Roller winch capstan force velocity measurement sensor hanging apparatus

A technology of speed measurement and hoisting device, which is applied in the direction of measuring device, linear/angular velocity measurement, tension measurement, etc. It can solve the problems of affecting the measurement accuracy, vibration of the force and speed measurement sensor, and difficult installation, so as to improve the measurement accuracy, convenience and accuracy measured effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

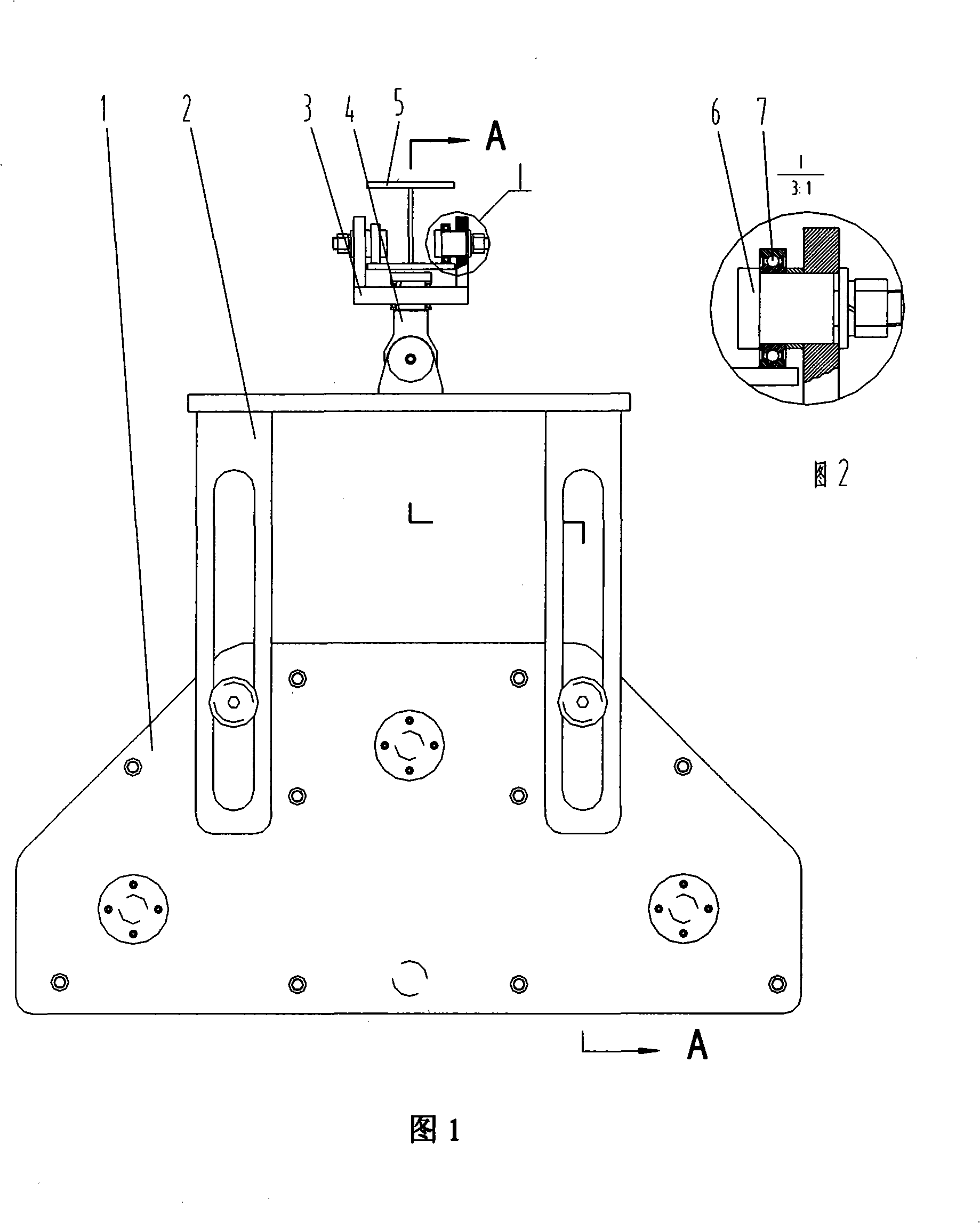

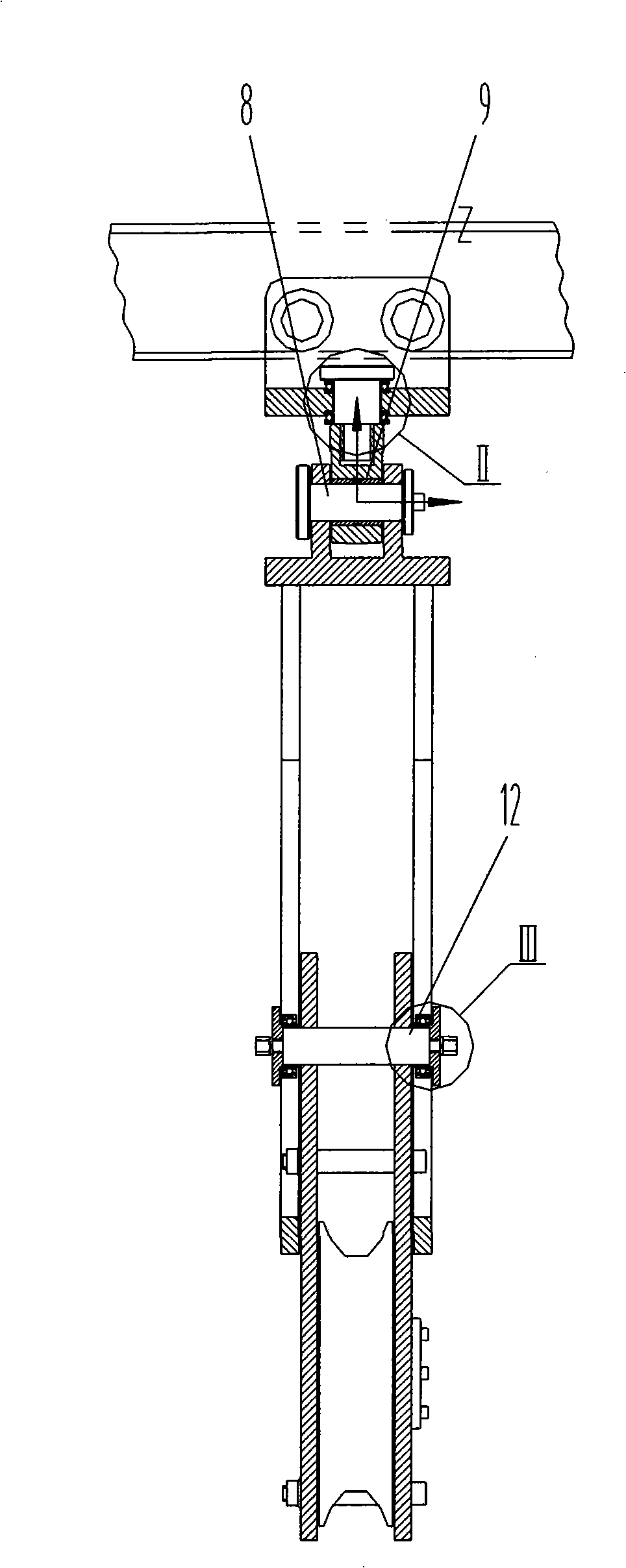

[0032] The hoisting device for the force and speed measurement sensor of the drum winch is composed of a hoisting frame, a force and speed measurement sensor 1 and a hoisting slideway 5; The hanger 2 is connected to the force speed measuring sensor 1, and the sliding frame 3 is assembled on the lifting slideway 5 and can move along the lifting slideway 5.

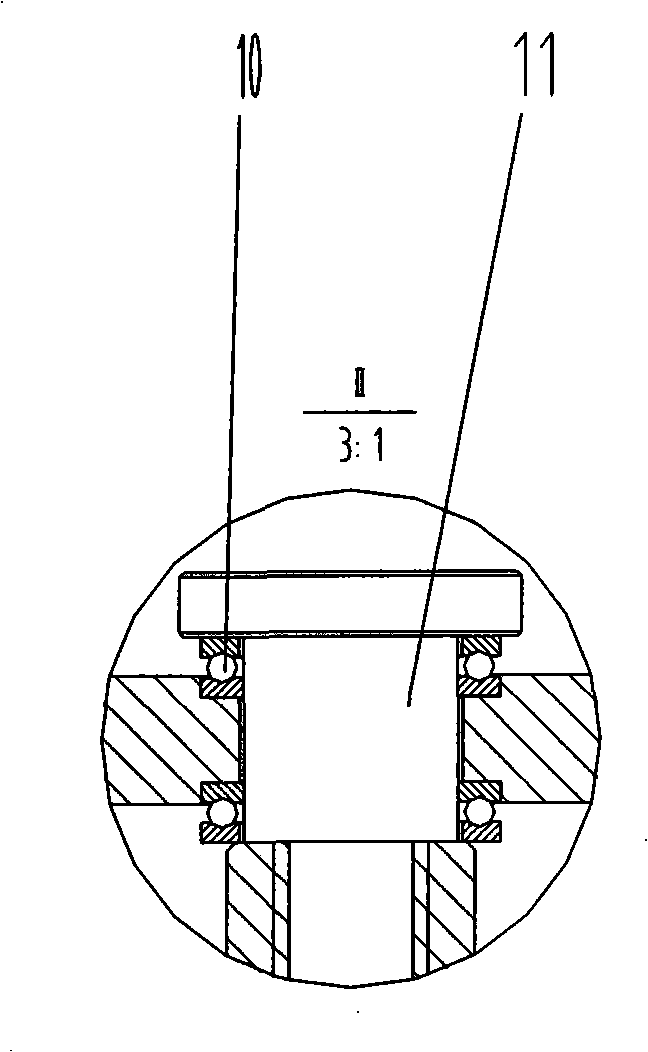

[0033] Annular groove is arranged on hanger 2 both sides plates, is symmetrically provided with two holes on force velocity measuring sensor 1, is worn with axle 12 in the hole, and axle 12 is assembled into one by bearing 13 and hanger 2 both sides plate annular grooves. The hanger 2 is connected with the trunnion 4 through the shaft 8 and the bushing 9 to form a rotary motion pair. The trunnion 4 is assembled on the sliding frame 3 through the shaft structure, and the shaft 11 is screwed into the trunnion 4 through threads, and the bearing 10 is connected with the sliding frame 3 in the middle to form a rotary motion pair...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com