Recycling and reusing method of slag-containing wastewater in stone processing process

A technology for stone processing and waste water, applied in the direction of candles, fatty acid production, candle components, etc., can solve the problem that there is no good treatment method for stone powder, and achieve the effect of improving leveling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

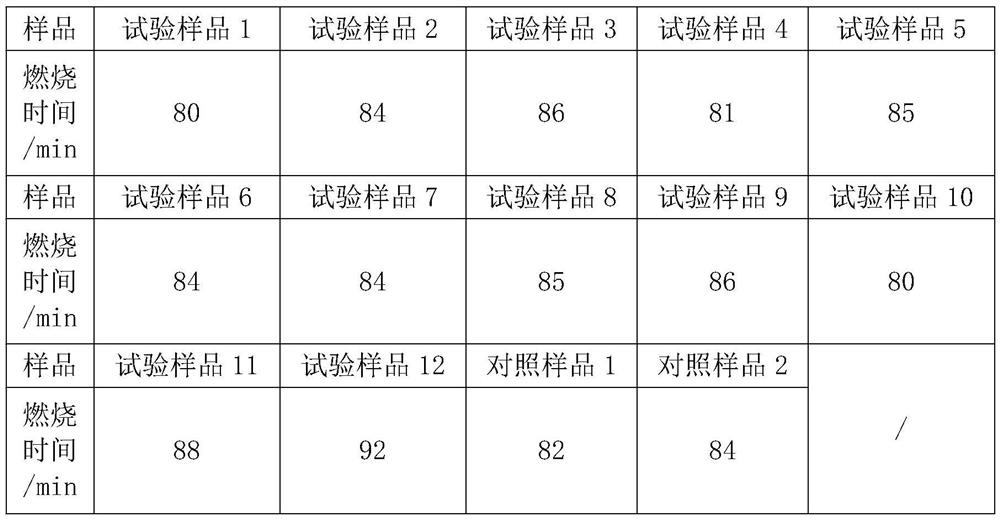

Examples

Embodiment 1

[0034] Embodiment 1: a method for recycling waste water containing slag in a stone processing process, comprising the following steps:

[0035] Step 1: After settling the water containing stone powder produced by stone processing, the water and the sediment at the bottom are preliminarily separated. In this embodiment, the sediment at the bottom is wet stone powder. Then the sediment at the bottom is passed into the tunnel furnace for baking to obtain semi-dry stone powder. In this embodiment, the moisture content of the semi-dry stone powder is 10%, and the mesh number of the semi-dry stone powder is between 32 and 400 mesh.

[0036] Step 2: put the semi-dry stone powder and molten paraffin into the blender according to the weight ratio of 1:3.5 and stir evenly, the stirring temperature is controlled at 65±5°C, and the stirring time is 5min to obtain the paraffin-stone powder mixture. In this embodiment, the raw material of the molten paraffin is No. 54 paraffin.

[0037] S...

Embodiment 2

[0038] Embodiment 2: A method for recycling slag-containing waste water in a stone processing process. The difference from Example 1 is that the moisture content of the semi-dry stone powder obtained in step 1 is 13%; The weight ratio of paraffin wax is 1:4.

Embodiment 3

[0039] Embodiment 3: A method for recycling slag-containing waste water in a stone processing process. The difference from Example 1 is that the moisture content of the semi-dry stone powder obtained in step 1 is 15%; The weight ratio of paraffin wax is 1:5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com