Movable sink parts washer

A technology for cleaning tanks and parts, which is applied in the field of parts cleaning machines with movable cleaning tanks, and can solve problems such as metal corrosion and shape change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The invention is not limited to specific details of the described apparatus or methods, and other modifications and applications may be envisioned. Further variations may be made in the methods and apparatus described above without departing from the true spirit of the scope of the inventions herein referred to. Accordingly, it is intended that the subject matter in the foregoing description be regarded as illustrative rather than restrictive.

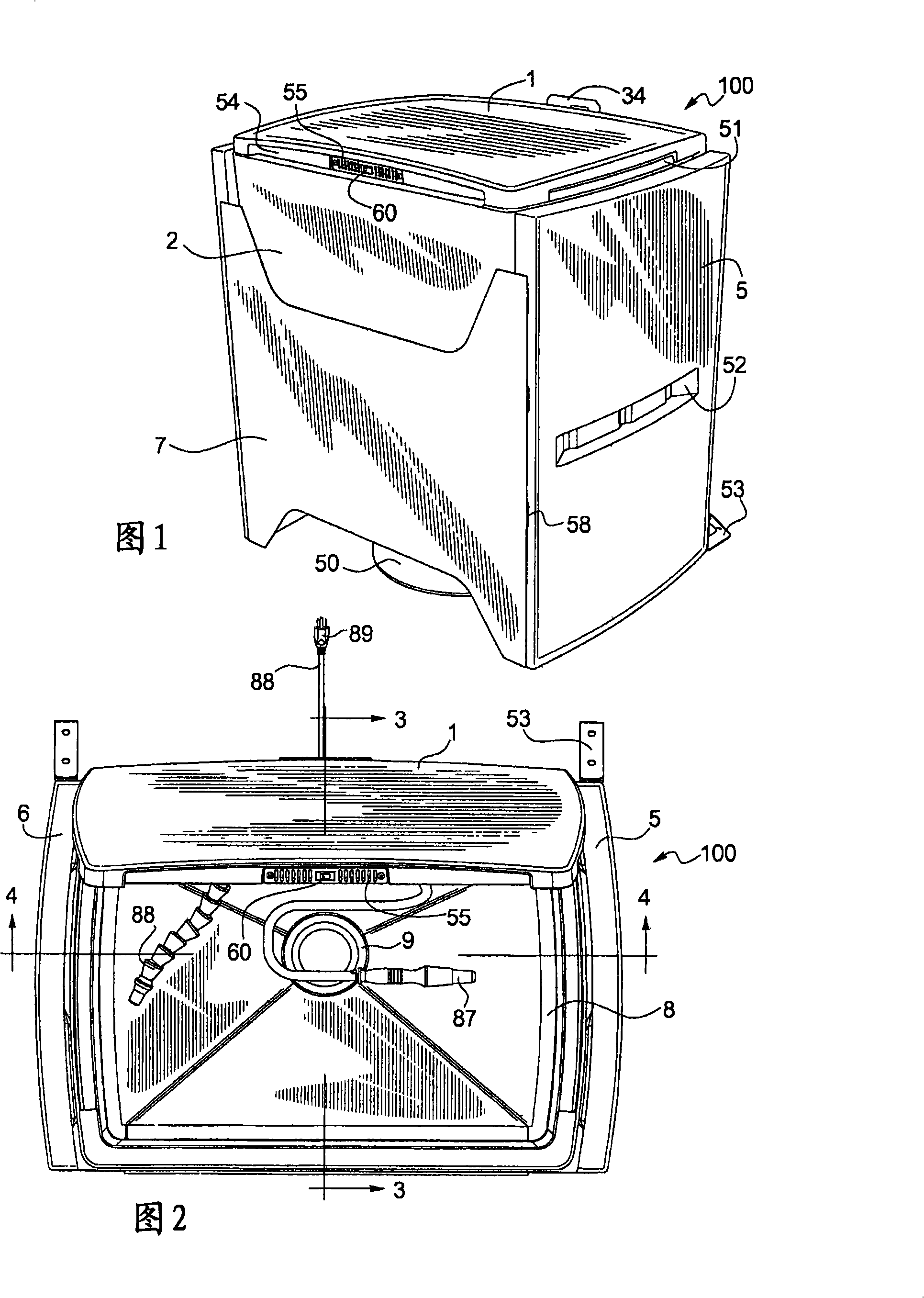

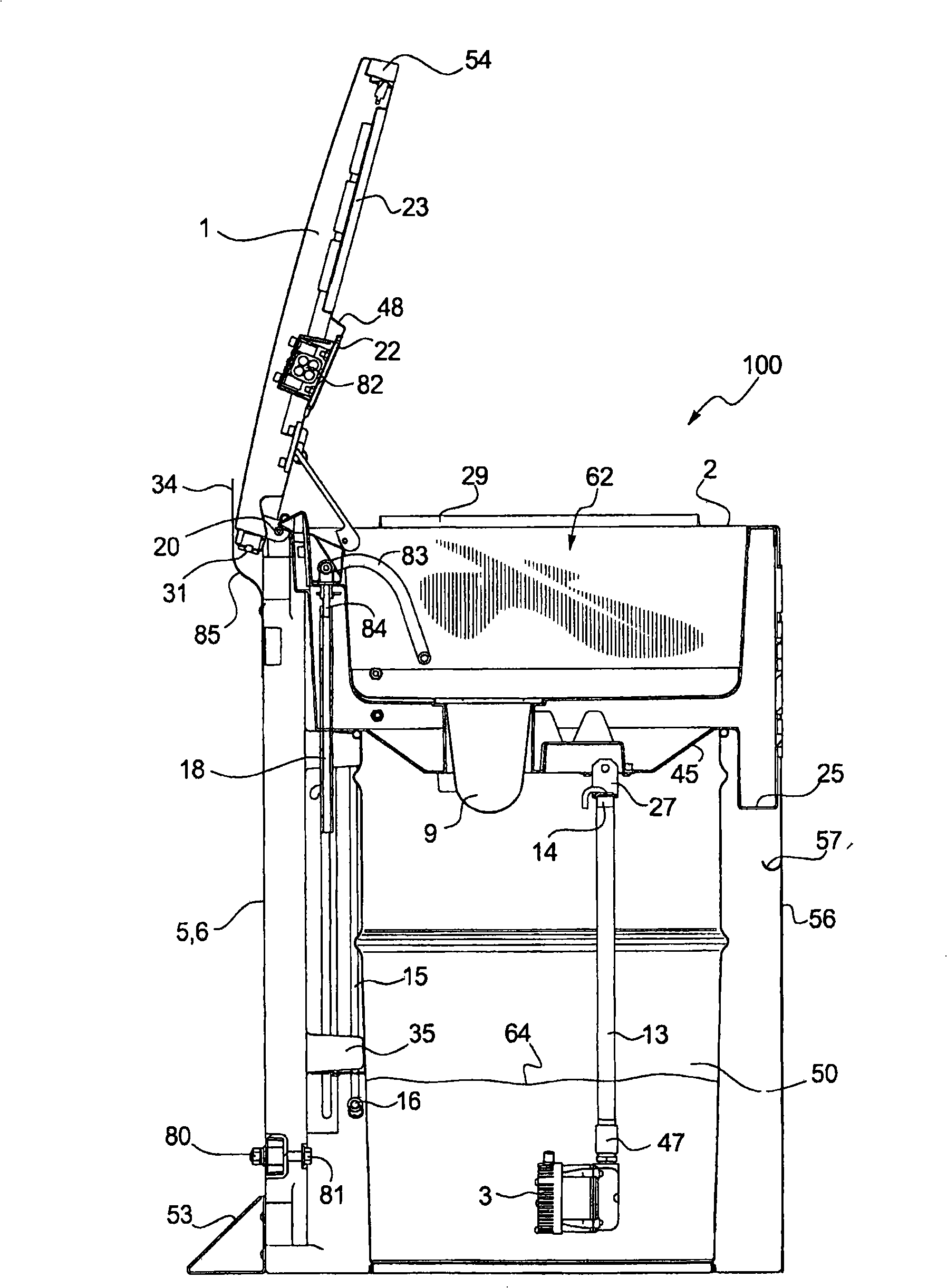

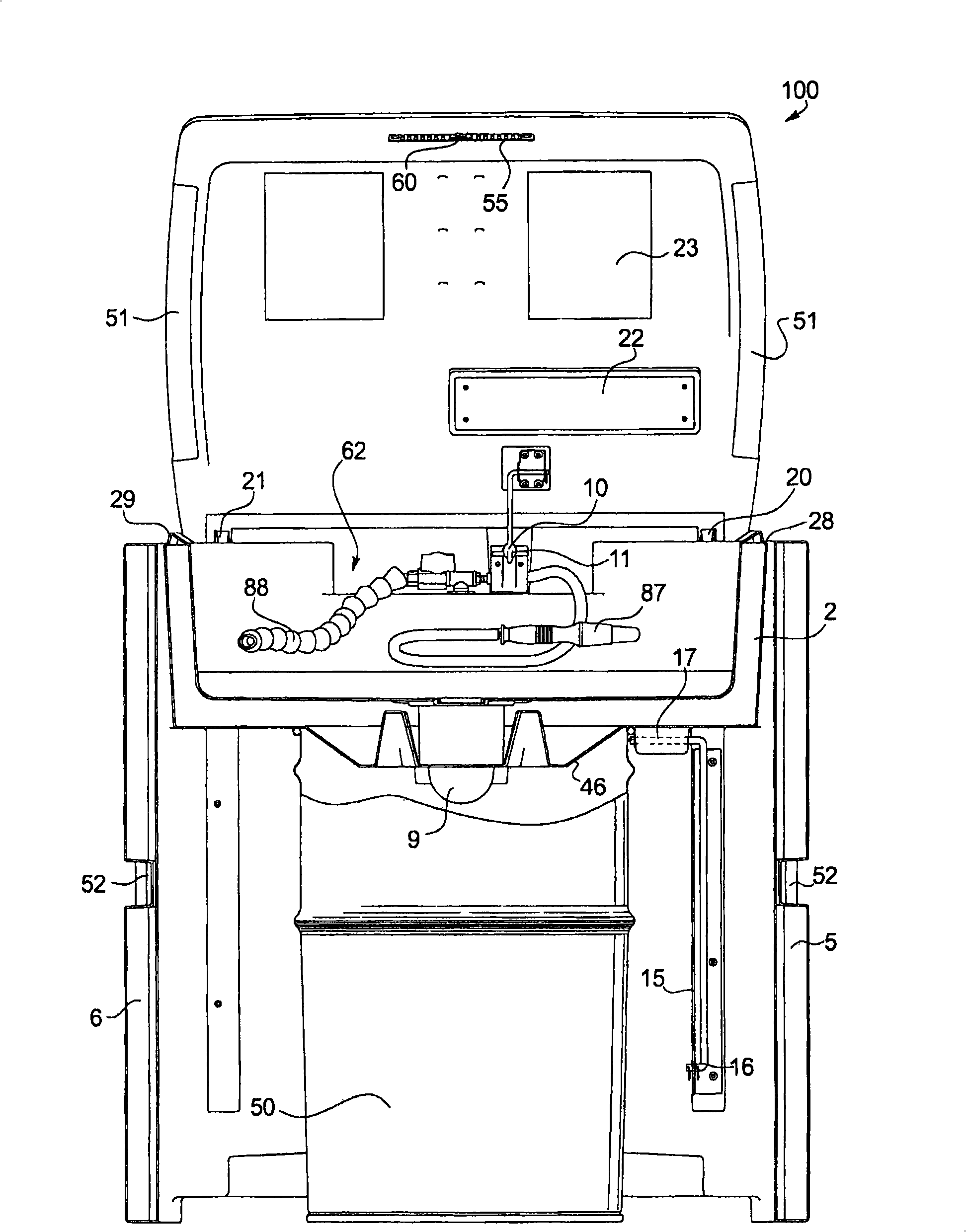

[0025] Shown in FIGS. 1-10 is a new compact articulated manual parts washer 100 . The parts washer 100 is a compact and easy-to-clean unit designed for quick access and quick replacement of the washer fluid reservoir 50, and has several improved features associated with the compact design. In one embodiment, the housing is constructed from a plurality of interlocking molded hollow polymer parts assembled to form a chamber consisting of the cover 1 , wash tank 2 , shell panels 5 , 6 and front panel 7 containing the circulating c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com