Flying shear machine upper and lower knife rack gear drive device

A technology of gear transmission mechanism and flying shear machine, which is applied in the direction of gear transmission device, transmission device, belt/chain/gear, etc., which can solve the problems of meshing gear misalignment and impact, and achieve the elimination of meshing gap, elimination of clearance, and overcoming transmission error Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

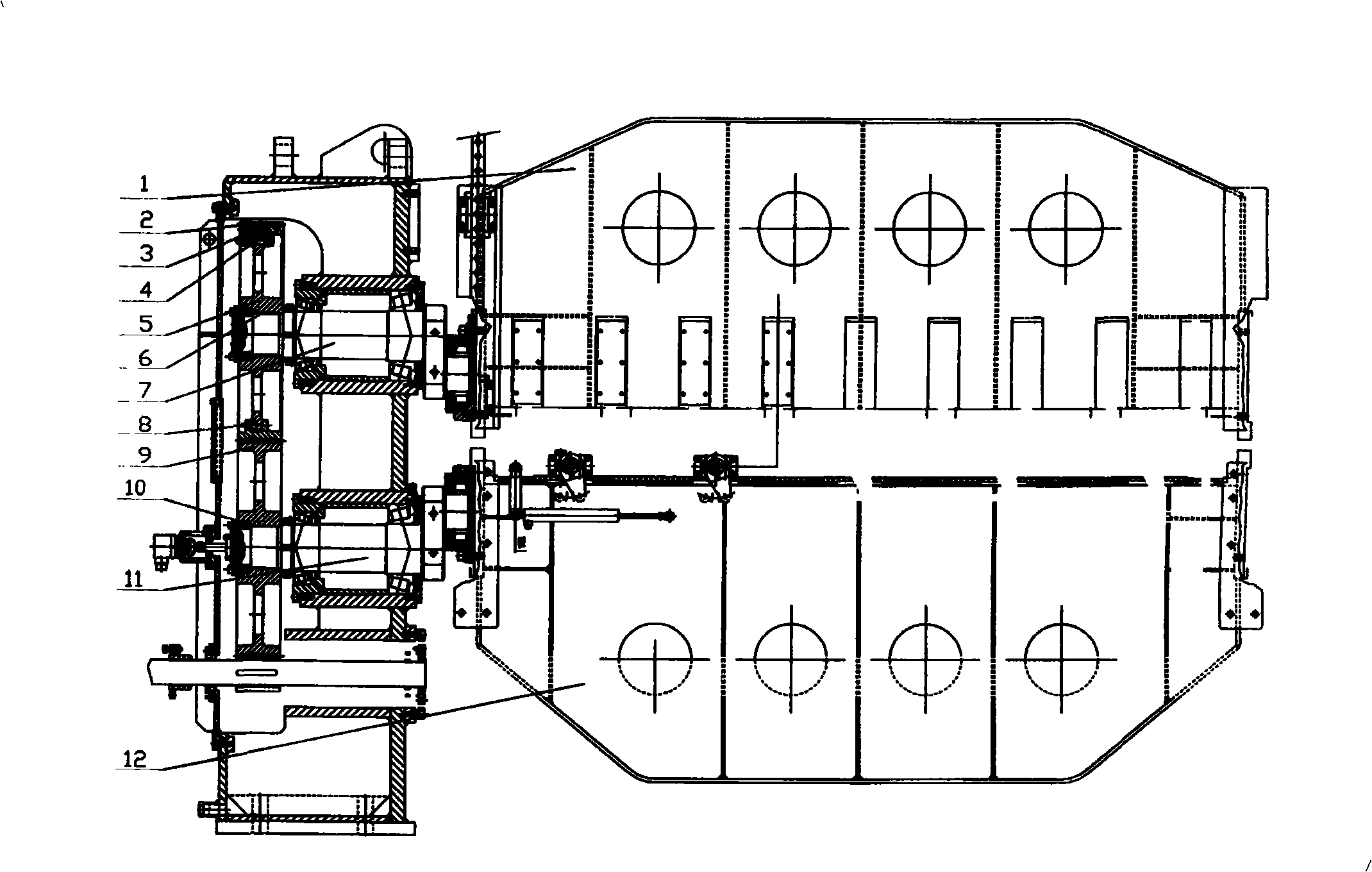

[0020] Such as figure 1 , the present invention includes the main transmission gear, the lower tool rest transmission gear 9 and the upper tool rest transmission gear which are arranged on the main transmission shaft, the upper tool rest eccentric shaft 7 and the lower tool rest eccentric shaft 11, and the upper tool rest transmission Gear is made of wheel core 5, main gear 2, pinion gear 3, eccentric adjustment shaft 8 and bolt 4, and wheel core 5 is connected with upper knife rest eccentric shaft 7.

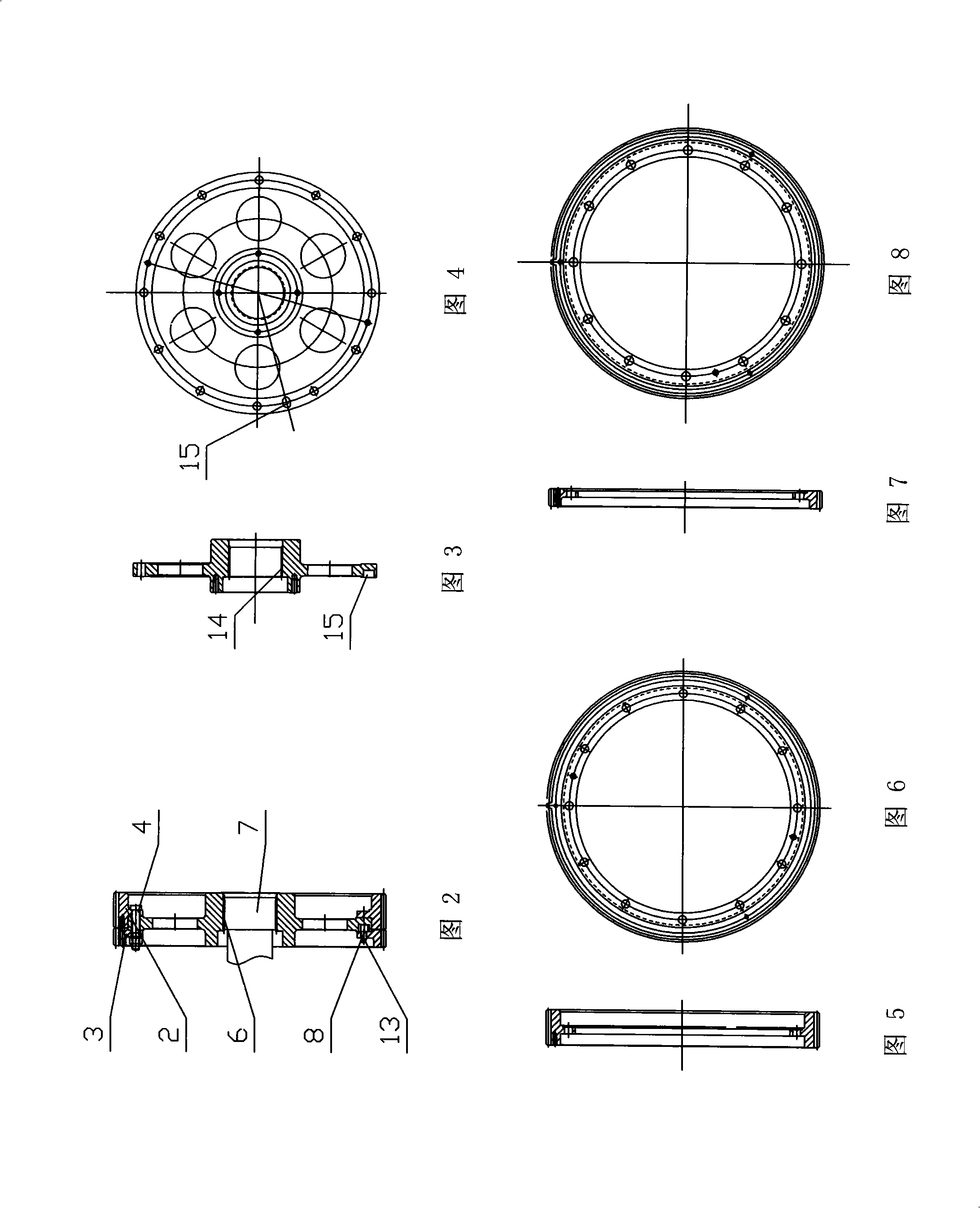

[0021] As shown in Figures 2 to 8, the main gear 2 and the pinion gear 3 are sequentially arranged on the outer ring of the wheel core 5 from the inside to the outside; an eccentric adjustment shaft 8 is set between the pinion gear 3 and the wheel core 5; the wheel core 5, the main gear 2, A number of connecting holes are respectively arranged on the same circumference of the auxiliary gear 3, and the apertures of the connecting holes on the auxiliary gear 3 are slightly larger...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com