Three-arm type noncooperative target docking mechanism

A non-cooperative target and docking mechanism technology, which is applied in the field of satellite docking mechanism, can solve the problems of extremely high motion precision and low docking success rate, and achieve low motion precision requirements, improved reliability, and high success rate.

Active Publication Date: 2010-11-10

HARBIN INST OF TECH

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to provide a three-arm non-cooperative target docking mechanism to solve the problem that the existing satellite docking mechanism has a relatively low docking success rate and requires extremely high motion accuracy

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment approach 1

specific Embodiment approach 2

specific Embodiment approach 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

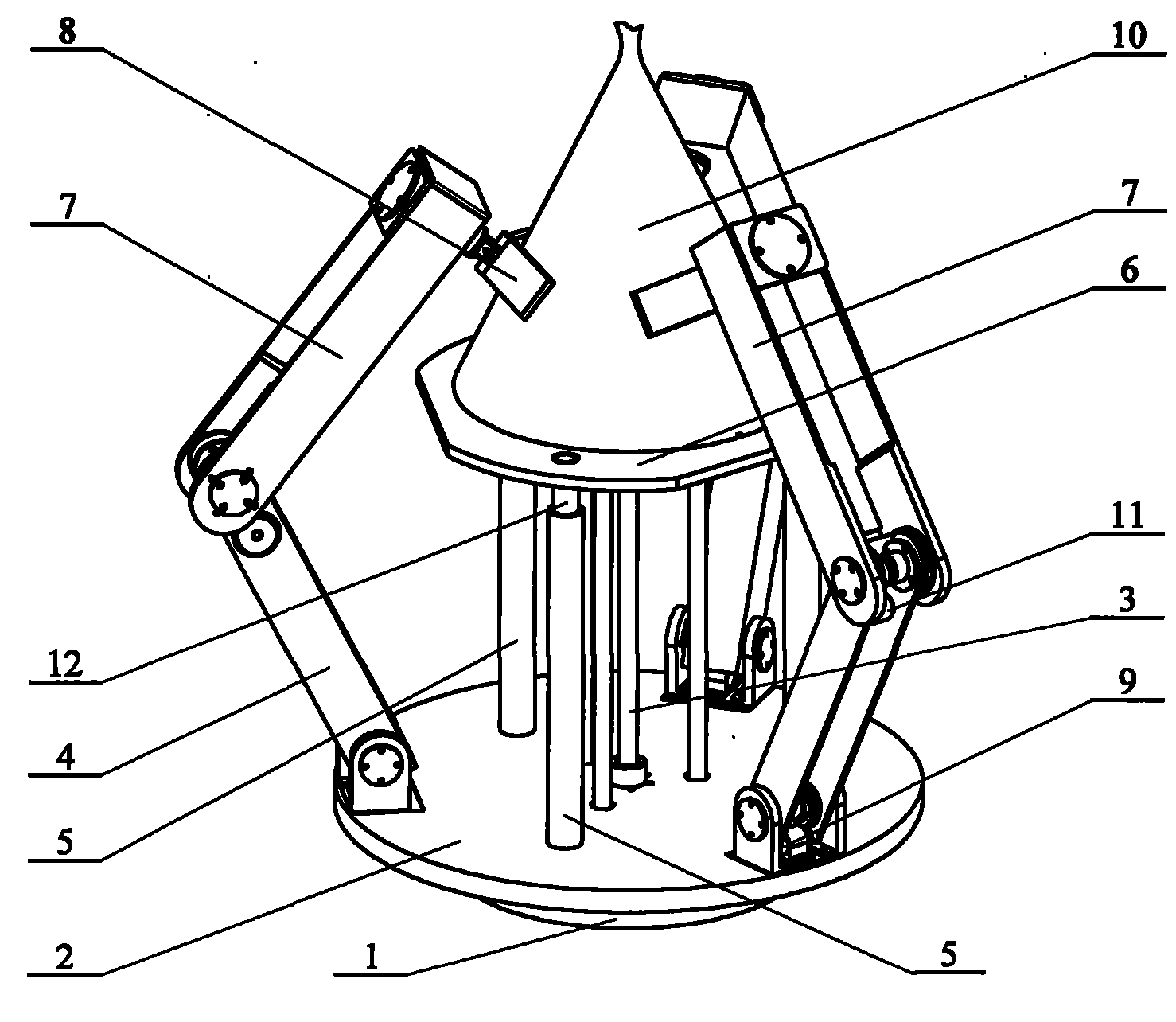

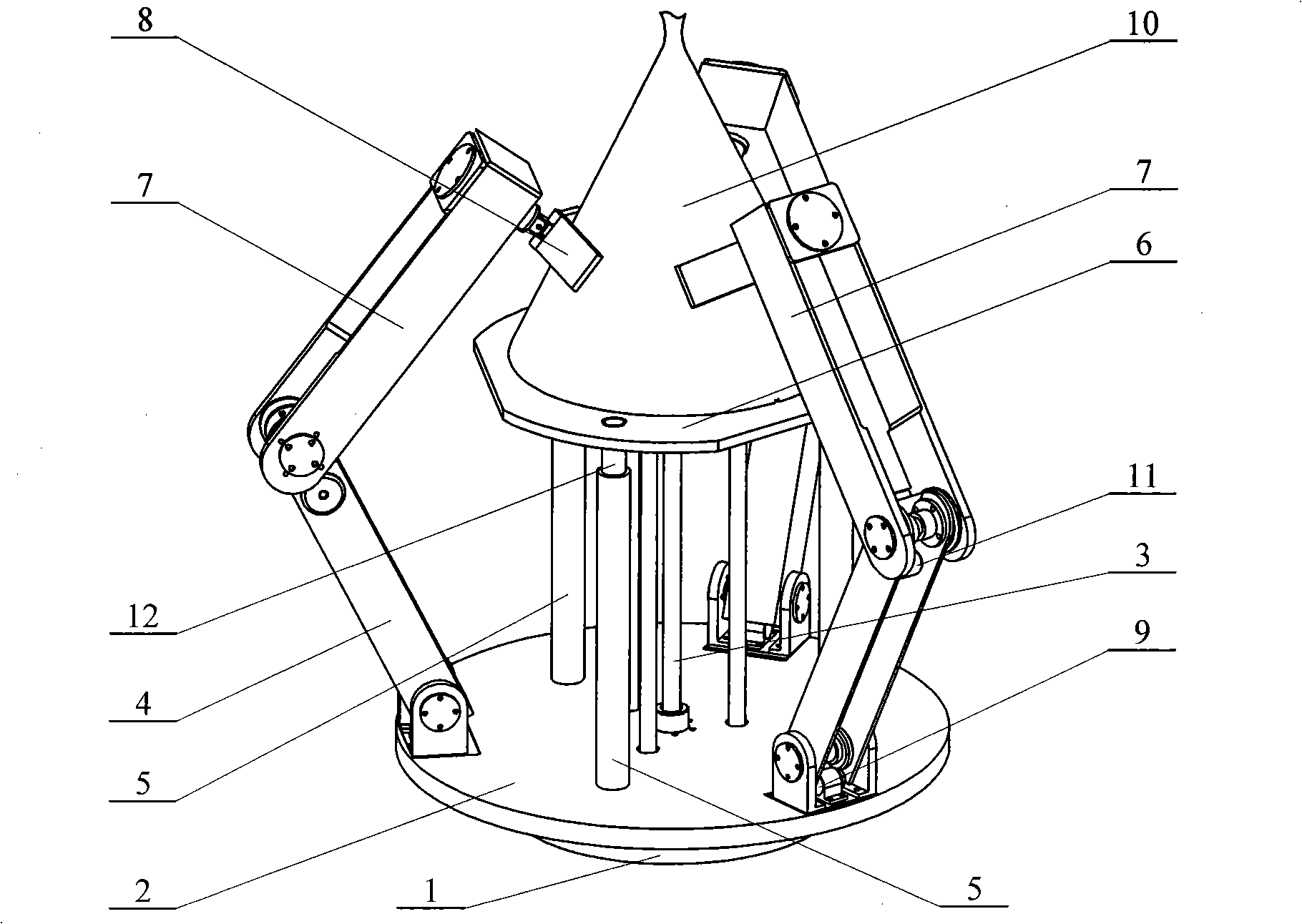

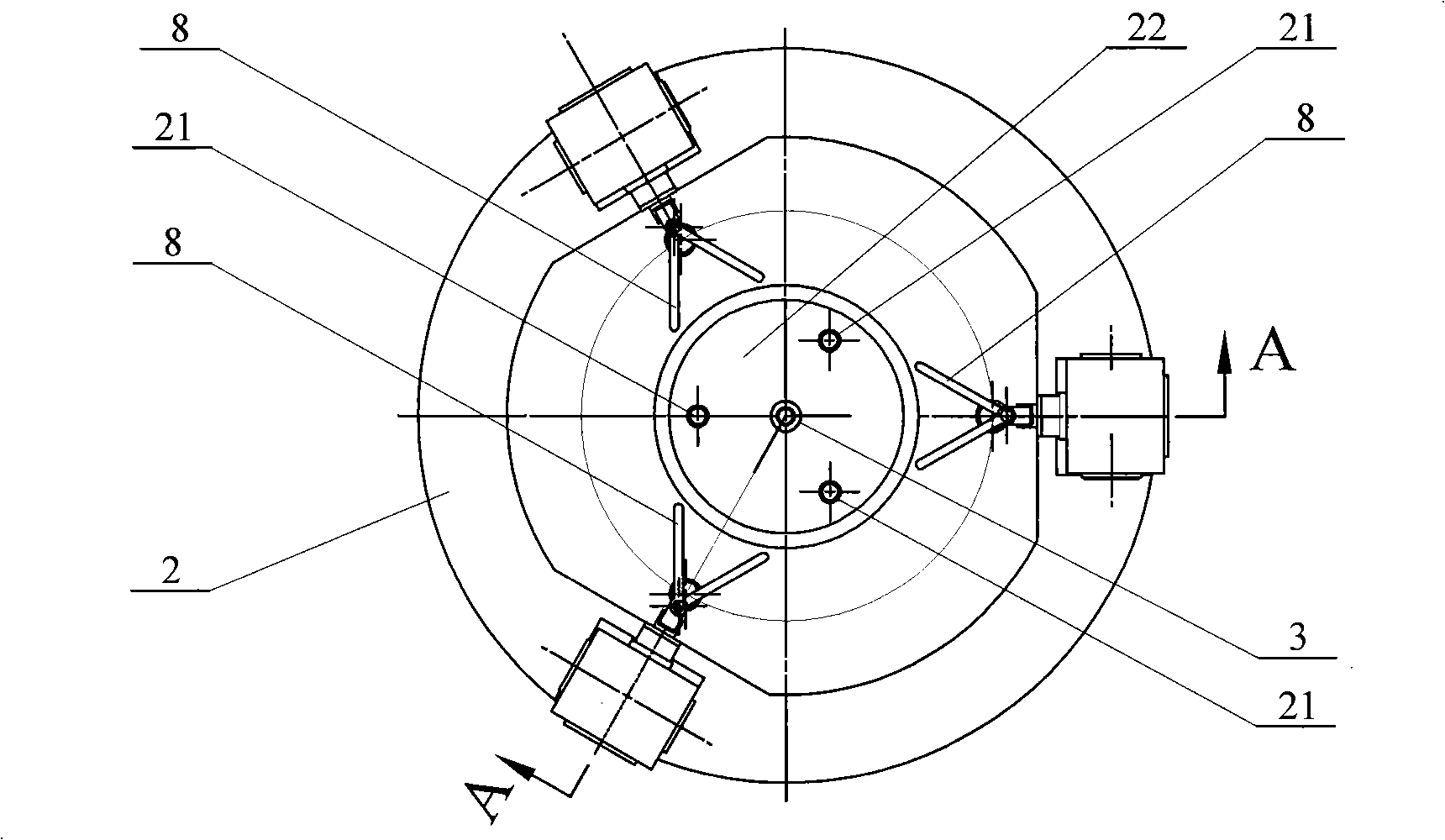

The invention discloses a three-arm type non-cooperative target docking mechanism, relating to a satellite docking mechanism. The invention aims at solving the problems that the docking success rate of the existing satellite docking mechanism is comparatively low and the requirement on motion precision is extremely high. The three large mechanical arms of the invention are arranged on the periphery of a supporting platform at a 120 degree angle, one end of the large arm of the mechanical arm is articulated with the supporting platform, the other end thereof is articulated with one end of the small arm of the mechanical arm, and the other end of the small arm of the mechanical arm is connected with an end effector; the lower end of each bumper post is fixedly connected with the upper end of the supporting platform, the free end of each dashpot plunger is fixedly connected with the lower end of a target docking platform. In the invention, when the docking mechanism reaches a preset position, the three mechanical arms and the target docking platform form a closed region to encase a jet pipe, therefore, the jet pipe is placed in an inescapable space, and a target aircraft is clamped and fixed by the underdraught of the three mechanical arms and the upthrust of the target docking platform.

Description

Three-arm non-cooperative target docking mechanism technical field The invention relates to a satellite docking mechanism. Background technique The non-cooperative target docking technology is different from the previous docking technology, and its docking target is a satellite without a docking interface. Therefore, the apogee recoil engine (AKM) nozzle of the satellite is generally selected as the docking interface. The existing non-cooperative target docking mechanism is shown in FIG. 7 , including a tension pin 16 , a docking rod 17 , a motor 18 , a sensor 19 , and a docking mechanism housing 20 . The working principle of the docking mechanism is: the tension pin 16 installed on the docking rod 17 is driven by the motor 18 to move closer to the throat of the AKM nozzle, and when the sensor 19 detects that it is inserted into the throat of the AKM nozzle, the sensor 19 sends out a signal , drive the tensioning pin 16 to expand, thereby docking with the target. But th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B25J1/02B64G1/64

Inventor 张广玉李隆球柏合民范佐董惠娟王晓雪

Owner HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com