Label stripping apparatus

A peeling device and label technology, applied in the direction of labels, packaging, labeling machines, etc., can solve the problems of low efficiency, inconvenient manual peeling, tearing of self-adhesive labels, etc., and achieve the effect of simplifying the operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

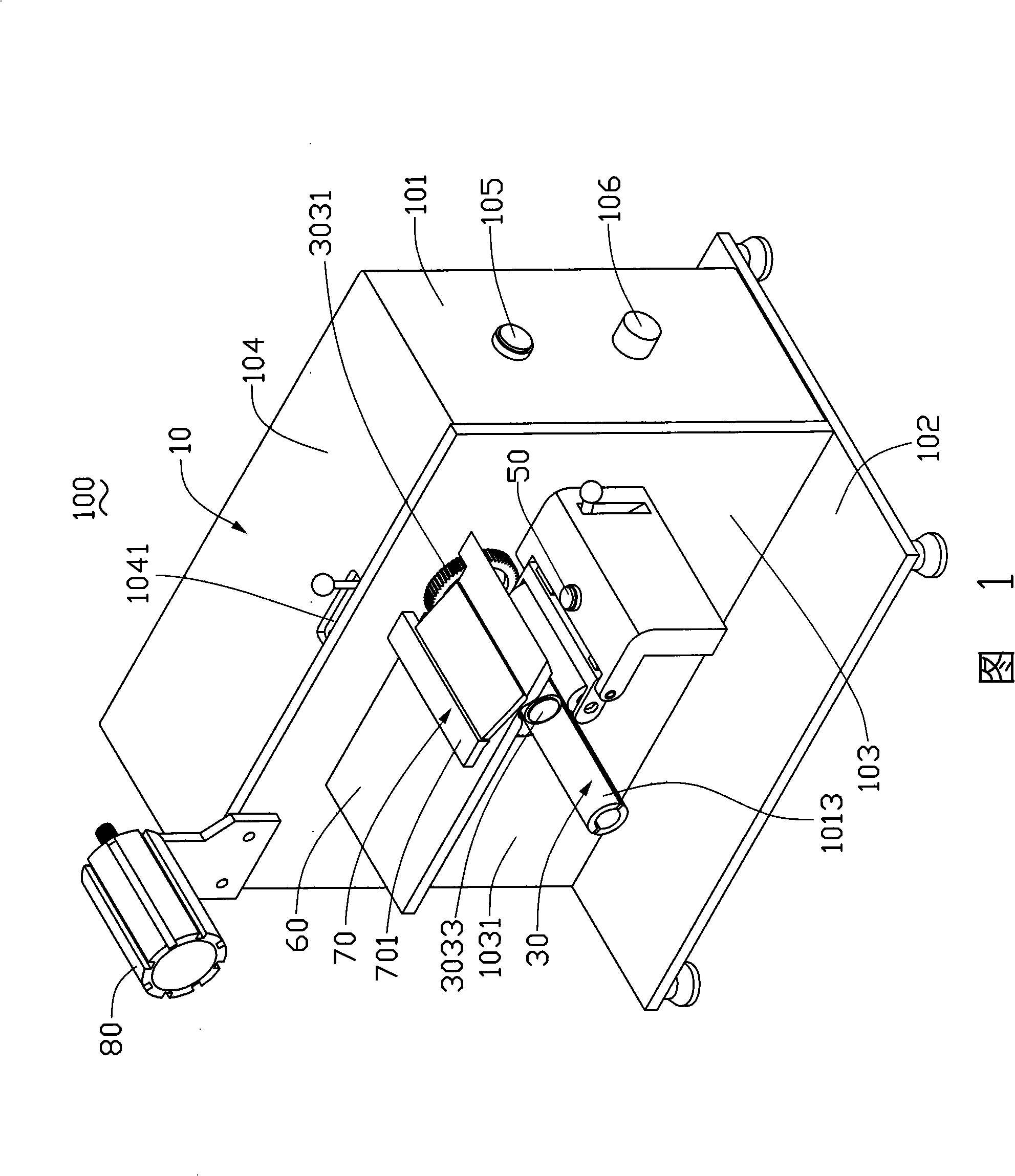

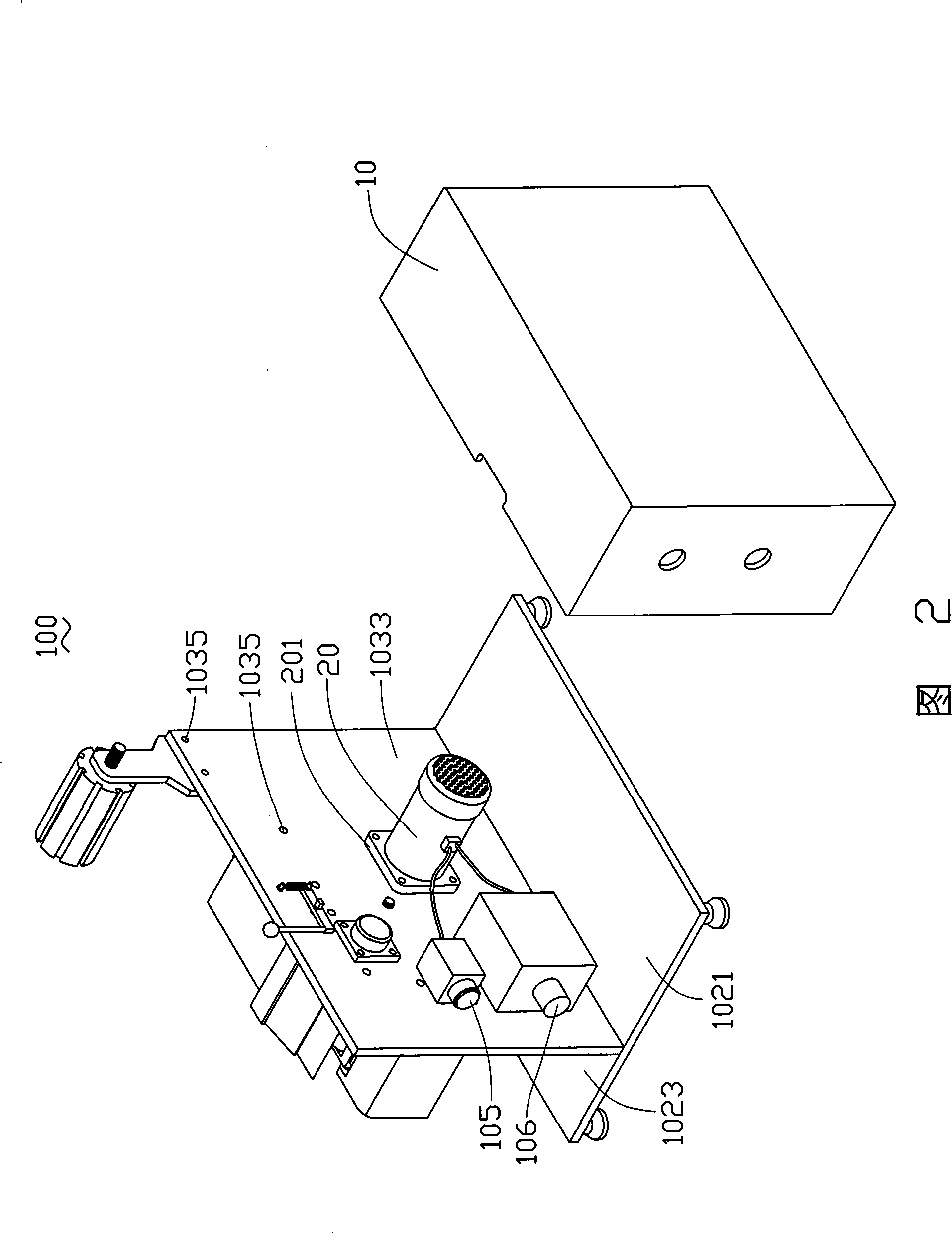

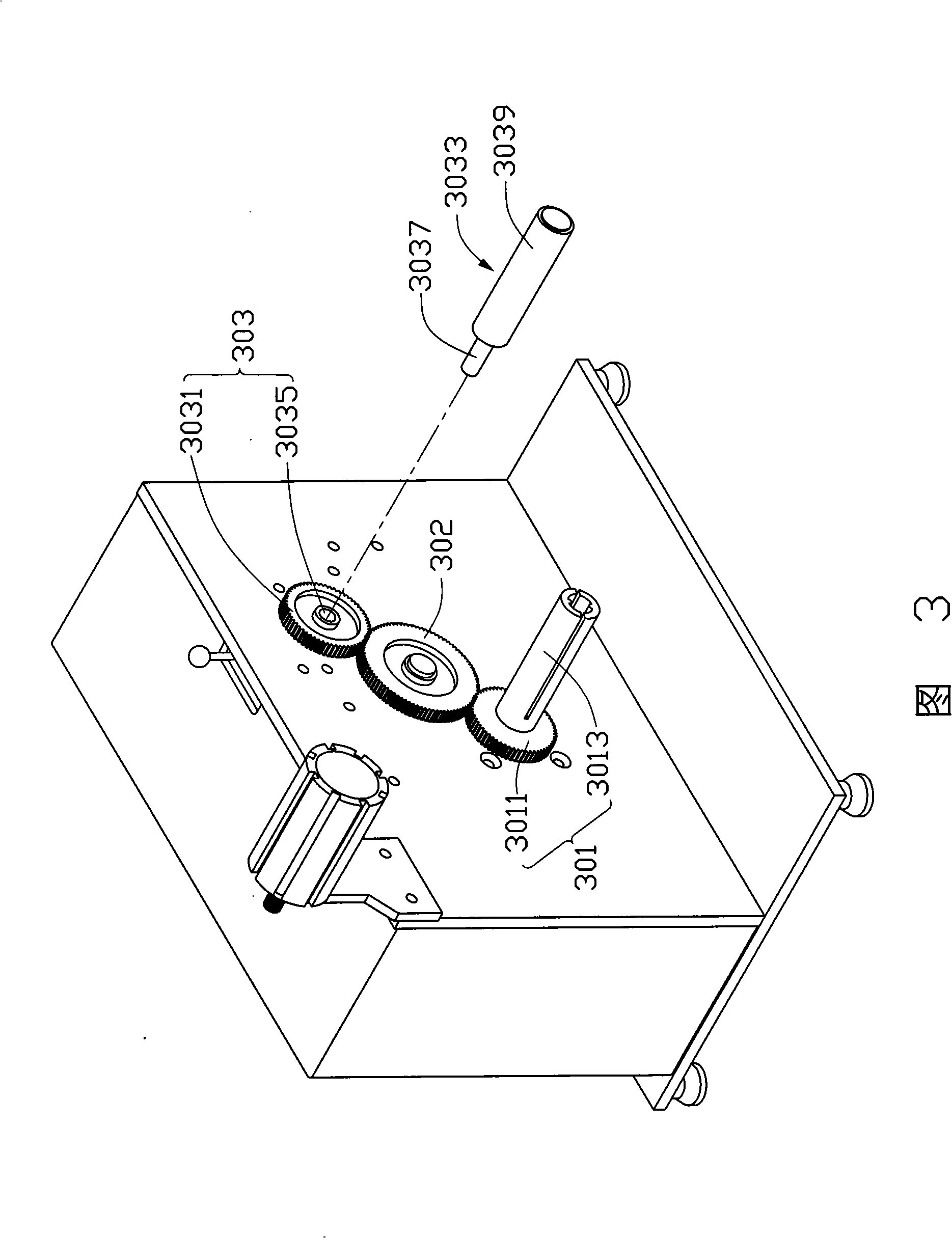

[0019] Please refer to a preferred embodiment of the label peeling device of the present invention shown in Figures 1 to 3, the label peeling device 100 can be used for peeling off the self-adhesive label of the roll-type release paper tape, and can also be used for the sheet-type release The stripping of the self-adhesive label of the paper tape includes a chassis 10, a power generating device 20 contained in the chassis 10, a release paper tape drag mechanism 30, a photoelectric switch 50, a peeling knife 60, a Pressing mechanism 70 and a transfer frame 80 . The power generating device 20 can be an electric motor or a cylinder, etc. In this preferred embodiment, an electric motor is used as an example for illustration. The photoelectric switch 50 is installed on the release paper tape driving mechanism 30 and is electrically connected with the power generating device 20 . The release tape dragging mechanism 30 , the stripping knife 60 , the pressing mechanism 70 and the tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com