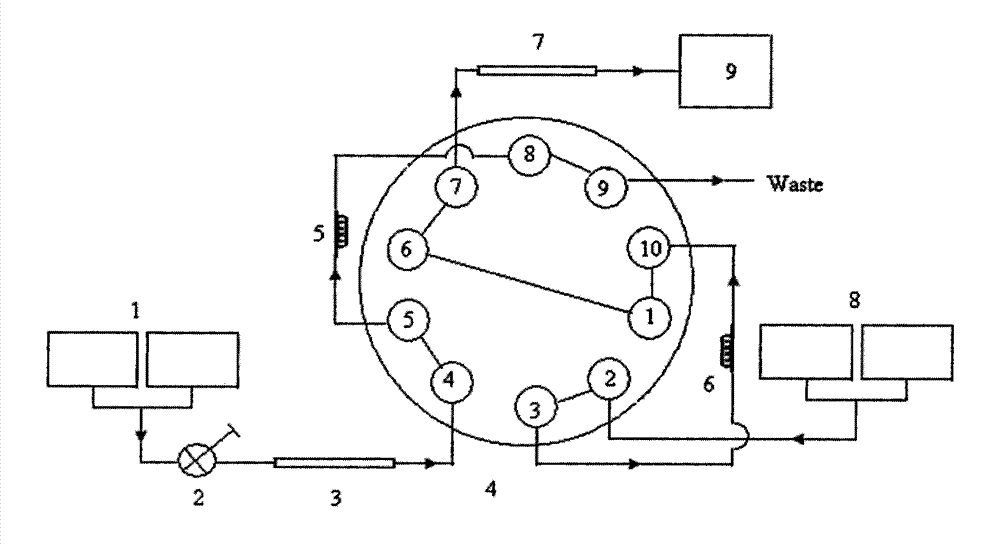

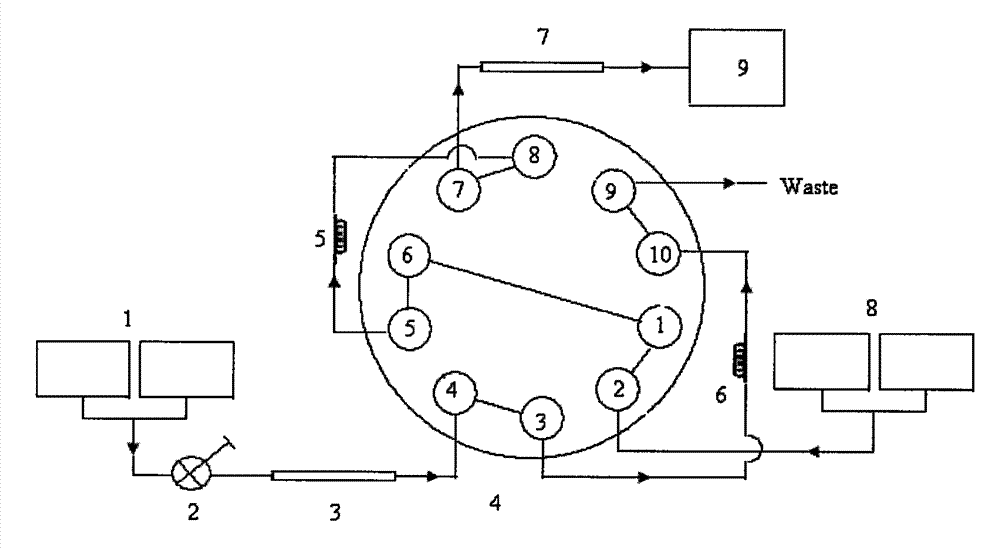

Comprehensive two-dimensional ultrahigh pressure high performance liquid chromatography separation system

A high-pressure liquid chromatography and high-performance liquid chromatography technology, which is applied in the field of high-performance liquid chromatography separation systems, can solve problems such as dilution, reduce sample detection sensitivity, and speed up the second-dimensional separation time to achieve fast and efficient separation, fast and effective separation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

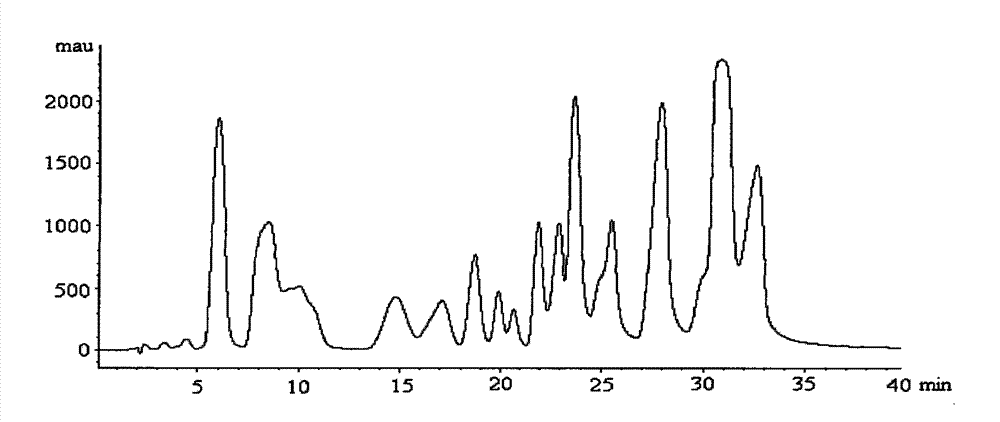

[0022]Prepare a mixed solution of standard samples containing 37 components, 1.1,3-difluorobenzene (1,3-difluorobenzene), 2.nonanophenone (nonaphenone), 3.nitrobenzene (nitrobenzene), 4.benzyl butylphthalate (Benzyl butyl phthalate), 5.2,4-dinitrochlorobenzene (1-chloro-2,4-dinitrobenzene), 6.thioanisole (anisole sulfide), 7.bromobenzene (bromobenzene), 8 .acetophenone (acetophenone), 9.1, 4-bis(trifluoromethyl)benzene (1,4-bis(trifluoromethyl)benzene), 10.octanophenone (phenyloctyl ketone), 11.1,3-bis(trifluoromethyl)benzene (1,3-bis(trifluoromethyl)benzene), 12.anisole (anisole), 13.butylbenzene (n-butylbenzene), 14.ethylbenzene (ethylbenzene), 15.hexanophenone (n-hexylbenzene) , 16.heptanophenone (n-heptylbenzene), 17.fluorobenzene (fluorobenzene), 18.a, a, a, -trifluorotoluene (a, a, a- trifluorotoluene), 19.diethyl phthalate (phthalic acid Diethyl ester), 20.triptycene (triptycene), 21.indolebenzene (iodobenzene), 22.benzene (benzene), 23.pentylbenzene (amylbenzene) (ben...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com