Closed container lid with exposed liner

A technology for airtight containers and container lids, applied in the directions of removable lids/covers, closures, clamping devices, etc., can solve the problems of liner falling off, inability to carry out, unclean and hygienic, etc., to prevent arbitrary falling off and reduce manufacturing difficulty , The effect of preventing random shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

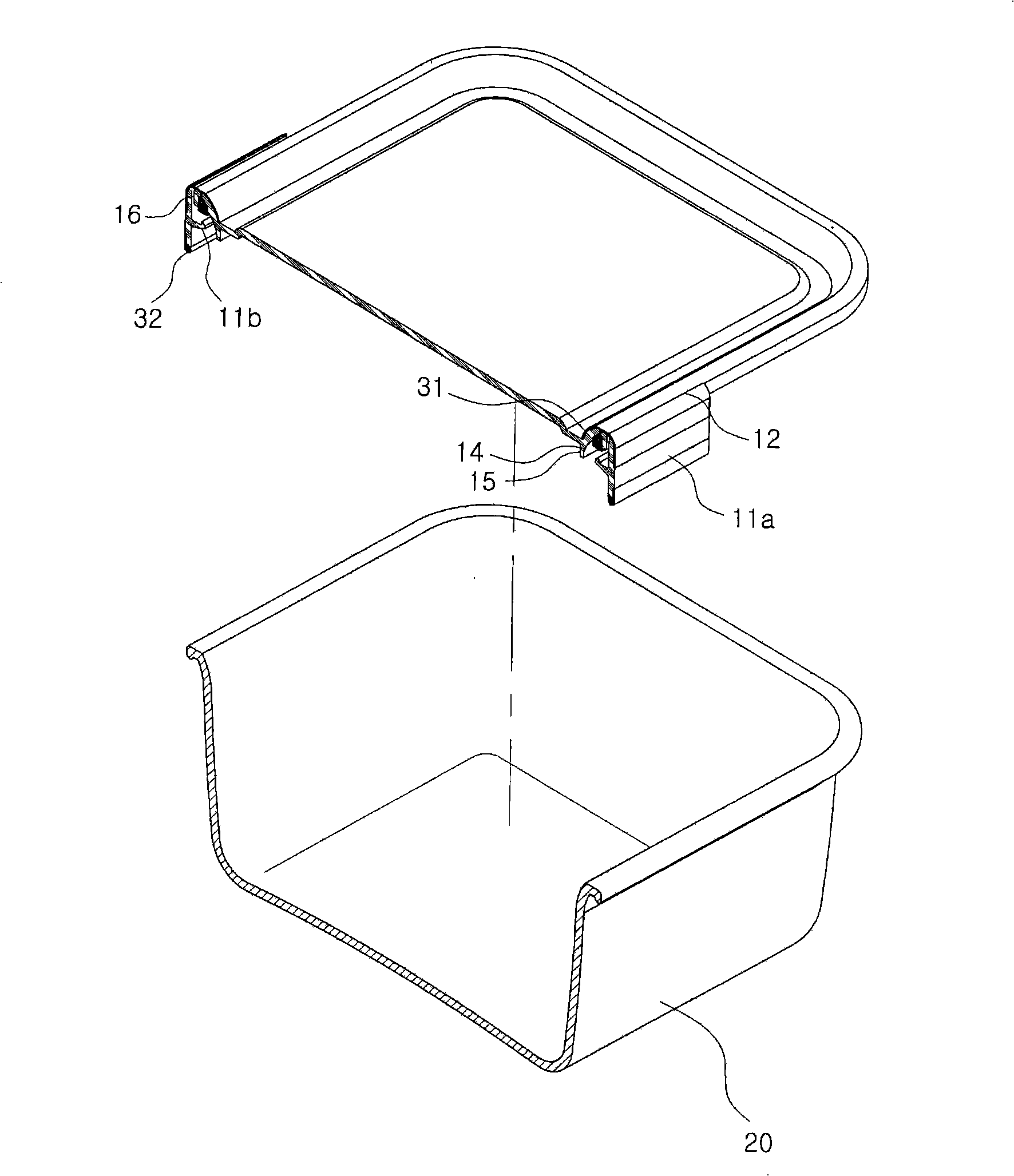

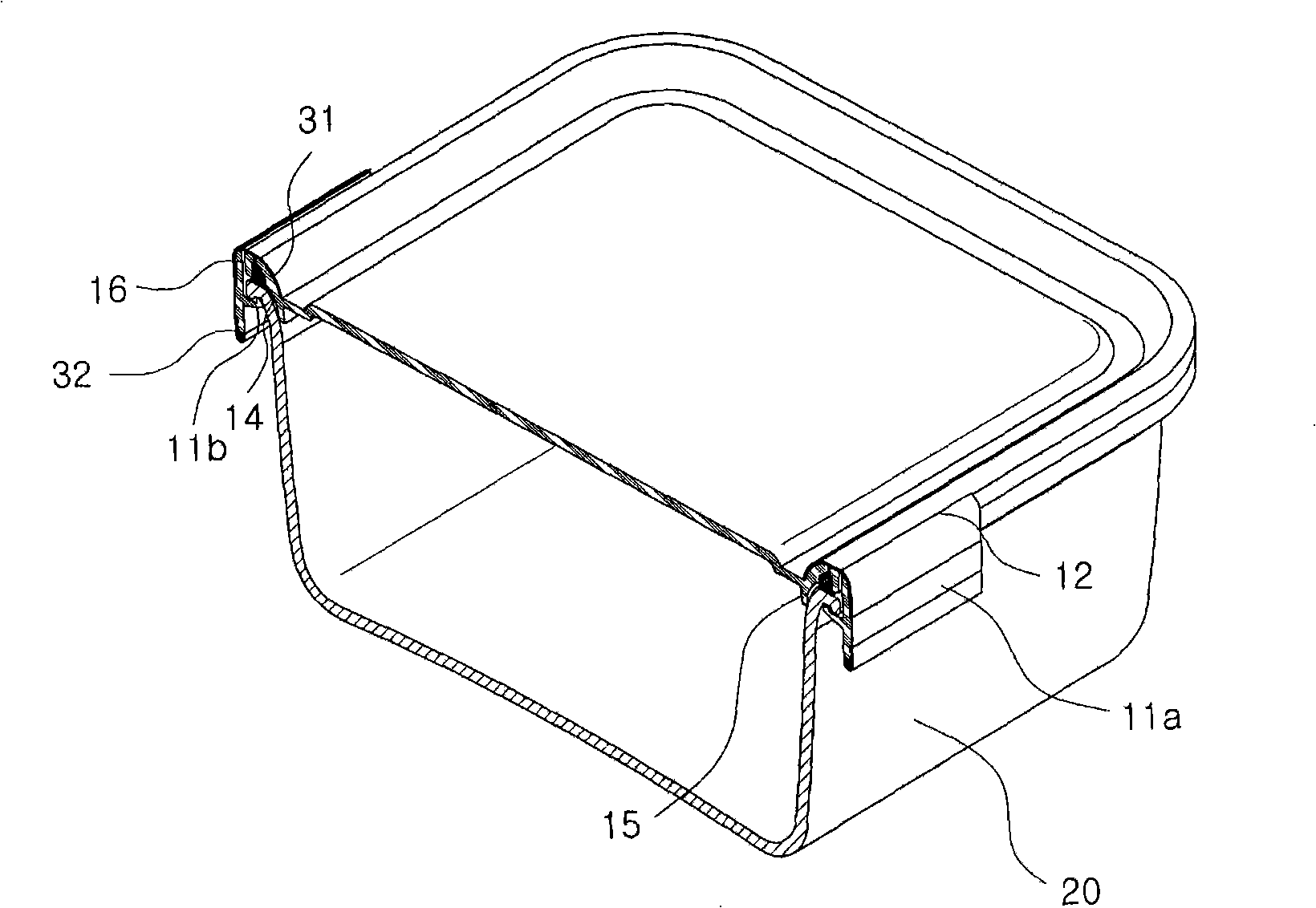

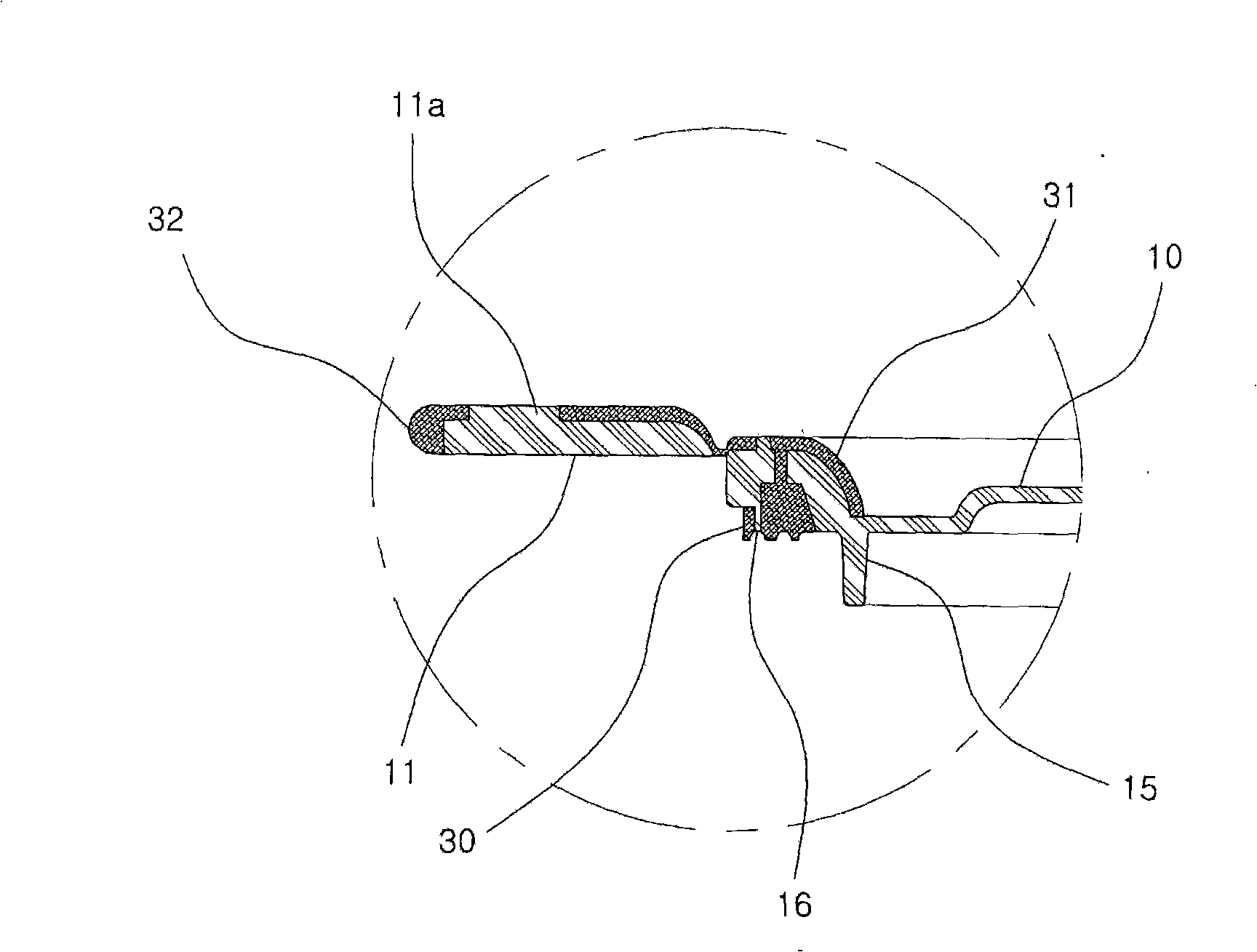

[0026] Such as figure 1 and figure 2 As shown, in the composition of the present invention, the container cover (10) and the container main body (20) are exposed to the inside of the pressure surface (14) of the container cover (10) by means of the folded connecting device (11) in the container cover (10) The formed liner (30) is pressurized to be airtight, and the pressure surface (14) formed on the container cover (10) where the above-mentioned liner (30) is located is in a state of close contact with the flange formed around the upper end of the container body, The liner (30) is on the inner side of the above-mentioned pressurizing surface (14), and is exposed on the inner side of the container cover (10) through the through hole (17) of the container cover (10) by means of double injection molding, and a coating (31) is formed on the outer side. ).

[0027] At this time, the periphery of the upper end of the container main body (20) is protrudingly formed by a curved f...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap