Oil-water automatic segregator

An automatic separator, oil-water technology, applied in the direction of liquid separation, separation methods, chemical instruments and methods, etc., can solve the problems of different purity, oil-water separator can not meet the requirements, etc., to achieve the effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

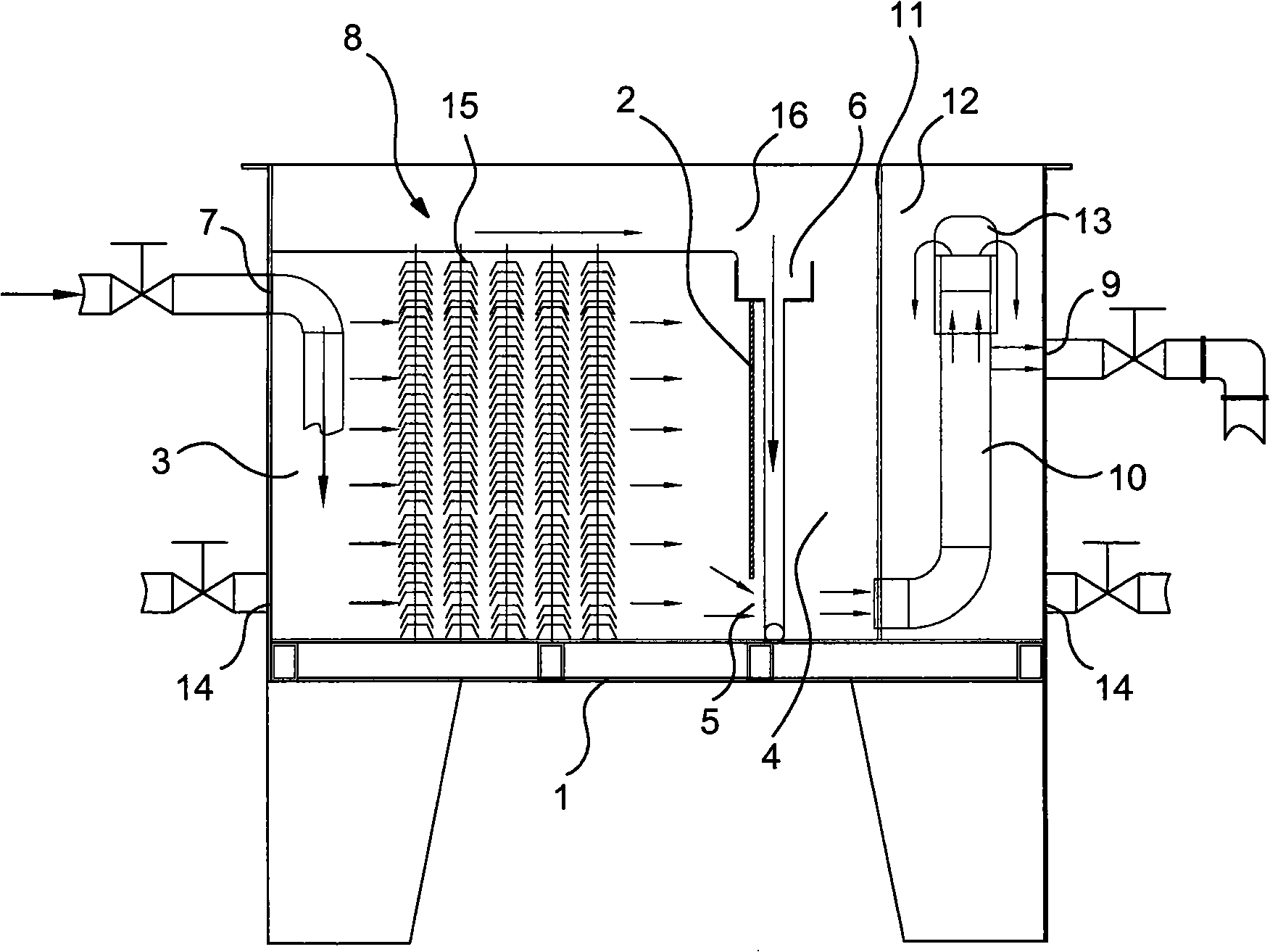

[0011] Such as figure 1 The shown oil-water automatic separator includes an open water tank 1, a partition 2 arranged in the water tank 1 and arranged along the vertical direction, the water tank 1 has an oil-water mixture inlet 7 on its left side, and a water-water mixture inlet 7 on the right side. The water outlet 9 and the partition 2 divide the inner cavity of the water tank 1 into a left chamber 3 and a right chamber 4. The upper part of the left chamber 3 communicates with the oil sump 6 through a gap 16, and the lower part of the left chamber 3 passes through the 2. The water return port 5 at the lower bottom communicates with the right chamber 4. An oil-water filter device 8 is arranged in the left chamber 3. As shown in the figure, the oil-water filter device 8 is composed of several orifice plates 15 stacked together. Usually these orifice plates are made of grooved bent plates with a thickness of 1.5mm, and these grooved bent plates are connected in series. When t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com