Ink supplying ink box and core suction type writing instrument using the same

A writing tool and ink technology, applied in writing utensils, other ink pens, writing connectors, etc., can solve the problems of not being able to replace the suction core and not being easy to replenish ink, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

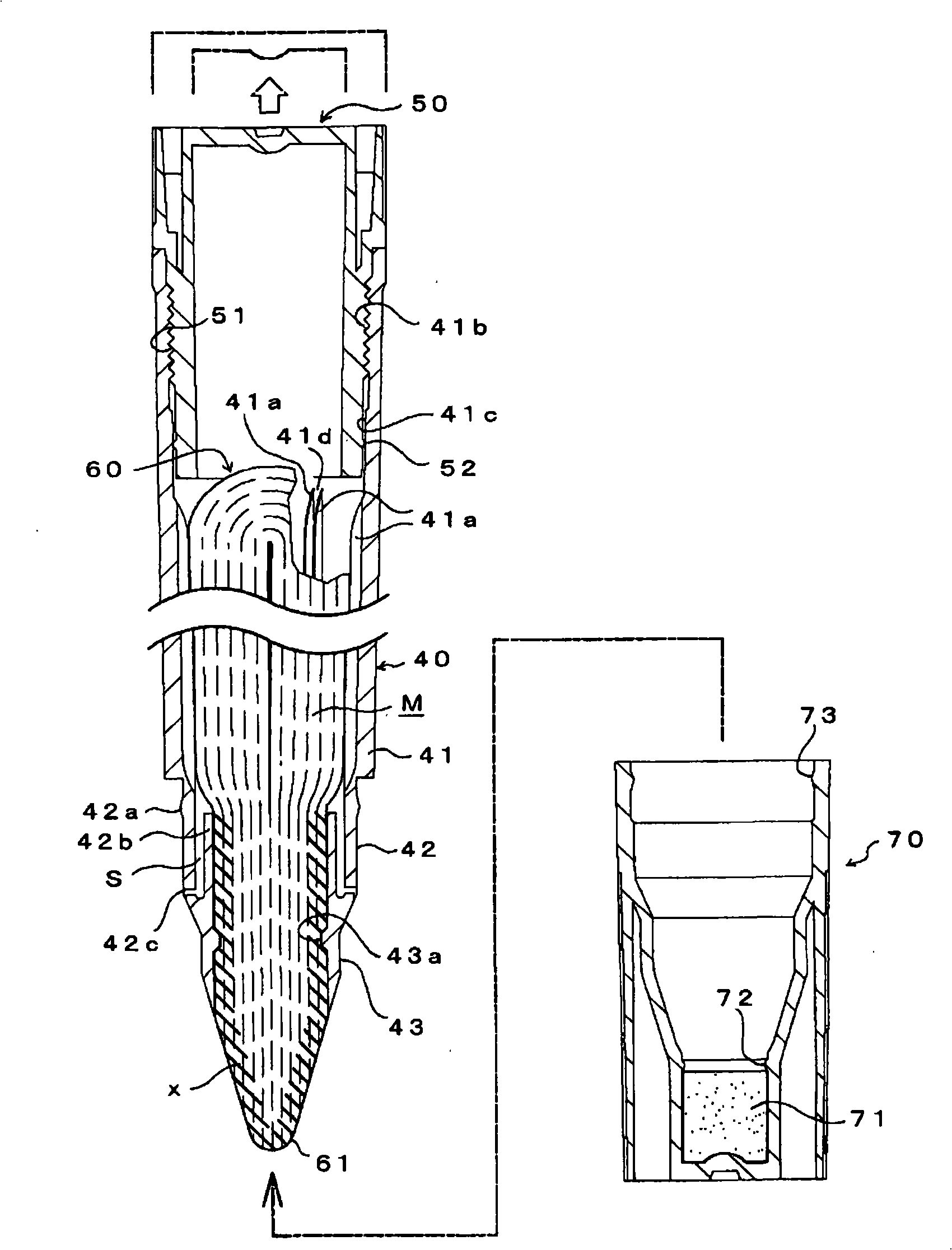

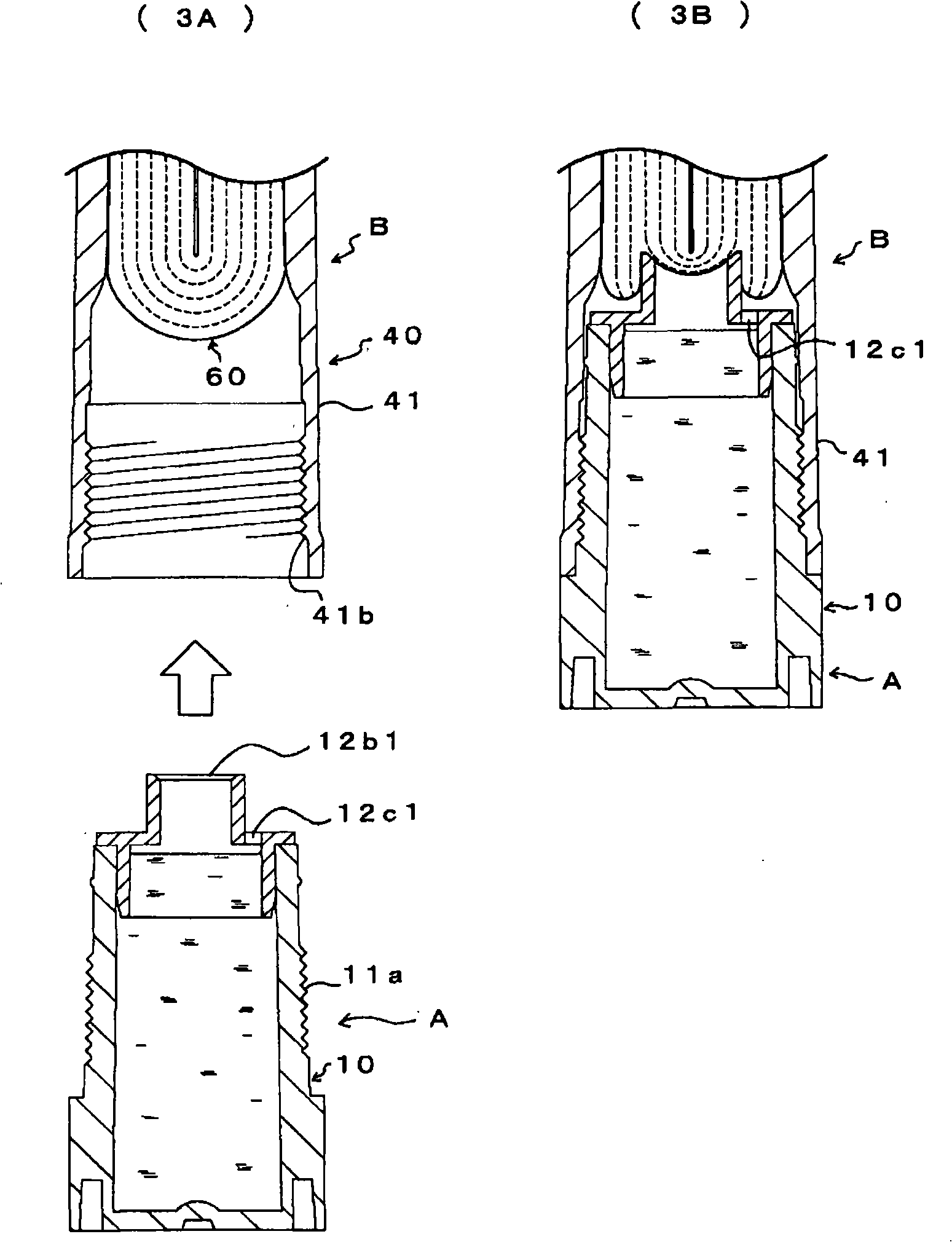

[0028] Embodiments of the present invention will be described below with reference to the drawings.

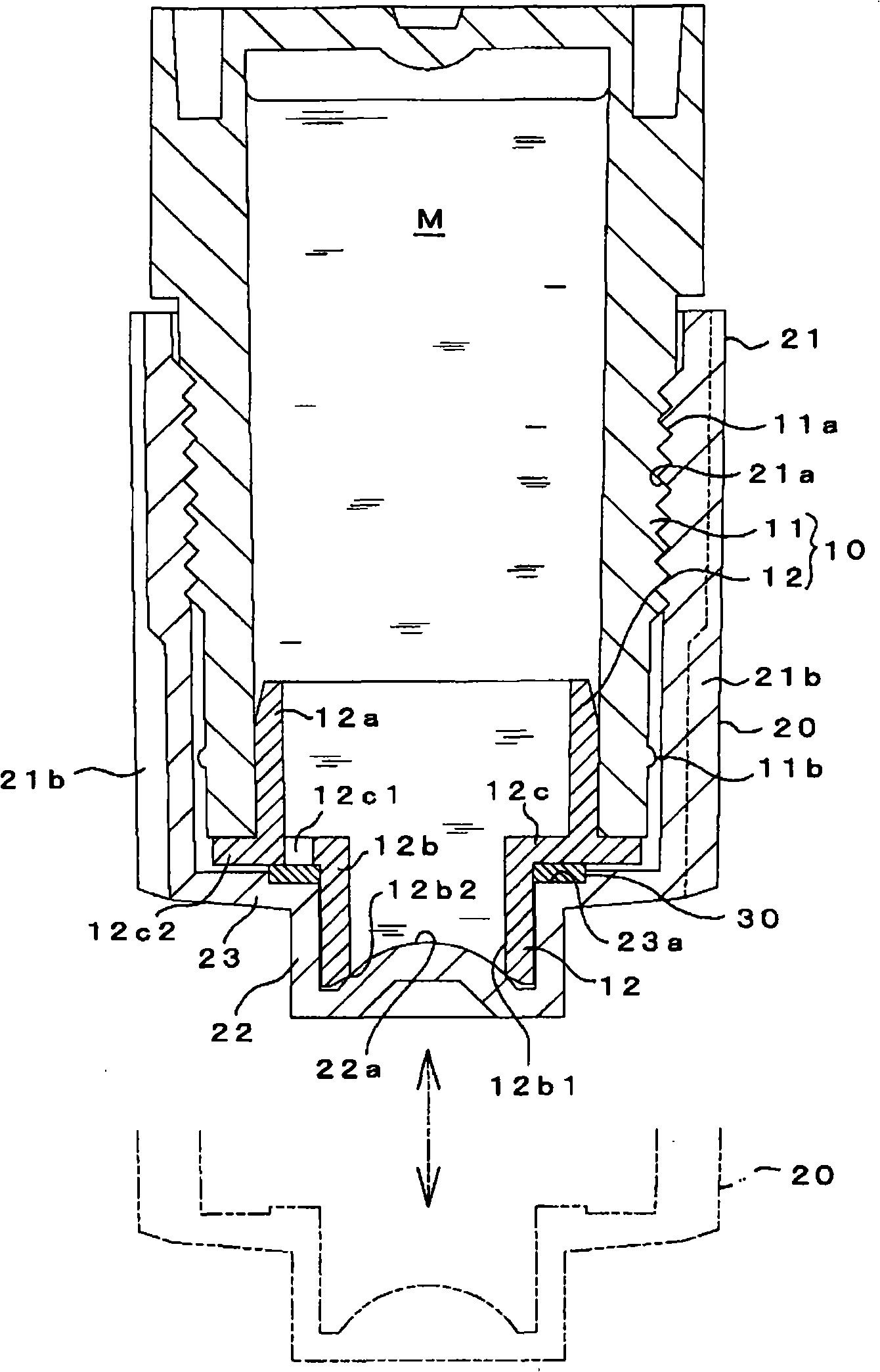

[0029] This ink replenishment ink cartridge A includes: an ink container 10 having an ink outlet 12b1; ink M filled in the ink container; the ink outlet 12b1 can be sealed to the ink container 10, and can be attached to and detached from the ink container. The attached seal cap 20 and the packing 30 interposed between the ink container 10 and the seal cap 20 are configured so as to be able to replenish ink M to a wicking writing instrument B described later.

[0030] The ink container 10 is integrally composed of a container main body 11 forming a space for storing ink M and an outlet member 12 forming an ink outlet 12b1.

[0031] The container main body 11 has a substantially bottomed cylindrical shape, and has an external thread portion 11a on its outer peripheral surface for screwing a sealing cap 20 described later. side ( figure 1 The lower end side in the middle) has a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com