 and the T-shaped guide rail 13 The side working surfaces of the side working surfaces are parallel and the outer surface of the side oilin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com