Battery module

A technology of battery modules and unit cells, which is applied in the direction of batteries, battery pack components, circuits, etc., can solve the problems that it is difficult to prevent the position of the unit cells from changing, it is difficult to keep the installation position unchanged, and the uneven deformation of the battery module is achieved. Shorten working hours, prevent irregular changes in performance, and improve productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

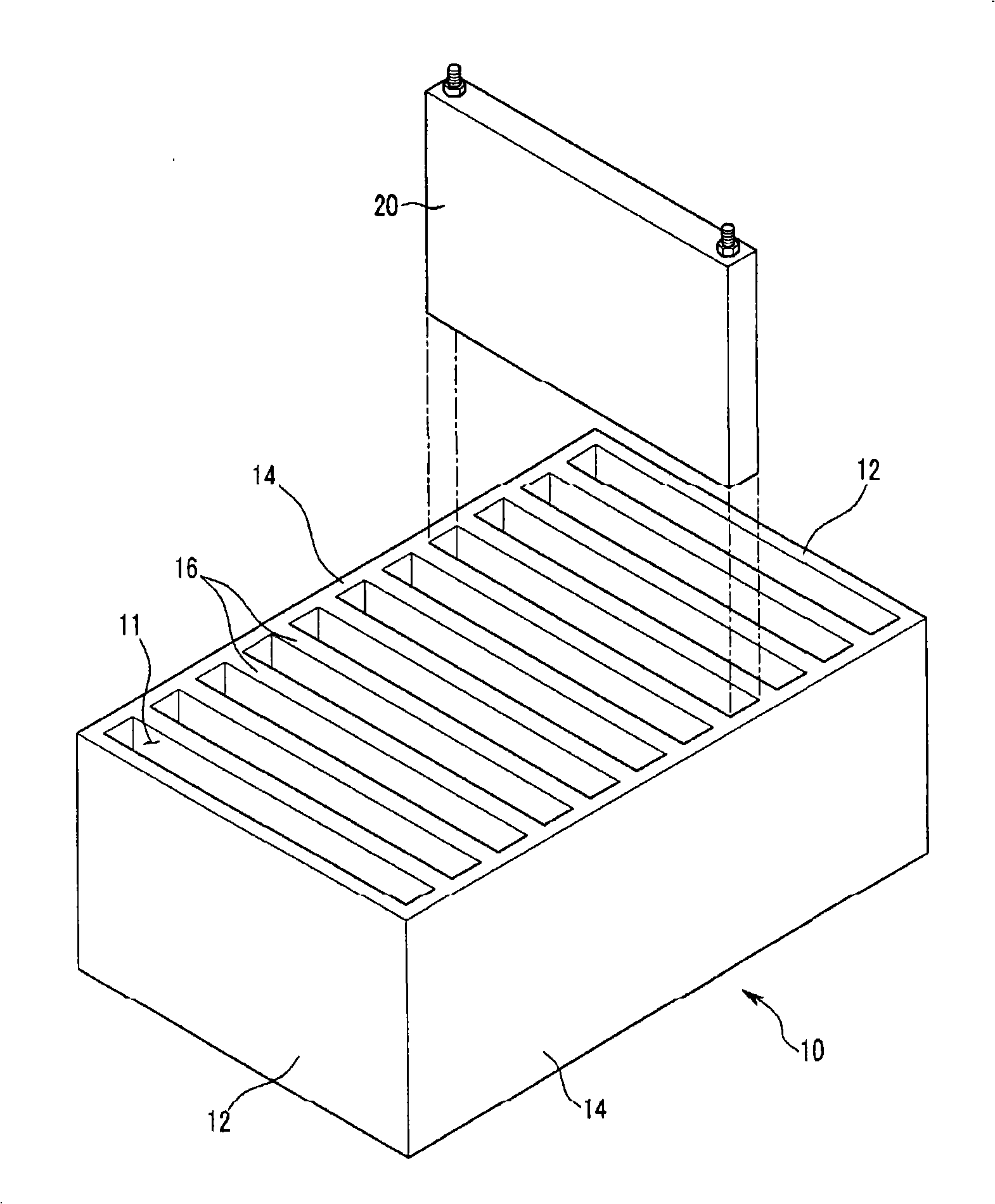

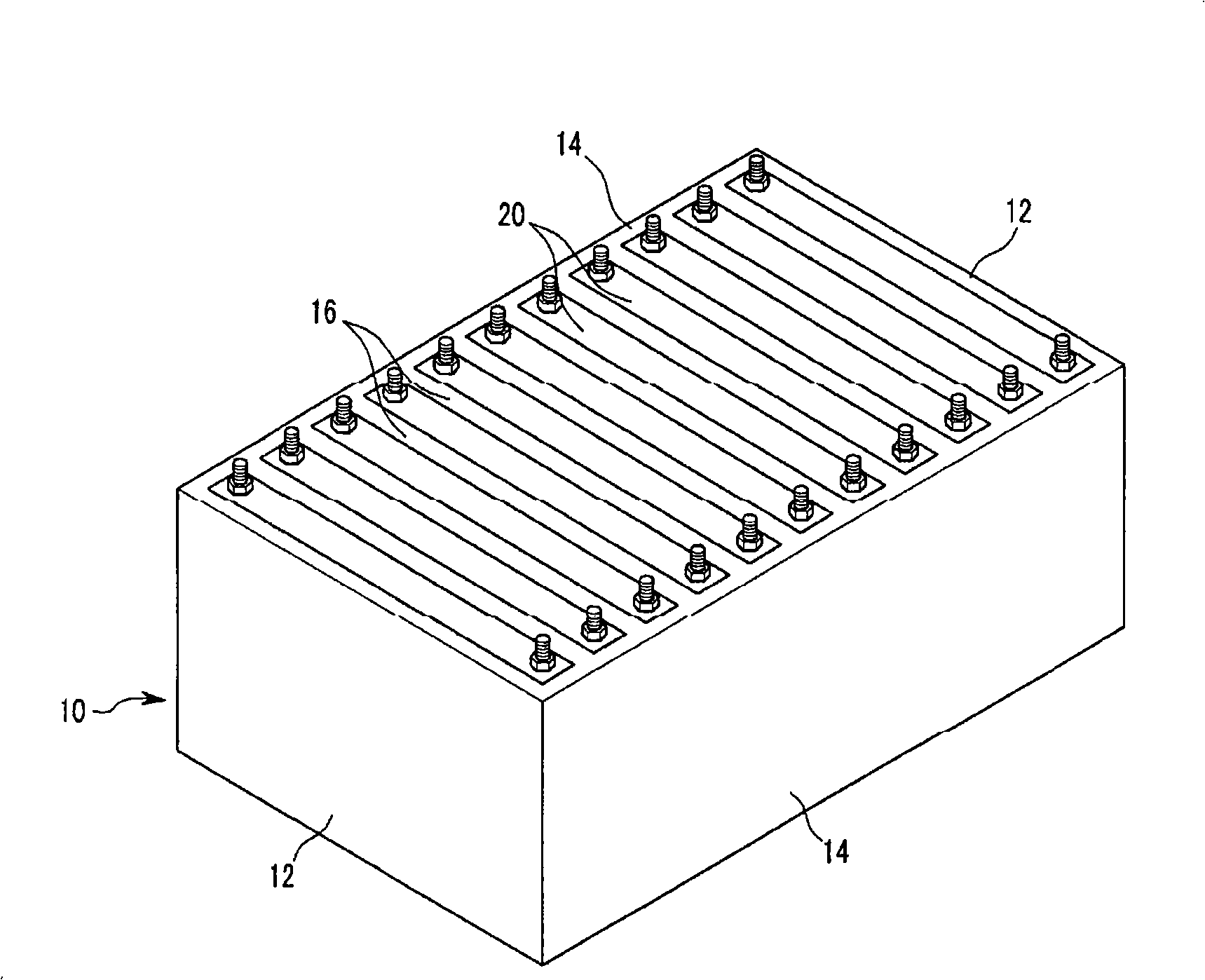

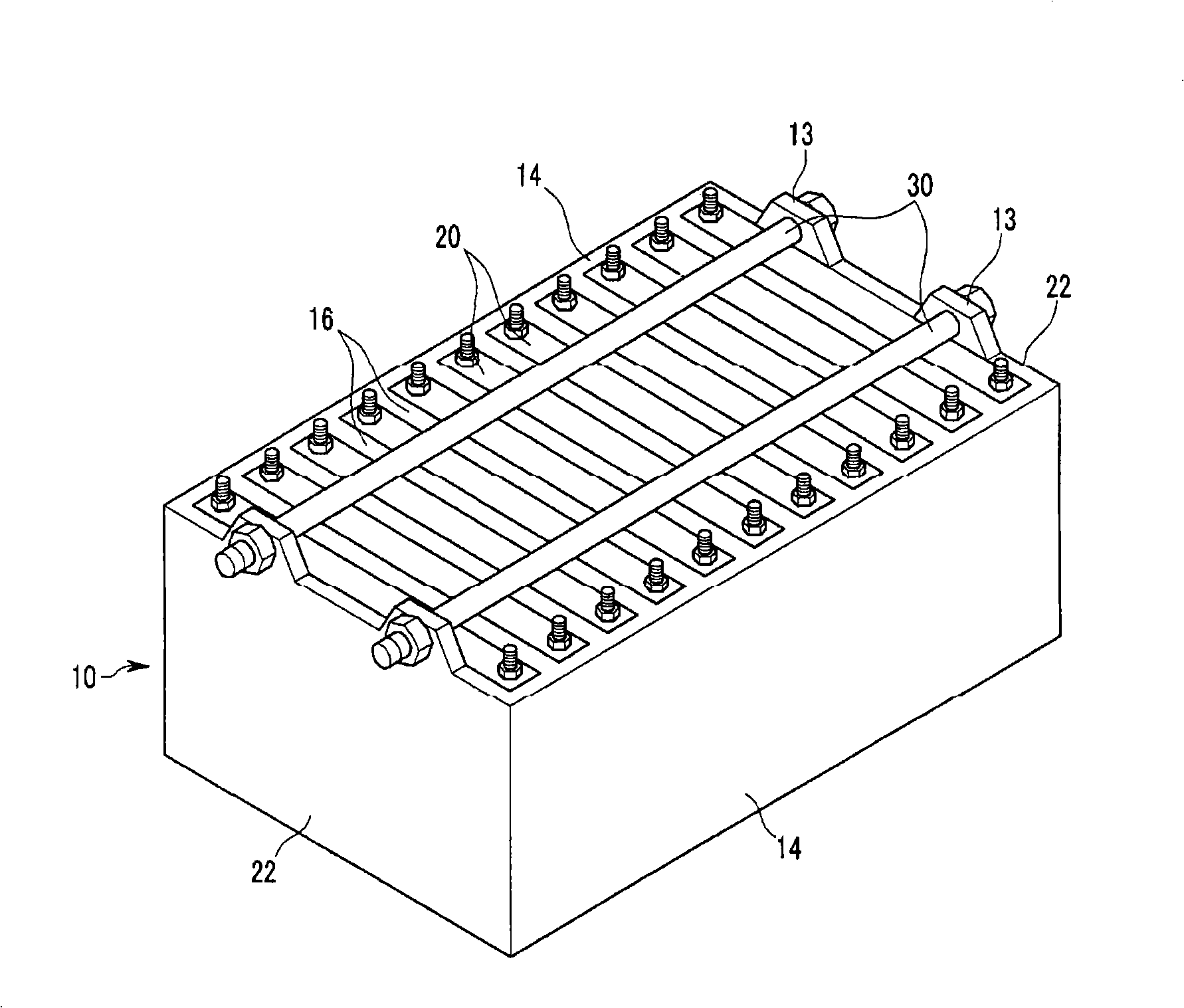

[0049] now refer to figure 1 and 2 , the battery module of the present embodiment includes a box-shaped case 10 with at least one side open, a plurality of partition walls 16 integrally formed in the case 10 at certain intervals, and a plurality of partition walls 16 separated from each other by the partition walls 16 and inserted thereinto. A unit cell 20 in the casing 10 .

[0050] As described above, since the plurality of partition walls 16 are installed in the case 10 at intervals, spaces 11 are formed between the partition walls 16 to insert the unit cells 20 therein.

[0051] The housing 10 has a pair of support plates 12 formed to face each other at both ends of the housing and a pair of side plates 14 connected to the support plates 12 at both ends thereof and to two sides of each partition wall 16. The edges are fixed together. The support plate 12 of the housing 10 is installed parallel to the partition wall 16 , while the side plate 14 is installed vertically to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com