A new filter separator

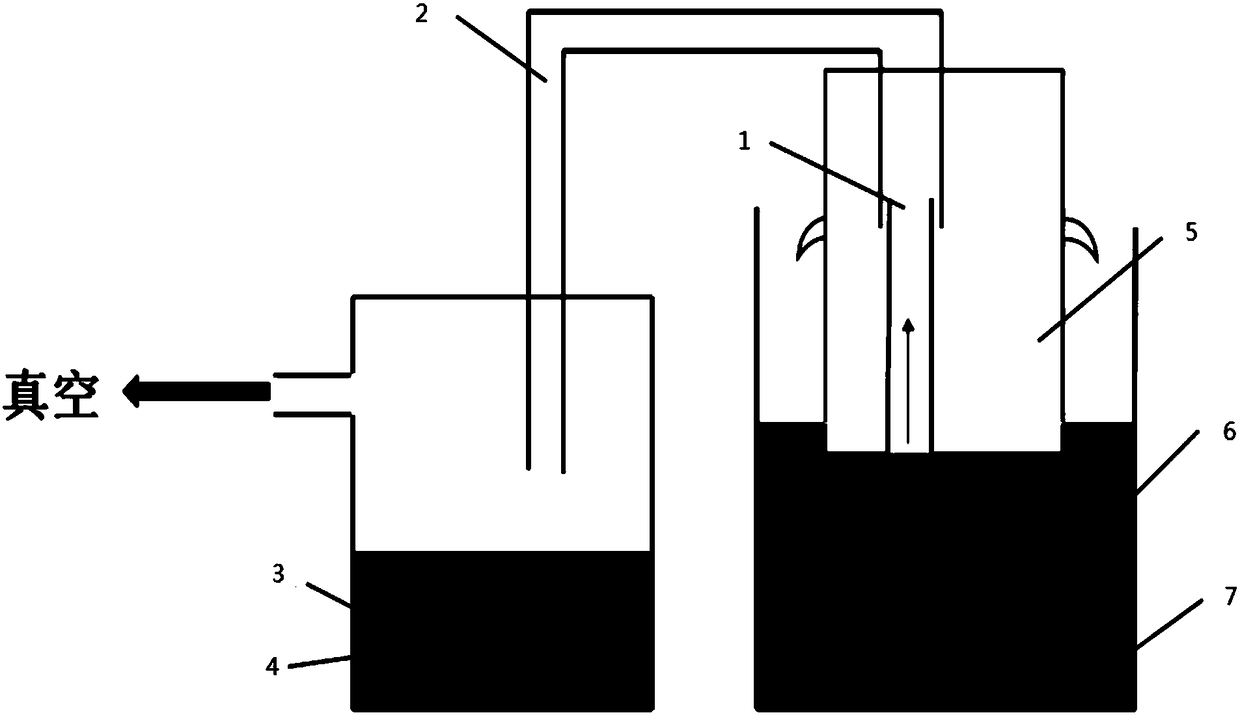

A filter separator and filter separation technology, which is applied in the direction of filter separation, membrane filter, gravity filter, etc., to achieve the effect of saving time and reducing the loss of solid matter in the operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

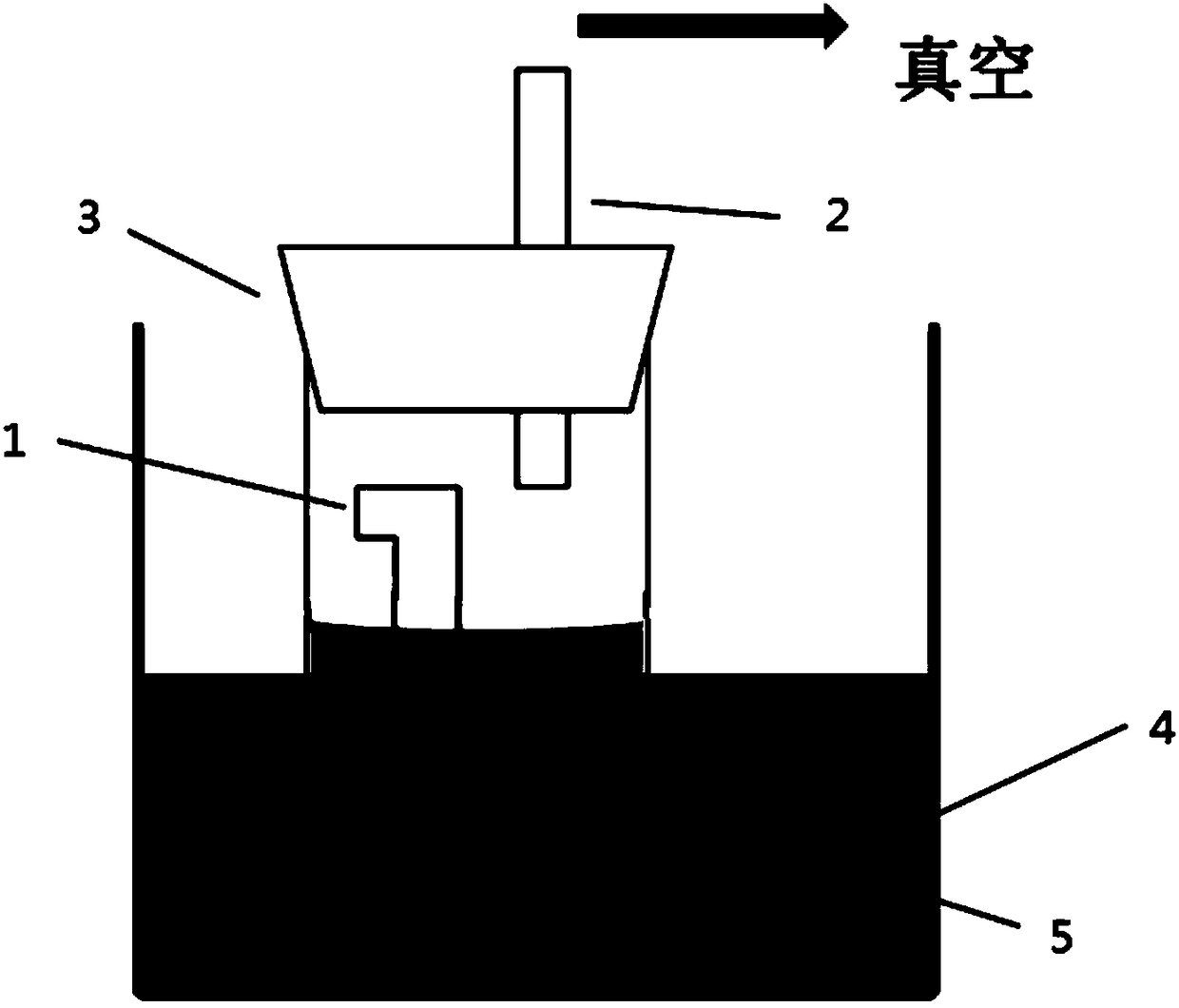

[0054] Embodiment 1: filter the method for calcium carbonate and copper sulfate mixture with filter separator of the present invention.

[0057] 100g deionized water

[0058] The solid-liquid mixture formed above, because the upper layer contains a small amount of solid particles, the liquid presents an opalescent phenomenon. Put the novel filter of the present invention into it, connect the upper end to the vacuum pump, and turn on the vacuum pump, and the blue filtrate flows out smoothly from the elbow. When finished, unplug the hose from the vacuum pump, turn off the vacuum pump, and take out the filter. The filtrate can be easily poured out of the filter to achieve solid-liquid separation.

[0059] The above-mentioned experimental results show that the novel filter of this invention has inherited the advantages of the inverted siphon filter invented in our previous work. During most of the filtration process, t...

Embodiment 2

[0060] Embodiment 2: the method for suction filtering 80% polyethylene glycol aqueous solution with filter separator of the present invention.

[0061] Polyethylene Glycol 80%

[0062] Deionized water 20%

[0063] After polyethylene glycol is melted into a solution, water is added to make an 80% aqueous solution of polyethylene glycol. It is solid at room temperature and cannot be filtered. When the solution is placed in a constant temperature water bath at about 45 degrees, the crystallization situation is most suitable for suction filtration. The novel filter of the present invention is put into it, and the upper end is connected to a vacuum pump, and the liquid to be filtered is kept at a constant temperature in a water bath to avoid solidification during the suction filtration process. Submerge the liquid through the bottom of the filter and turn on the vacuum pump. Viscous liquid flows out of the nozzle. When the filtrate is close to the lower end of the nozzle, stop...

Embodiment 3

[0064] Embodiment 3: filter the method for potassium nitrate with filter separator of the present invention

[0065] Use 300 grams of deionized water at about 65 degrees, add about 200 grams of potassium nitrate, stir until it is basically dissolved, then add about 100 grams of calcium carbonate to form a mixed solution of calcium carbonate and potassium nitrate, and use the filter of the present invention to filter Out of potassium nitrate solution:

[0066] Put the prepared liquid to be filtered into a constant temperature water tank with a constant temperature of 65 degrees, put a new filter into it, and connect the upper end to a vacuum pump. After turning on the vacuum pump, the filtrate flows out from the nozzle smoothly, and the suction filtration process is about 10 seconds. After the suction filtration is finished, turn off the vacuum pump and take out the new filter. At this point no crystals had formed in the filter, and the liquid was poured into a beaker and all...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com