Construction method of concrete floor prefromed opening of dust-free chamber workshop

A construction method and concrete technology, which is applied to the preparation of floor slabs, formwork/formwork/work frames, and building components on site, and can solve problems such as deformation, inability to provide dimensional accuracy openings, and poor structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

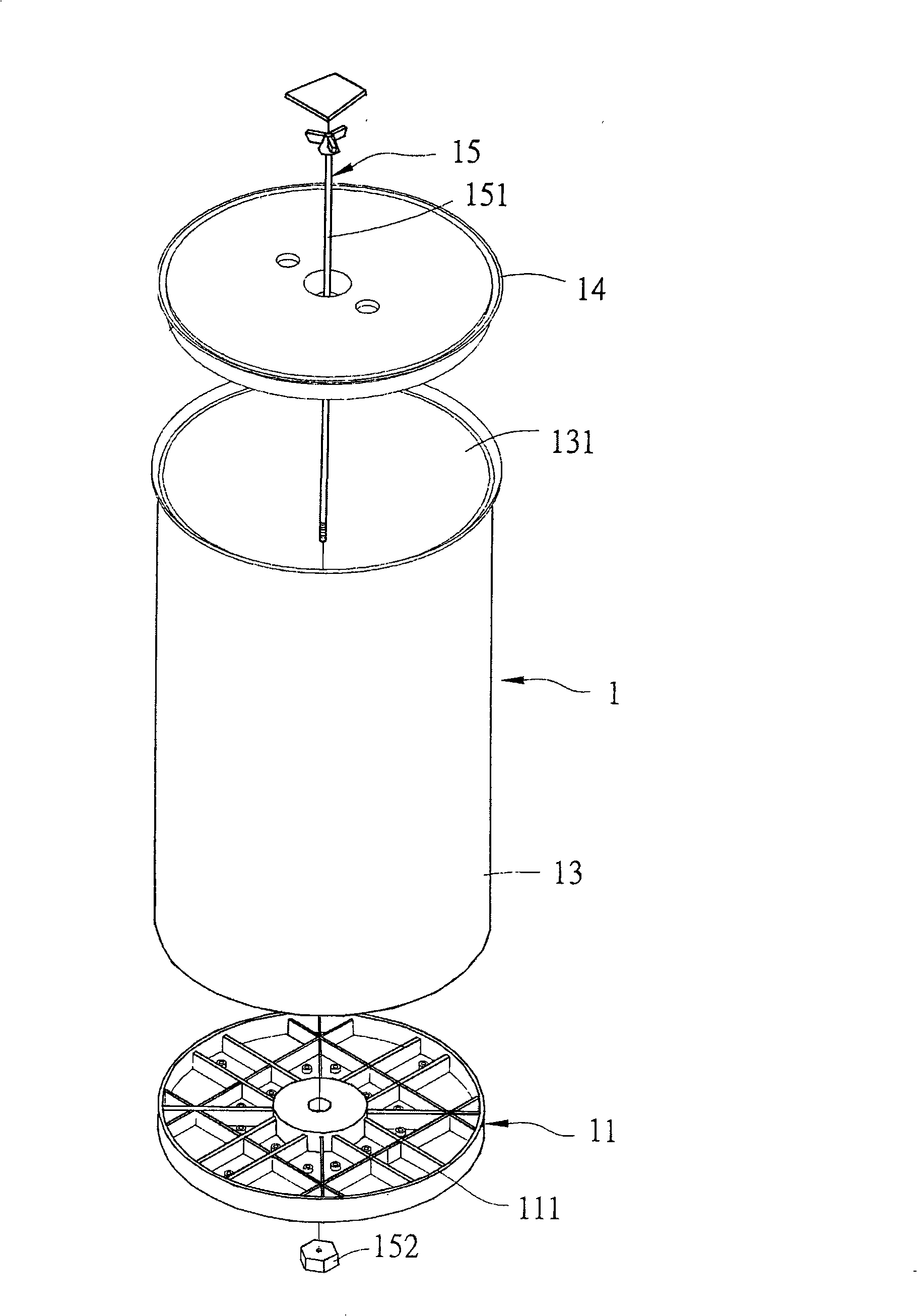

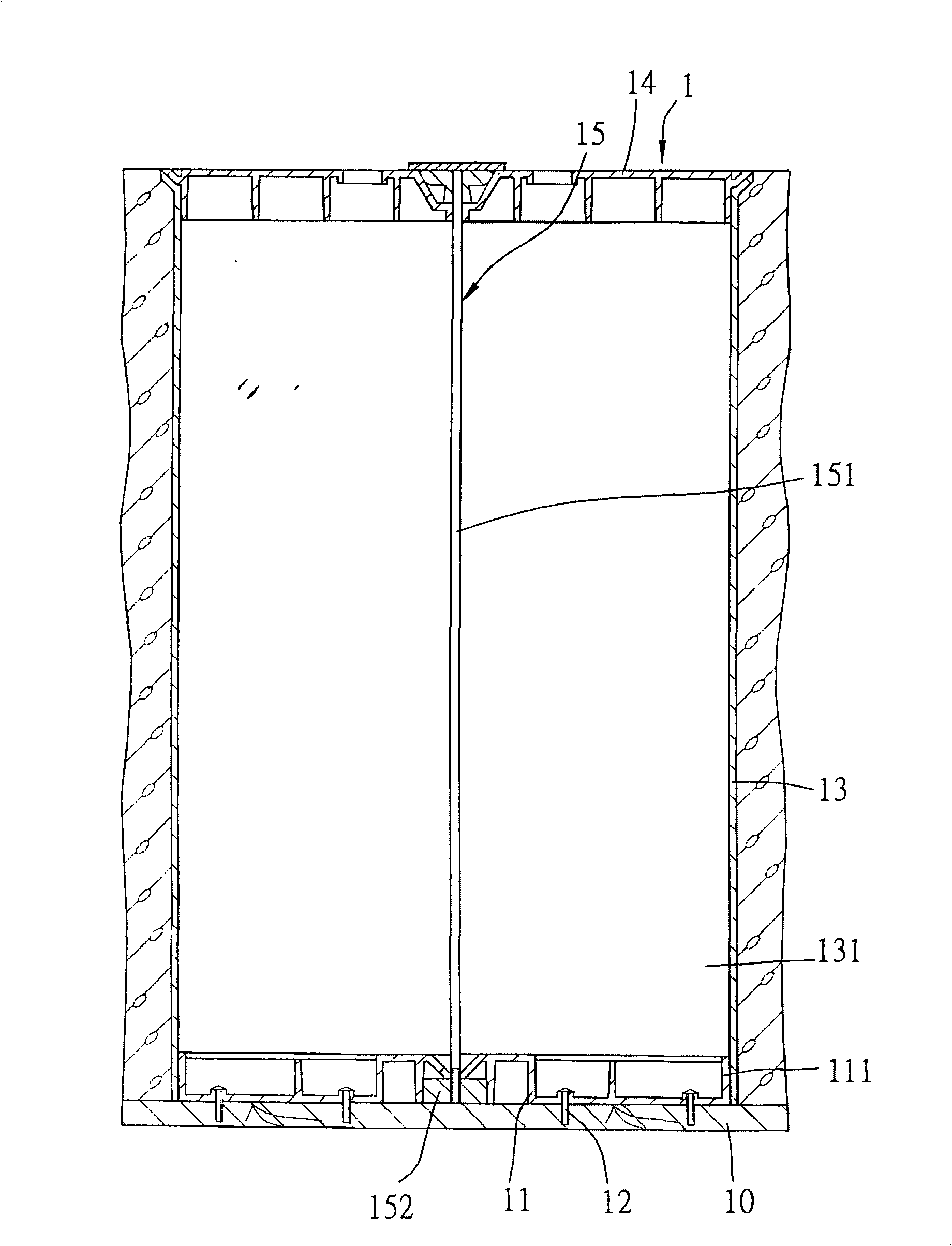

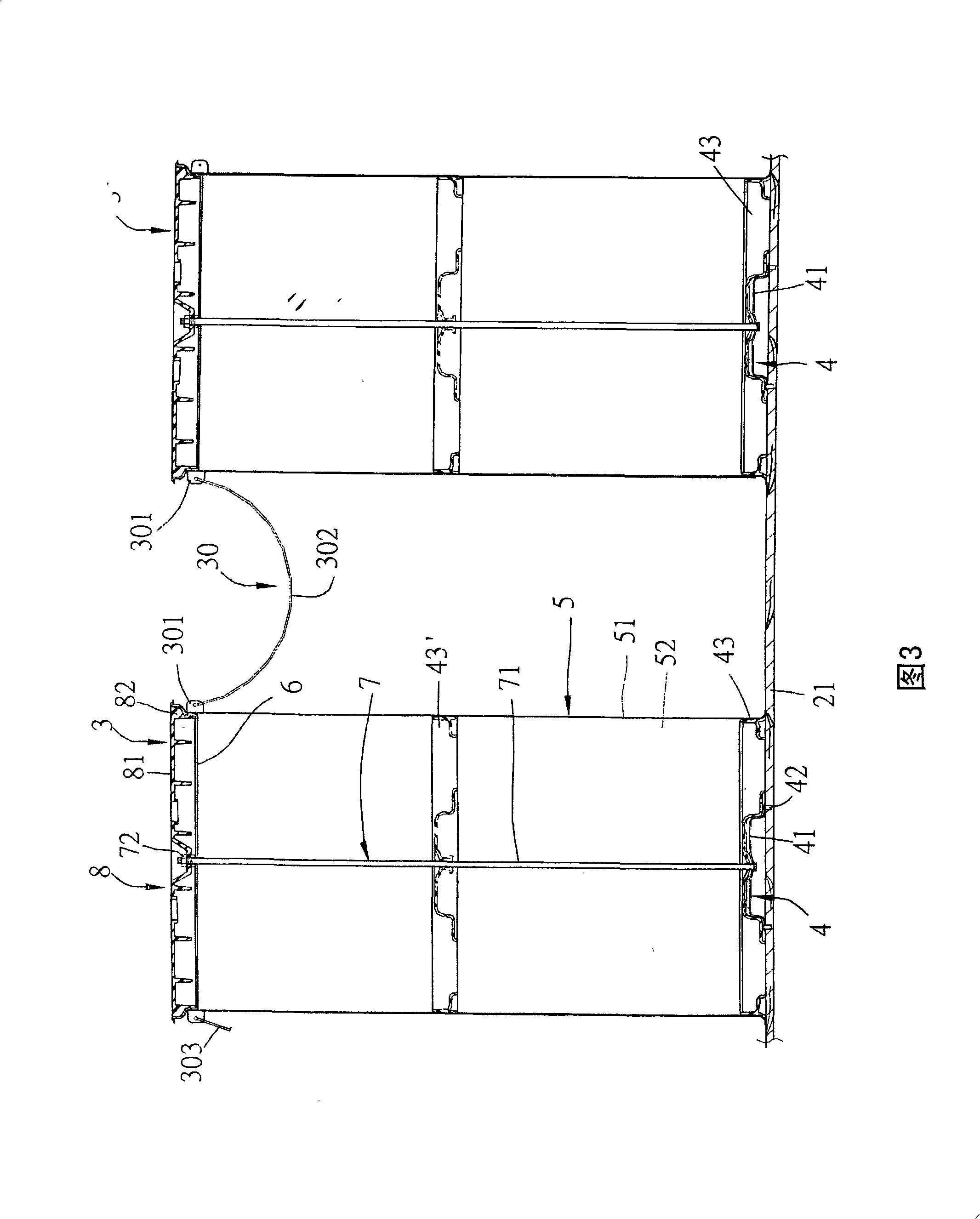

[0039] See Figure 3, Figure 4 5, a preferred embodiment of the molding device of the present invention is installed on a formwork 21, when concrete is poured above the formwork 21 and solidified, a concrete floor 22 can be formed, and the floor 22 is preset The concrete floor slab can be a general on-site construction floor slab or a precast floor slab.

[0040] The molding device of the present invention includes: several first molding assemblies 3, several second molding assemblies 3', and several conductive units 30 connected between these molding assemblies 3, 3' and having an electrostatic grounding function . Wherein the conductive unit 30 includes: two metal conductive parts 301 respectively fixed on the molding assemblies 3, 3', a copper wire 302 connected between the conductive parts 301, and a first The ground wire 303 of the molding assembly 3 is grounded, so that the metal components on the molding device have the function of electrostatic conduction. These mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com