System and method for testing image sensing wafer stain and

An image sensing and stain detection technology, applied in measurement devices, image communication, optical testing flaws/defects, etc., can solve the problems of large subjective factors of detection methods and lower detection qualification rate, so as to improve the detection qualification rate and avoid subjective factors, the effect of overcoming the effects of noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to further illustrate the present invention, a preferred embodiment is given and described in detail below with accompanying drawings.

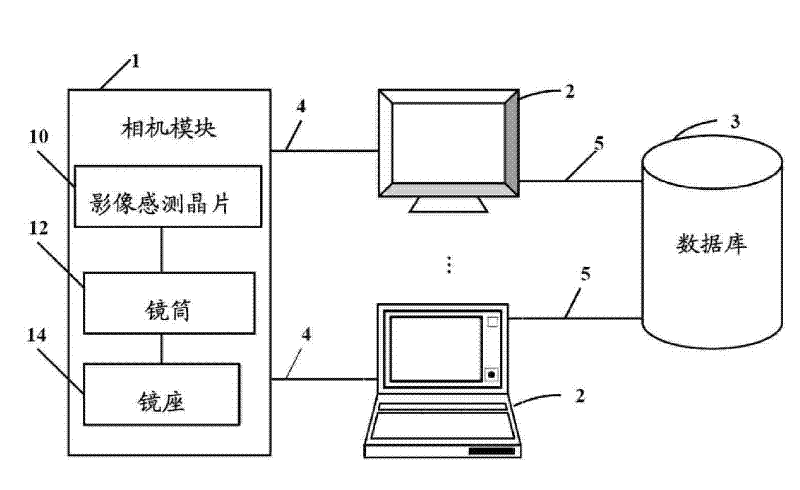

[0016] like figure 1 Shown is a hardware architecture diagram of a preferred embodiment of the image sensing wafer stain testing system of the present invention. The image sensing wafer stain testing system (hereinafter referred to as “the system”) is built in a plurality of computers 2 . The computer 2 is electrically connected to an image sensing chip 10 to obtain an image through an image data line 4 , and after performing a corresponding test on the image, the test result is output to the database 3 through the connection 5 for storage. The connection 5 is a database connection, such as an open database connection (Open Database Connectivity, ODBC), or a Java database connection (Java Database Connectivity, JDBC).

[0017] In this embodiment, the image sensing chip 10 to be tested is accommodated in a camera module 1 , u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com