Sound deadening shock absorption rail joints of coak joint staggered joints

A technology for damping rails and rail joints, which is applied to rail joints, rails, roads, etc., and can solve problems such as vibration and noise, loss of passenger comfort, and impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] specific implementation plan

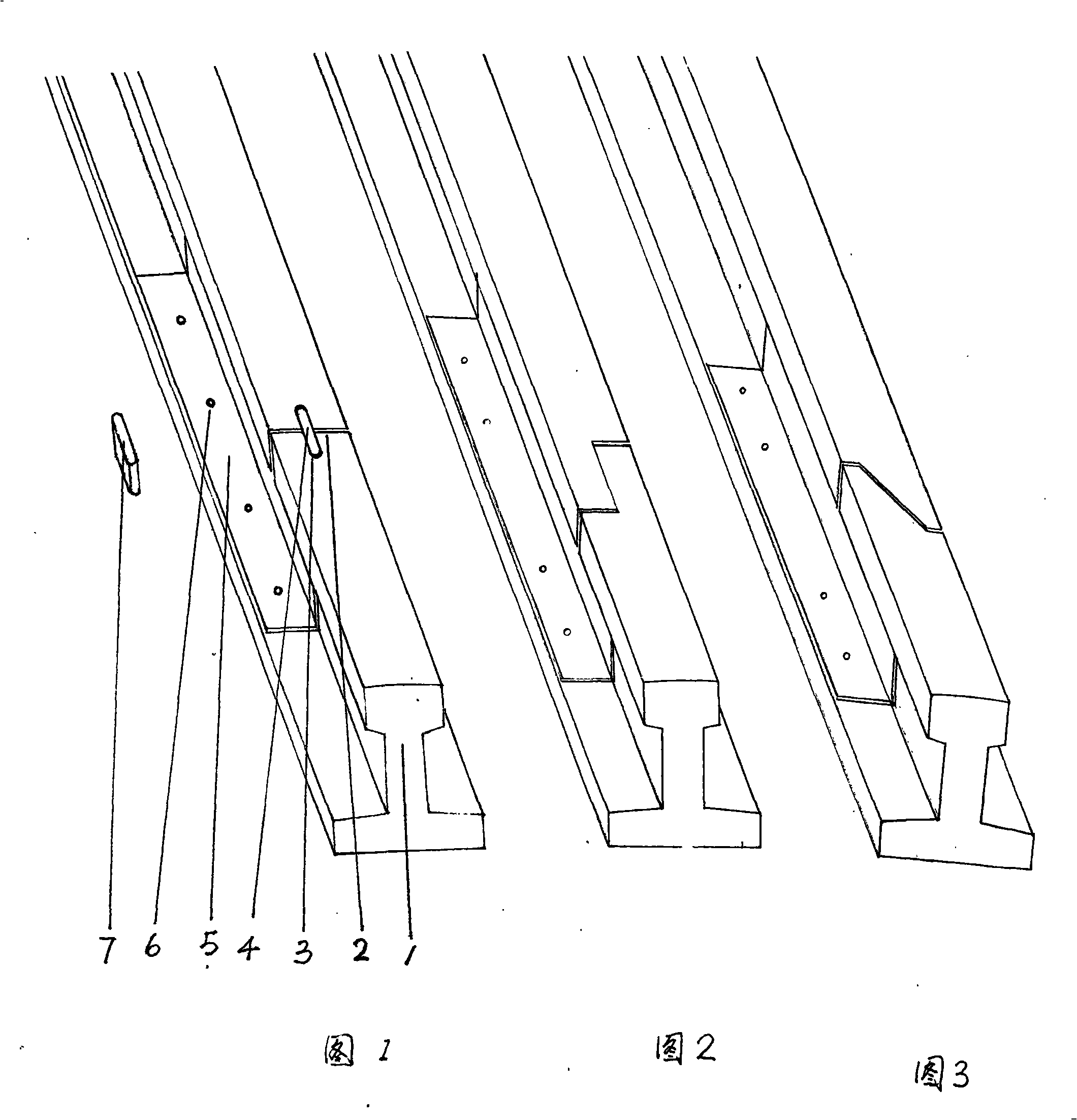

[0015] As shown in Fig. 1, the noise-absorbing and shock-absorbing track joint of the buckle-tenon connection of the present invention, the two joints 2 of the track 1 are excavated, drilled and milled to 15 mm at each end, and the two ends are 30 mm in total, 10 mm wide, and 30 mm deep. The female groove tenon 3 is fitted with the connecting male tenon 4 whose shape and specification match the female groove tenon to complete the buckle tenon connection and staggered seams, and it is clamped by the joint steel plate clamp 5, and the screw 6 is tightened to connect and fix it as an embodiment. .

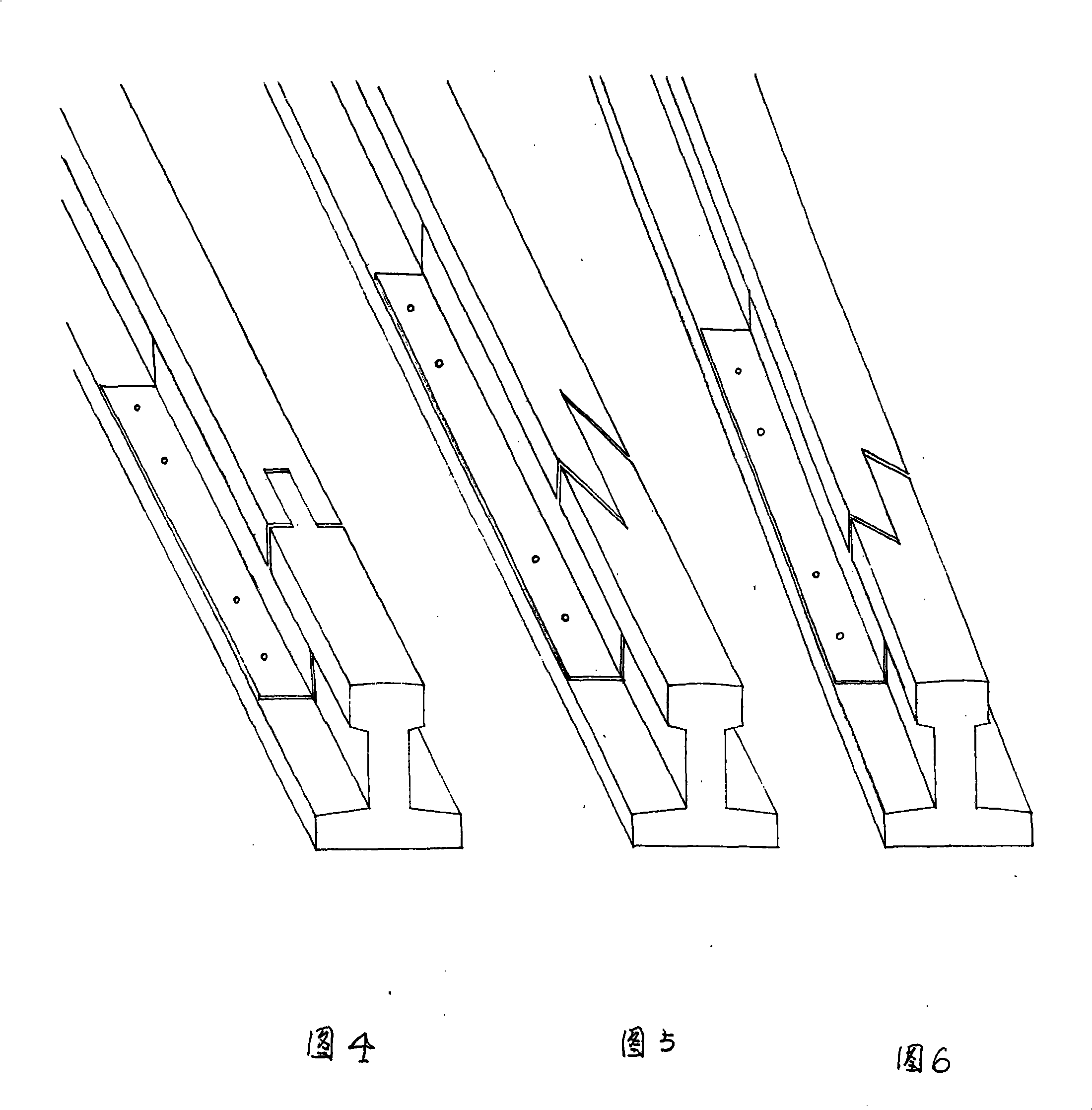

[0016] Fig. 2 is the present invention An embodiment of a noise-absorbing and shock-absorbing track joint with tenons and tenons in the middle, long and short, and tenons lapped and alternately staggered.

[0017] Fig. 3 is the present invention An embodiment of a noise-absorbing and shock-absorbing track joint with tenons on both sides cut i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com