Aluminum profile connector and vehicle body framework

A technology of aluminum profile and interface, which is applied in the connection between vehicle components, superstructure sub-assemblies, superstructure, etc. It can solve the problems of poor stability of the body frame, large welding deformation of profiles, and short service life, etc., to achieve the connection form Flexible and diverse, low processing cost, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention. In addition, it should be noted that, for the convenience of description, only the parts related to the present invention are shown in the drawings but not all of them.

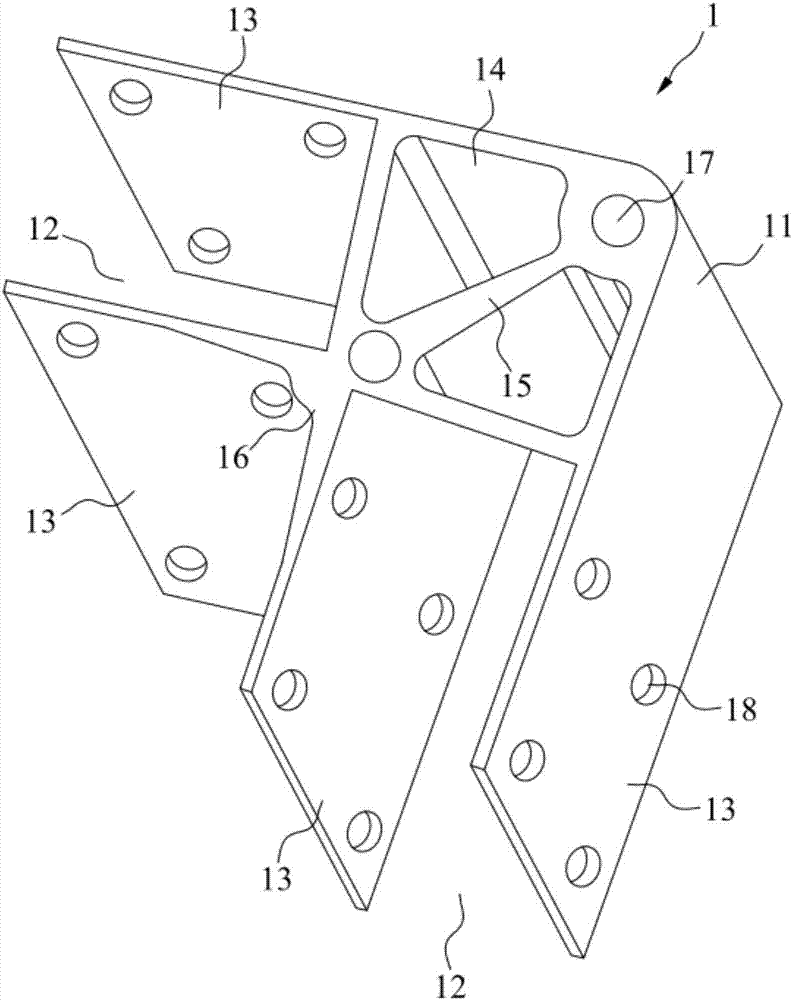

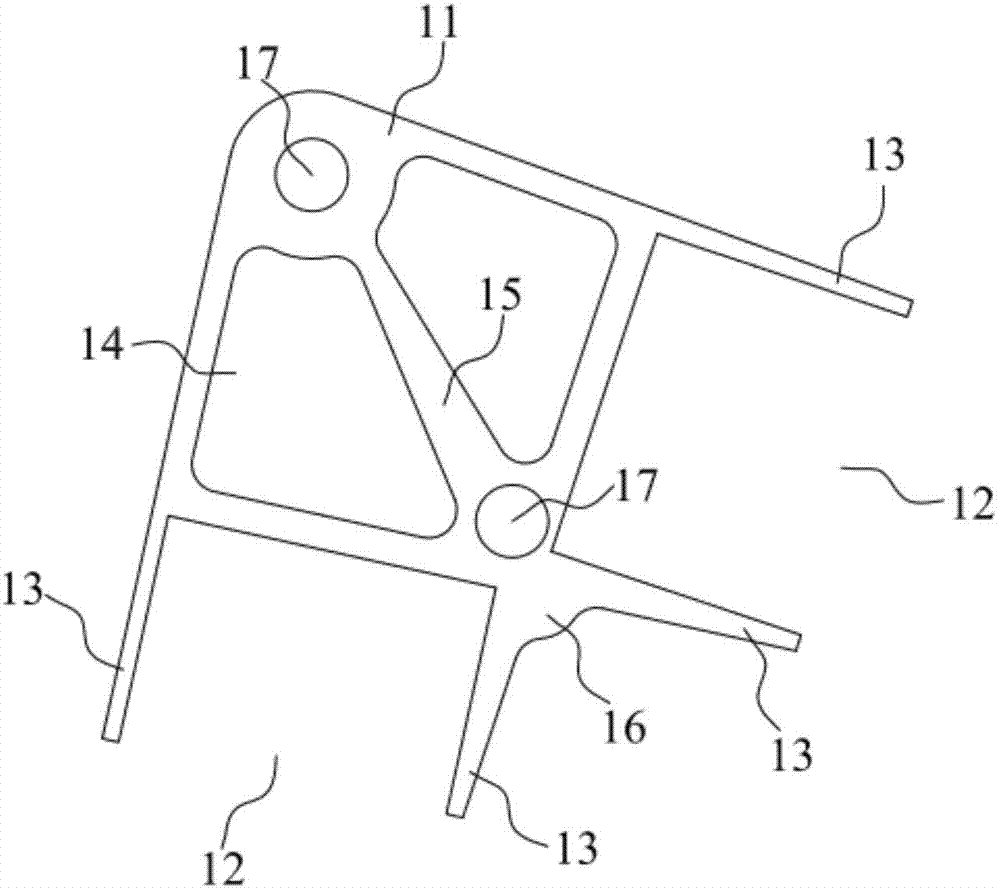

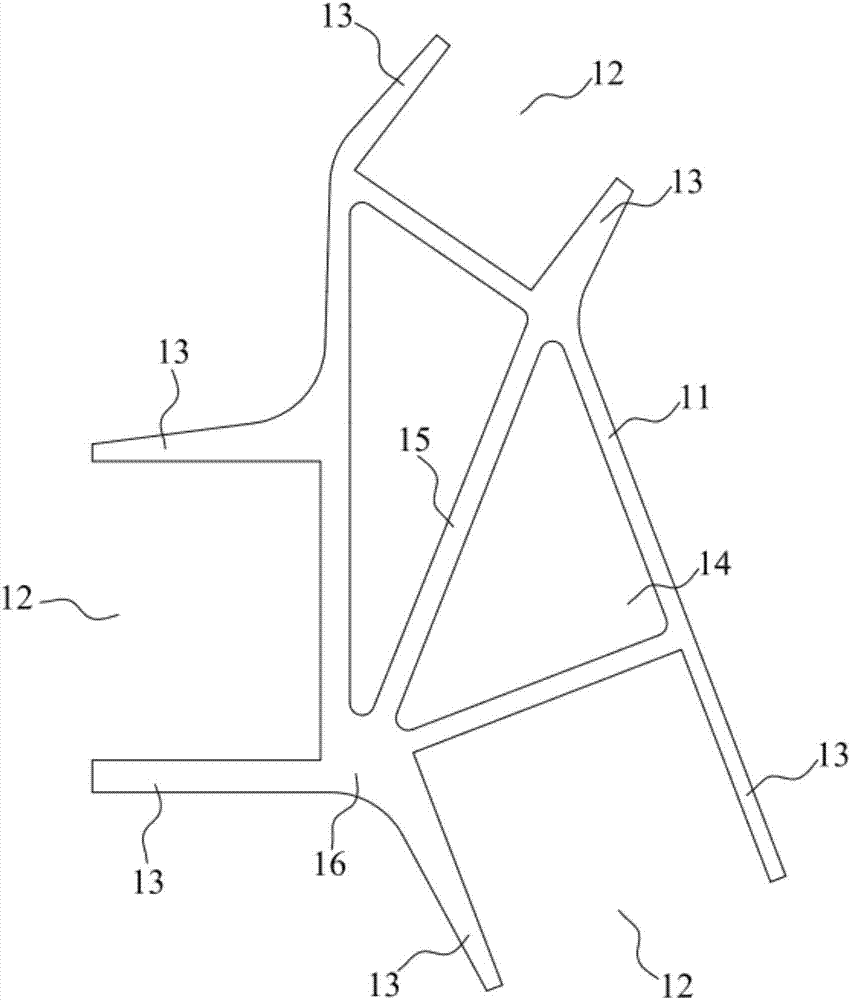

[0028] see Figure 1 to Figure 5 , the embodiment of the present invention provides an aluminum profile joint. The aluminum profile joint 1 includes a joint body 11. At least two interfaces 12 are arranged at intervals on the joint body 11 for connecting with the aluminum profile 2. Each interface 12 consists of two The opposite side plates 13 are formed by extending away from the joint body 11. The interior of the joint body 11 forms a hollow cavity 14, and a first rib 15 is arranged in the cavity 14, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com